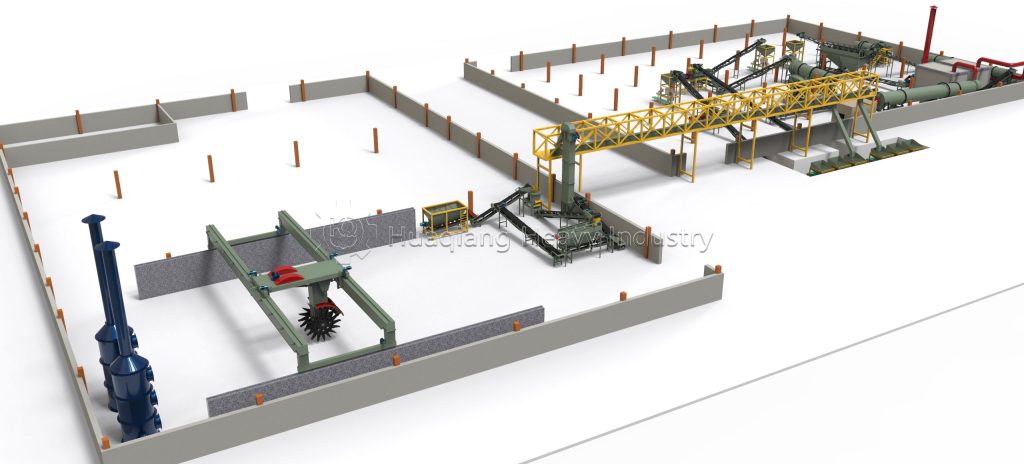

Modern organic fertilizer application begins with understanding the sophisticated processes behind its production. Within the contemporary organic fertilizer factory, the journey starts with organic fertilizer composting technology, where controlled organic fertilizer fermentation transforms raw biomass into nutrient-rich material. This carefully managed biological process is crucial for developing stable, plant-ready nutrients. The material then progresses through the complete organic fertilizer production line, where the organic fertilizer granulator shapes the finished product into uniform pellets for optimal soil application and nutrient release.

Special Compost Formulas

High-Efficiency Mushroom Compost

Formula: Sawdust 50%, bran 25%, corn meal 15%, lime 5%, gypsum 5%

Key Points: Adjust moisture to 60%, compost for 20 days with 3-4 turnings

Flower and Fruit Special Compost

Formula: Mature compost 60%, bone meal 15%, seaweed powder 10%, plant ash 10%, eggshell powder 5%

Features: Rich in phosphorus and potassium, promotes flowering and fruiting

Functional Fermented Liquid Formulas

Root-Promoting Fermented Liquid

Ingredients: Willow branches 1kg, brown sugar 0.5kg, water 5L

Preparation: Seal and ferment for 15 days, dilute 50 times before use

Disease-Resistant Fermented Liquid

Ingredients: Garlic 1kg, chili peppers 0.5kg, ginger 0.5kg, brown sugar 1kg, water 10L

Benefits: Controls pests and diseases, enhances plant resistance

Modern Improvement Solutions

Mechanized Composting Systems

Using rotary drum composters with mechanical turning and temperature control systems, reducing composting周期 to 15-20 days, significantly improving production efficiency.

Intelligent Fermentation Monitoring

Using pH sensors, temperature monitors, and automatic venting devices to precisely control fermentation process and ensure stable product quality.

Formula Optimization Software

Based on different crop needs and soil conditions, calculating optimal ingredient ratios through professional software to achieve precise fertilization.

Quality Control Standards

- Maturity Testing:C/N ratio less than 20, seed germination index greater than 80%

- Hygiene Standards:Coliform bacteria less than 1000 MPN/g, ascaris egg mortality greater than 95%

- Nutrition Standards:Organic matter content greater than 30%, heavy metal content below national standards

- Physical Indicators:Moisture content less than 30%, pH value 6.5-8.5

Future Development Trends

Organic fertilizer production is moving towards intelligent, precise, and large-scale development. Combined with IoT technology and big data analysis, future production will achieve full-process automated monitoring and personalized formula customization. Meanwhile, the development of new microbial agents will further enhance the effectiveness of organic fertilizers, providing stronger support for sustainable agricultural development.

This technological transformation begins at the organic fertilizer factory, where advanced organic fertilizer composting technology integrates with IoT sensors to optimize the crucial organic fertilizer fermentation phase. Real-time monitoring of temperature, moisture, and oxygen levels ensures ideal conditions for microbial activity, significantly improving decomposition efficiency and product quality.

Within the comprehensive organic fertilizer production line, the organic fertilizer granulator evolves into an intelligent component that automatically adjusts its operations based on formula requirements and raw material characteristics. This synergy between biological processes and mechanical precision enables manufacturers to produce customized fertilizers that address specific soil needs and crop requirements, driving the next generation of sustainable agriculture forward.