In today’s pursuit of sustainable development, the innovative organic fertilizer production line represents a significant advancement in agriculture and environmental protection. This sophisticated organic fertilizer line efficiently transforms various organic wastes into valuable resources, achieving a remarkable conversion from waste to wealth. By implementing these systems, we can reduce environmental pollution while creating nutrient-rich fertilizers that support healthy soil ecosystems and sustainable farming practices.

What is an Organic Fertilizer Production Line?

The organic fertilizer line is a complete industrial process specifically designed to convert organic waste (such as livestock manure, agricultural waste, urban sludge, etc.) into efficient organic fertilizers. Through a series of biochemical and physical processes, this production line can stabilize the nutrients in organic waste and produce high-quality organic fertilizers beneficial for crop growth.

Modern organic fertilizer production lines not only solve the problem of waste disposal but also promote the sustainable development of agriculture, achieving a win-win situation for both economic benefits and ecological protection.

Dual Benefits for Environment and Agriculture

Waste Resource Utilization

Transforms potentially environmentally polluting organic waste into valuable resources, reducing landfill burden

Soil Improvement

The produced organic fertilizer can improve soil structure, enhance soil fertility and water retention capacity

Pollution Reduction

Effectively treats organic waste, reducing greenhouse gas emissions such as methane and groundwater pollution risks

Circular Economy

Achieves nutrient cycling “from land to land”, promoting sustainable agricultural development

Production Process and Technical Highlights

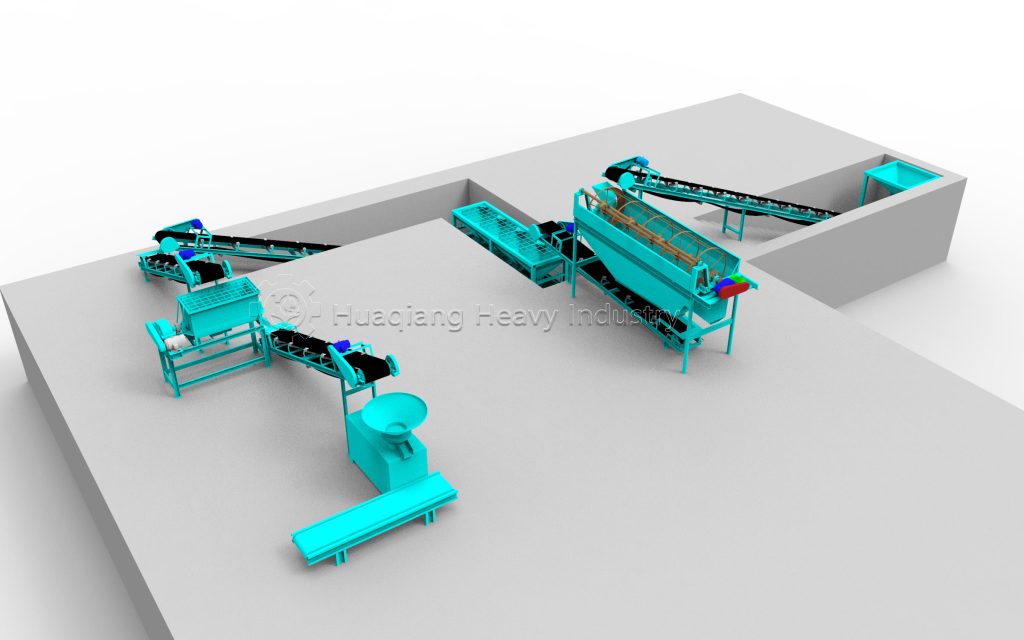

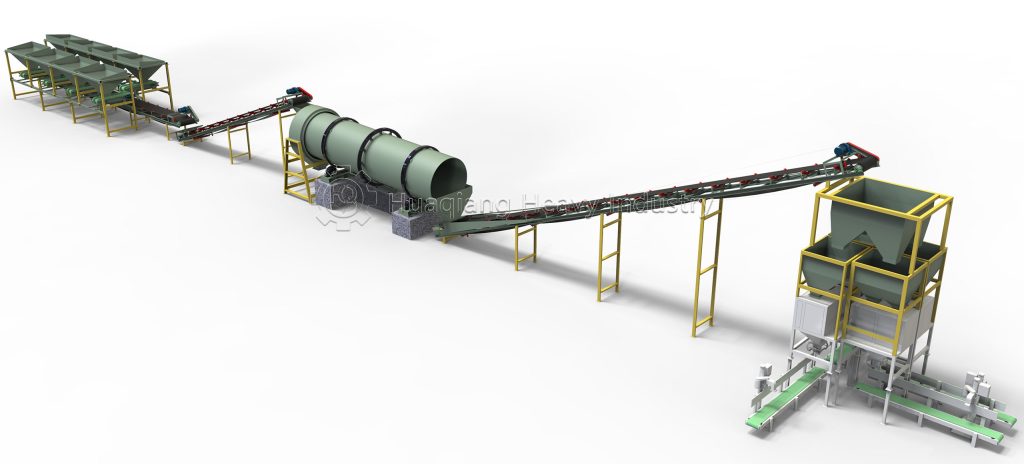

A complete organic fertilizer line typically includes processes such as fermentation, crushing, mixing, granulation, drying, cooling, screening, and packaging. By precisely controlling temperature, humidity, and ventilation conditions, the production line can accelerate the decomposition process of organic matter while killing pathogens and weed seeds, ensuring the safety and stability of the final product.

The application of innovative technology has made modern organic fertilizer production lines more efficient and environmentally friendly. From automated control systems to energy recovery devices, every link reflects the power of green technology, transforming organic waste into valuable resources.

Similarly, advancements in the NPK fertilizer production line have revolutionized precision nutrient delivery. These systems enable exact formulation of nitrogen, phosphorus, and potassium ratios to meet specific crop requirements. Complementing this, the bulk blending fertilizer line offers flexible, cost-effective solutions for creating custom blends that address diverse soil conditions.

As global attention to sustainable agriculture increases, the importance of modern fertilizer production becomes increasingly prominent. These systems not only provide effective solutions for organic waste treatment but also serve as important tools for promoting green agriculture and achieving a circular economy. Investing in advanced production technology is investing in a greener, more sustainable future.

Organic Lines

Transform waste into nutrient-rich fertilizers through eco-friendly processes

NPK Production

Precision formulation of essential nutrients for targeted crop nutrition

Bulk Blending

Custom fertilizer blends tailored to specific soil requirements