With the continued growth in demand for organic fertilizer, many small-scale organic fertilizer production enterprises already in operation face an urgent need to increase their production capacity. How to stably increase capacity from 1 ton/hour to 3 tons/hour without large-scale modifications has become a key issue for enterprise development. This article provides a systematic and practical solution based on several successful upgrade cases.

Bottleneck Diagnosis: Identifying Key Aspects of Capacity Limitations

Before developing an upgrade plan, a comprehensive assessment of the existing production line is essential:

Fermentation Bottlenecks:

Insufficient turning frequency leads to excessively long fermentation cycles.

Fermentation tank volume limitations prevent processing of increased raw materials.

Inefficient aeration system affects microbial activity.

Pre-treatment Issues:

Insufficient crushing equipment capacity becomes a production bottleneck.

Inadequate mixing uniformity affects subsequent granulation efficiency.

Granulation and Post-processing Limitations:

Upper capacity limit of the granulator design.

Insufficient heat exchange efficiency of the drying and cooling system.

Mismatched processing capacity of screening equipment.

System Upgrade: A Three-Step Capacity Improvement Plan

Phase 1: Process Optimization and Equipment Fine-tuning (Upgrading to 1.5t/h)

Fermentation Process Improvements:

Optimized turning strategy: Adopting continuous turning in three shifts shortens the fermentation cycle from 20 days to 15 days.

Adding high-efficiency microbial agents: Selecting compound fermentation strains reduces heating time by 3… 0%

Install Automatic Temperature Monitoring System: Real-time monitoring of temperature changes for precise control of the fermentation process.

Pre-treatment Upgrade:

Add pre-crushing equipment before the existing crusher to form a two-stage crushing system.

Modify the mixer blades to increase mixing efficiency by 20%.

Install an online moisture meter for precise control of raw material moisture content.

Second Stage: Key Equipment Upgrade (Upgrade to 2.2t/h)

Pelletizing System Modification:

Replace the pelletizing disc with a larger diameter disc (upgrade from Φ2.2m to Φ3.0m).

Optimize the pelletizing disc tilt adjustment mechanism for rapid and precise adjustment.

Install an automatic liquid spraying system to ensure uniform addition of binder.

Drying System Upgrade:

Increase the density of the lifting plates inside the dryer to improve heat exchange efficiency.

Optimize the hot air system to increase hot air circulation utilization.

Install a waste heat recovery device to reduce energy costs.

Third Stage: Automation and System Integration (Achieving 3t/h)

Automation Control System Construction:

Install a PLC centralized control system. Achieve inter-equipment linkage:

Establish a production data monitoring platform to optimize process parameters in real time.

Configure an intelligent alarm system to reduce downtime due to malfunctions.

Logistics system optimization:

Upgrade the raw material conveying system by adopting frequency converter-controlled belt conveyors.

Add an automatic finished product packaging line, increasing packaging efficiency by 50%.

Optimize the workshop logistics layout to reduce material transfer time.

III. Economic Benefits:

Capacity increase: From 1 t/h to 3 t/h, annual capacity from 2400 tons to 7200 tons (based on 300 operating days per year).

Cost reduction: Unit product energy consumption reduced by 25%, labor costs reduced by 40%.

Investment payback period: Generally 6-10 months. Recoverable Investment

Implementation Key Points and Precautions

Gradual Approach:Avoid large-scale, one-time upgrades. Complete the first phase of verification before proceeding to subsequent phases.

Equipment Compatibility:Newly purchased equipment must be highly compatible with existing systems. Customized design may be necessary.

Personnel Training:Systematic training should be provided to operators after each upgrade phase.

Quality Control:A stricter quality control system must be established during capacity expansion.

Environmental Compliance:Environmental protection facilities must be reassessed after capacity expansion to ensure emissions meet standards.

Successful Case Study

A Shandong organic fertilizer company adopted this solution and completed its capacity upgrade in 6 months:

Phase 1: Through process optimization, capacity increased to 1.5 t/h within one month.

Phase 2: After upgrading key equipment, capacity reached 2.3 t/h.

Phase 3: After automation upgrades, stable capacity reached 3.1 t/h. The company’s annual profit increased by 1.5 million yuan after the upgrade, with a payback period of only 7 months.

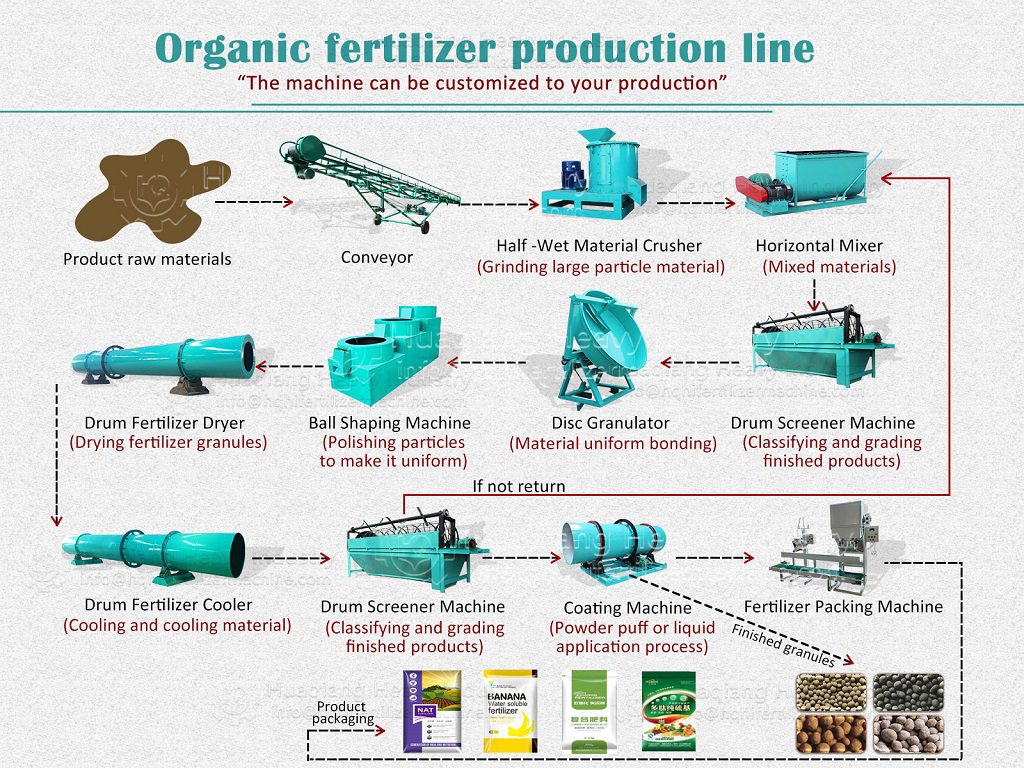

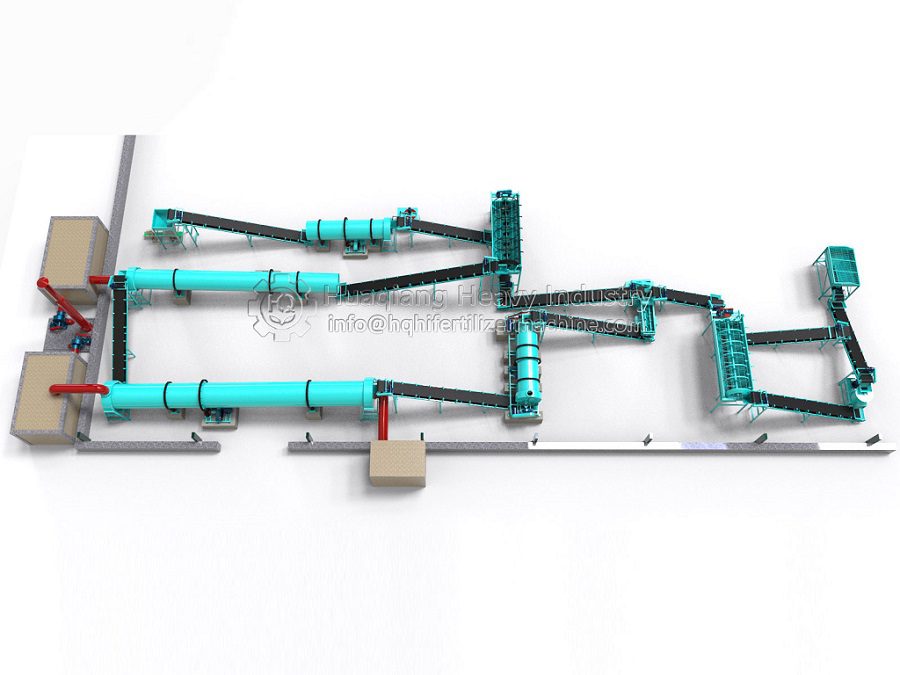

Strategic Upgrades within the Organic Fertilizer Production System

The capacity expansion strategy highlights the interconnected nature of a complete organic fertilizer manufacturing system. Increasing throughput often requires parallel upgrades across the entire organic fertilizer production line. For instance, to support a higher-capacity granulation stage, the upstream organic fertilizer fermentation process must be accelerated, which may involve upgrading to a more efficient chain compost turning machine for faster and more uniform decomposition. This ensures a sufficient supply of high-quality compost feedstock for the increased granulation demand.

The core stage of organic fertilizer production granulation is often a primary bottleneck. The upgrade plan might involve replacing a standard organic fertilizer disc granulation machine with a larger model or transitioning to a higher-capacity organic fertilizer disc granulation production line. Alternatively, to save space and process steps, a new type two in one organic fertilizer granulator that combines mixing and granulation could be an efficient upgrade path. If the goal is to produce a microbial-enhanced product, the entire line may evolve into a specialized bio organic fertilizer production line. These strategic equipment changes are central to modernizing organic fertilizer manufacturing for greater scale and profitability.

Therefore, successful capacity expansion is not about upgrading a single machine in isolation. It requires a holistic view of the entire system—from composting and crushing to mixing, granulation, and drying—ensuring that each upgraded component is synchronized to achieve the new, higher production target efficiently and reliably.

Capacity expansion of small-scale organic fertilizer production lines is a systematic project requiring coordinated efforts in process optimization, equipment upgrades, and management improvement. Enterprises should develop detailed, phased implementation plans based on their own specific circumstances, steadily increasing production capacity while ensuring product quality. Through scientific upgrading and transformation, not only can production capacity be significantly improved, but production costs can also be substantially reduced, enhancing market competitiveness and laying a solid foundation for the enterprise’s sustainable development.