In promoting green agricultural development, NPK compound fertilizer production lines play a key role, providing strong support for sustainable agricultural development.

Traditional fertilization methods often lead to soil degradation and environmental pollution due to nutrient imbalances and low utilization rates. However, NPK compound fertilizer production lines, through scientific processes, produce high-quality fertilizers that meet the needs of green agriculture.

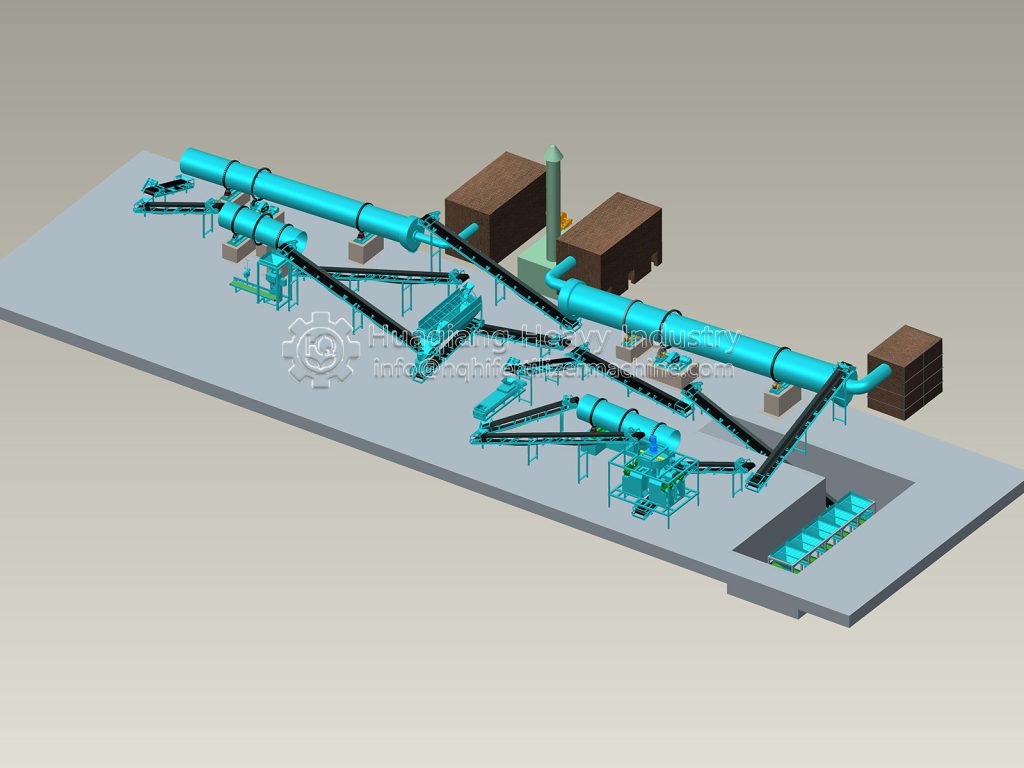

The production line prioritizes the use of natural and renewable raw materials, reducing reliance on synthetic raw materials. Raw materials are meticulously processed to remove impurities, improving fertilizer quality while minimizing environmental risks. Production emphasizes precision fertilization. By precisely controlling the ratios of nitrogen, phosphorus, potassium, and other elements, formulas can be customized for different crops and soils, maximizing crop needs while minimizing waste and pollution.

The production line features environmentally friendly technologies: advanced dust and odor removal equipment reduces dust and odor emissions; energy-saving equipment and processes reduce energy consumption, enabling recycling and green production. This type of fertilizer also improves soil structure. The appropriate nutrient supply promotes soil microbial growth, increases organic matter content, enhances soil fertility and water and fertilizer retention, and reduces soil erosion.

With growing consumer demand for green agricultural products, the fertilizer produced by this production line helps farmers cultivate high-quality crops, increasing the added value of agricultural products and farmers’ income while also meeting market demand for healthy food.

With its scientific production and environmentally friendly approach, the NPK compound fertilizer production line has become a key driver of green agricultural development. It will continue to innovate and contribute to the green transformation of agriculture.