Scientific Maintenance Extends Lifespan, Meticulous Management Ensures Efficiency

In the organic fertilizer production process, the dryer is one of the key pieces of equipment determining the final moisture content, particle stability, and overall production capacity of the product. Operating under harsh conditions of high temperature, high humidity, and high dust levels for extended periods, scientific maintenance is not only fundamental to ensuring stable equipment operation but also a core management element for reducing failure rates, extending service life, and controlling production costs. With decades of industry experience and technological accumulation, Huaqiang Heavy Industry has developed a systematic dryer maintenance management system to help customers achieve efficient and economical operation throughout the entire equipment lifecycle.

Daily Inspection: Building the First Line of Defense for Preventive Maintenance

Effective maintenance begins with standardized daily inspections. Operators should complete the following key checks before starting the machine each day:

Cylinder and Liner Inspection: Observe the wear condition of the wear-resistant lining plates (usually lifting plates or special linings) on the inner wall of the drying drum. When the wear thickness at a single point exceeds 3 mm, replacement should be planned immediately. Otherwise, wet material is prone to sticking and accumulating on the bare plate, severely reducing heat exchange efficiency and potentially causing uneven heating of the cylinder.

Ventilation and Screen Inspection: Clean the screens and grids at the inlet and outlet to ensure no debris such as woven bag fragments, stones, or tangled fibers block the flow. Unobstructed ventilation paths are crucial for timely removal of evaporated moisture and maintaining the circulation of the drying medium.

Transmission System Lubrication: Check the oil level sight glasses of the main drive gear and support roller bearing housings to ensure the lubricating oil level is within the standard range. Use the specified type of high-temperature anti-wear lubricating oil and replenish it weekly to form an effective oil film in high-temperature environments, reducing gear meshing wear and bearing loss.

Regular Maintenance: The Core of Systematic Deep Maintenance

Based on daily inspections, a periodic deep maintenance plan must be established and strictly implemented.

Monthly Maintenance: Use an infrared thermometer to focus on checking the operating temperature of each support bearing and transmission bearing. If the bearing surface temperature consistently exceeds 80℃, the machine must be stopped immediately for inspection. Check for insufficient lubrication, bearing damage, or misalignment during installation to prevent bearing sintering due to overheating, which could lead to a major shutdown.

Quarterly Maintenance: After shutdown, thoroughly clean the inside of the dryer drum. During long-term operation, dust and low-melting-point semi-coke deposits will accumulate on the drum wall, forming a heat insulation layer. High-pressure water jet flushing combined with mechanical scraping should be used to remove the scale, restoring the heat transfer efficiency of the drum’s metal surface. This can significantly reduce fuel consumption.

Annual Overhaul: A comprehensive shutdown overhaul should be scheduled annually. Key points include: replacing all aging seals (such as kiln head and kiln tail seals) to prevent air and material leaks; inspecting and replacing worn conveyor belts or chain plates; calibrating temperature sensors, pressure sensors, and other monitoring instruments using standard instruments to ensure the accuracy of process parameter data acquisition and provide reliable data for automatic control.

III. Professional Support and Intelligent Upgrade: Advanced Maintenance System Guarantee

In addition to independent maintenance, leveraging the professional services of equipment suppliers can effectively improve maintenance levels. For example, Huaqiang Heavy Industry’s full lifecycle after-sales maintenance solution for its Ukrainian customers includes not only regular on-site inspections and fault diagnosis, but also optimization suggestions for drying process parameters based on local fuel characteristics and raw material moisture fluctuations. This service extends the trouble-free operating life of the customer’s dryer to over 8 years and reduces annual comprehensive maintenance costs by approximately 40%.

Furthermore, the introduction of predictive maintenance technology is the future direction. By installing vibration sensors and online oil monitoring devices in key areas and connecting to an IoT platform, real-time monitoring and big data analysis of equipment operating status can be achieved, providing early warnings of potential faults and upgrading the maintenance model from “regular prevention” to “precise prediction.”

Conclusion: Maintenance Creates Value Dryer maintenance is not simply “repairing when it breaks down,” but a systematic project spanning the entire service life of the equipment. It requires companies to establish standardized processes from daily inspections, weekly maintenance, monthly upkeep to annual repairs, and cultivate employees’ habits of standardized execution. Scientific maintenance management directly translates into less unplanned downtime, lower energy and material consumption, longer equipment service life, and more stable product quality. For organic fertilizer production enterprises, investing in the meticulous maintenance of equipment is investing in the core competitiveness and sustainable profitability of the production line.

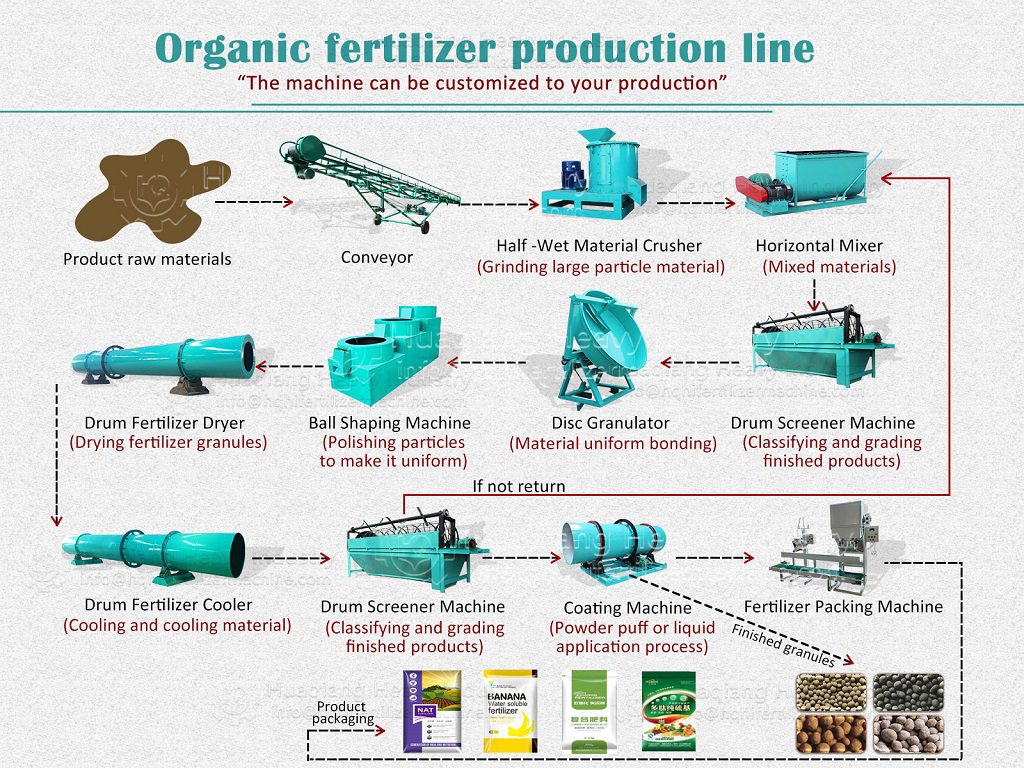

Integrated Production: From Fermentation to Finished Granules

The well-maintained dryer is a critical component within a complete organic fertilizer manufacturing system. Its role is to process material from the preceding organic fertilizer fermentation process, which is often accelerated by equipment like a chain compost turning machine. Following drying, the core stage of organic fertilizer production granulation shapes the material into a marketable product. Several granulation technologies are available within an organic fertilizer production line. A traditional method is the organic fertilizer disc granulation production line, which forms spherical pellets. For higher capacity, a rotary drum granulator may be used.

The choice of granulator is diverse. For cylindrical pellets, a flat die pelleting machine is effective. For space and process efficiency, a new type two in one organic fertilizer granulator (or a new type organic fertilizer granulator) combines mixing and granulation. More complex setups, like an organic fertilizer combined granulation production line, integrate multiple methods. When the process incorporates specific microbial consortia, it becomes a specialized bio organic fertilizer production line. Ultimately, this integrated approach defines modern organic fertilizer manufacturing, transforming raw organic waste into a standardized, nutrient-rich agricultural input.

Therefore, each piece of equipment, from the compost turner to the dryer and the granulator, is a vital link in a synchronized chain. Professional maintenance of each unit ensures the reliability and efficiency of the entire system, maximizing the return on investment in organic fertilizer production.