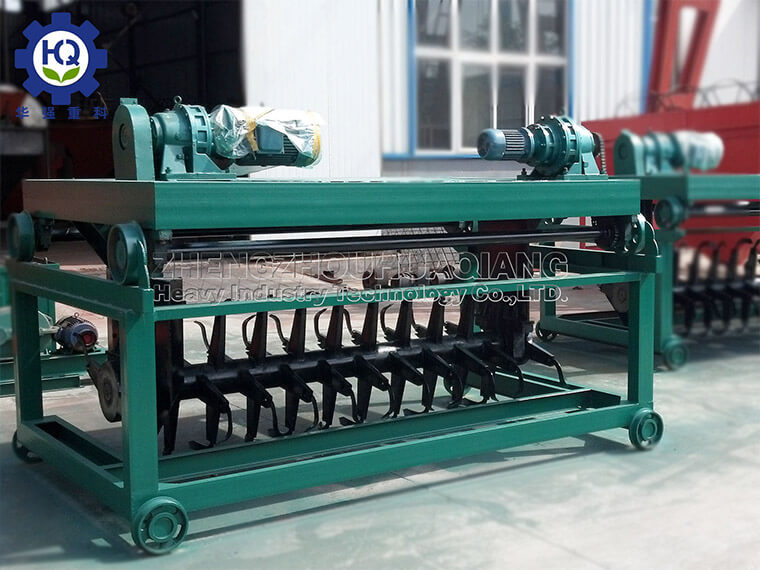

Organic fertilizer turning machine ferments organic fertilizer to solve pollution in chicken farms

The organic fertilizer turning machine plays a key role in the process of treating chicken manure and other organic waste in chicken farms, effectively solving multiple environmental challenges faced by chicken farms, manifested in the following aspects:

1. Reduce the release of ammonia and odors

If chicken manure in chicken farms is not treated in a timely manner, it will release a large amount of harmful gases such as ammonia and hydrogen sulfide, causing serious air quality problems. The organic fertilizer turning machine accelerates the oxidation and decomposition of chicken manure through mechanical turning and ventilation, effectively reducing the production of odorous gases such as ammonia and improving the surrounding environment.

2. Control pathogens and pests

Untreated chicken manure often contains pathogenic bacteria, viruses, and parasite eggs, which pose a threat to public health if directly discharged into the environment. Through the high-temperature fermentation process of the organic fertilizer turning machine, these pathogens can be efficiently inactivated to ensure the safety of the surrounding environment.

3. Reduce water loss

Chicken manure usually has a high water content, and improper treatment can cause sewage to cross flow and pollute water sources. The organic fertilizer turning machine adjusts the material humidity to promote water evaporation, avoid excessive water loss, and reduce the pressure of subsequent processing.

4. Turning waste into treasure

Chicken manure, which was originally considered waste, is processed into organic fertilizer by an organic fertilizer turning machine and can be supplied to farmland. This not only reduces the cost of waste disposal in chicken farms, but also creates additional economic value and achieves resource recycling.

5. Improve soil structure

The organic fertilizer prepared by the organic fertilizer turning mechanism is rich in organic matter, which can effectively improve soil structure, enhance soil water and fertilizer retention capacity, increase soil microbial activity, and in the long run, have a positive effect on promoting crop growth and improving crop quality.

6. Reduce greenhouse gas emissions

Compared to synthetic fertilizers, the use of organic fertilizers can reduce greenhouse gases such as carbon dioxide produced by the fertilizer industry, slowing down the pace of climate change from the source and aligning with environmental trends.

Therefore, the organic fertilizer turning machine is not only an effective tool for chicken farms to address pollution issues, but also an important link in promoting sustainable agricultural development and building an ecological circular economy model. Through scientific management and technological innovation, chicken farms can achieve a win-win situation of environmental protection and economic benefits.