In the fields of modern chemical and fertilizer production, the disc granulator acts like a skilled sculptor, transforming powdered raw materials into uniform, plump granules through its unique rotating charm. This seemingly simple equipment contains exquisite mechanical principles and process wisdom.

Exquisite Design: A Process Masterpiece

Smart Tilt Adjustment

The disc inclination can be flexibly adjusted according to material characteristics and granulation requirements, ensuring each raw material completes the granulation process at the optimal angle for precise control.

Continuous Efficient Production

Unique intermittent continuous production method significantly reduces labor intensity and improves work efficiency, making the production process more fluid and natural.

Modular Structure

Composed of modules including disc, transmission device, and frame, featuring simple and reasonable structure, convenient maintenance, and long service life.

Magical Granulation Process: A Perfect Demonstration of Mechanics

Material Feeding

Powdered raw materials evenly enter the rotating disc through the feeding device, beginning their transformation journey

Moistening & Forming

Water spray device precisely sprays water or binder as materials begin to coalesce and form nuclei in moist conditions

Rolling Granulation

Under the combined effects of centrifugal force, friction, and gravity, materials continuously roll, compact, and form

Mature Discharge

When particle gravity exceeds centrifugal force, uniform granules are automatically discharged from the disc edge, completing granulation

Outstanding Advantages: Redefining Granulation Standards

· Energy Efficient – Lower energy consumption compared to other granulation equipment, with more competitive operating costs

· Strong Adaptability – Capable of processing various materials with different properties, wide application range

· Excellent Product Quality – Granules with good sphericity, high strength, and stable, reliable quality

· Easy Operation – High degree of automation, minimal manual intervention, easy to master

· Convenient Maintenance – Simple structure, low failure rate, minimal daily maintenance workload

Wide Applications: Ideal Choice for Multiple Industries

With its excellent performance and adaptability, the disc granulator shines in multiple fields. In the fertilizer industry, it transforms various powdered raw materials into uniform fertilizer granules; in the metallurgical field, it processes materials like mineral powders; in the chemical industry, it meets various chemical raw material granulation needs. Its gentle granulation method is particularly suitable for production scenarios requiring high particle integrity.

The disc granulator represents not only the wisdom of mechanical engineering but also an outstanding example of modern production technology. With its simple structure, efficient performance, and reliable quality, it plays an indispensable role in global industrial production. From fertilizer plants to chemical factories, from mines to metallurgical enterprises, this equipment continues to provide high-quality granular products for various industries through its unique granulation method, driving continuous progress in industrial production.

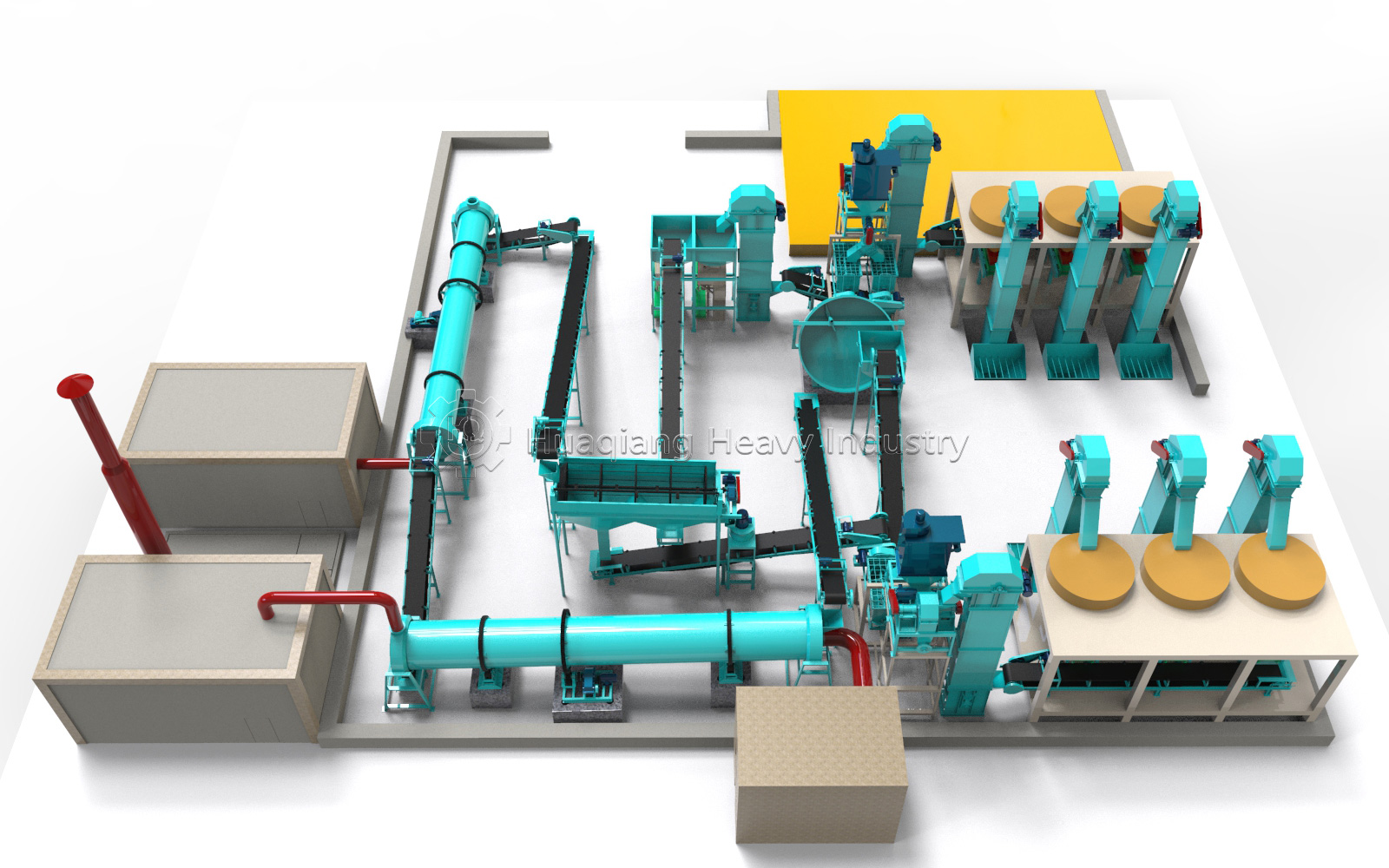

Diverse Granulation Technologies in Modern Fertilizer Manufacturing

While disc granulators excel at creating uniform spherical particles through rolling agglomeration, modern npk fertilizer production technology incorporates multiple granulation methods to suit different material requirements. Within the comprehensive npk manufacturing process, the disc granulator represents one approach among several specialized fertilizer production machine options. Alternative technologies include the rotary drum granulator for large-scale continuous production and the roller press granulator production line which employs dry fertilizer granules compaction through specialized fertilizer compaction machine systems.

This diversity in granulation technologies allows fertilizer manufacturers to select the most appropriate equipment based on raw material characteristics, production scale, and final product specifications. The disc granulator’s gentle rolling action is ideal for materials requiring spherical shaping, while drum granulators offer higher throughput for standard formulations, and roller press systems provide dry compaction solutions for moisture-sensitive materials. The integration of these different technologies within complete production lines demonstrates the sophistication of modern fertilizer manufacturing, where equipment selection is carefully matched to specific process requirements to optimize efficiency, product quality, and operational flexibility across various fertilizer types and production scenarios.