Breaking terrain limitations to deliver efficient composting solutions in the most challenging environments

A Revolution in Terrain Adaptability

In the field of organic waste treatment, crawler compost turners have redefined the possibilities as a versatile compost fertilizer machine with their exceptional terrain adaptability. Compared to traditional wheeled equipment, this innovative design liberates composting operations from site constraints, making it an essential component among the equipments required for biofertilizer production.

Whether on soft mud, rugged uneven ground, or slippery slopes, crawler turners move with confidence and stability, ensuring consistent bio organic fertilizer production regardless of environmental conditions. This robust fertilizer production machine maintains operational efficiency across challenging landscapes, enabling continuous processing of organic materials into valuable nutrients.

The crawler system represents a significant advancement in composting technology, providing reliable performance that supports scalable bio organic fertilizer production operations while overcoming the limitations that traditionally hindered organic waste processing in difficult terrain.

The true advantage of crawler design lies in its excellent ground pressure distribution and powerful traction. The wide track plates evenly distribute equipment weight, effectively preventing sinking in soft ground. This design not only ensures mobility in various complex terrains but also provides reliable support for continuous, efficient composting operations, making organic waste treatment independent of weather and site conditions.

Core Components of Precision Engineering

The outstanding performance of windrow compost turner stems from six carefully designed core systems. Each system is optimally configured, collectively forming the strong competitiveness of this terrain-adaptive composting equipment.

Crawler Travel Mechanism

Includes tracks, drive wheels, and guide wheels, providing powerful ground grip and stability for various complex terrain conditions

Turning and Mixing Mechanism

Equipped with mixing arms, blades, or spiral devices that penetrate compost materials for efficient turning and increased oxygen supply to promote fermentation

Hydraulic Power System

Provides strong power for turning and travel mechanisms, enabling precise control of turning depth, speed, and movement

Intelligent Control System

Utilizes electronic control systems to automate equipment functions including turning, travel, and speed adjustment

Safety Protection System

Features multiple safety devices including overload protection and emergency stop functions to ensure safety of equipment and operators

Oxygen Supply System

Optional blower or piping system provides adequate oxygen to compost materials, promoting microbial activity and accelerating fermentation

The unique value of large wheel compost turner technology lies in its perfect integration of industrial-grade reliability with agricultural environment requirements. In large farms, organic fertilizer production bases, and agricultural waste treatment centers, this equipment demonstrates through outstanding performance that efficient composting is no longer challenging, regardless of terrain complexity.

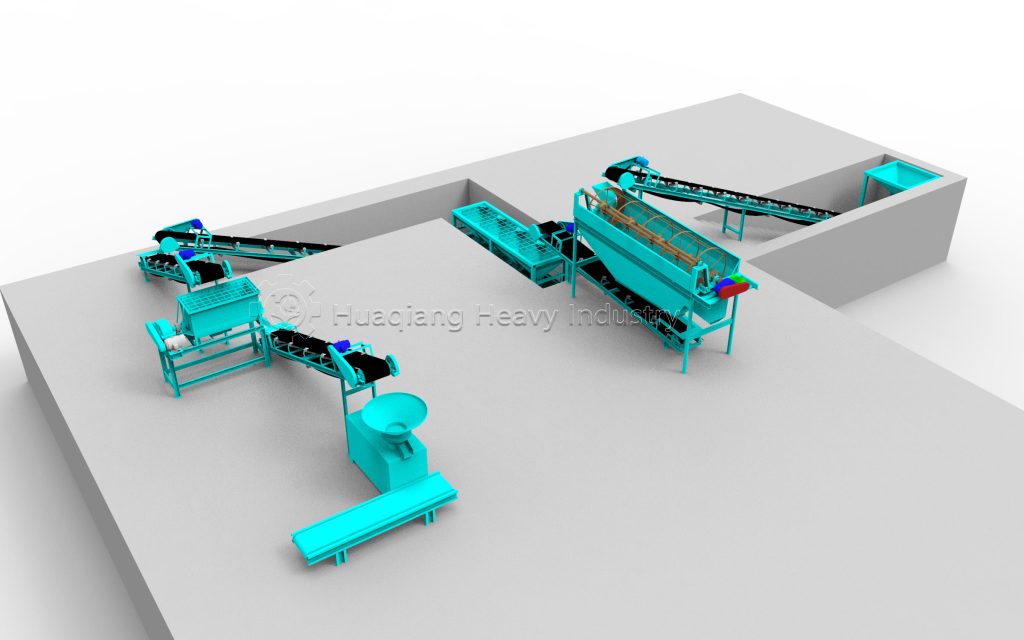

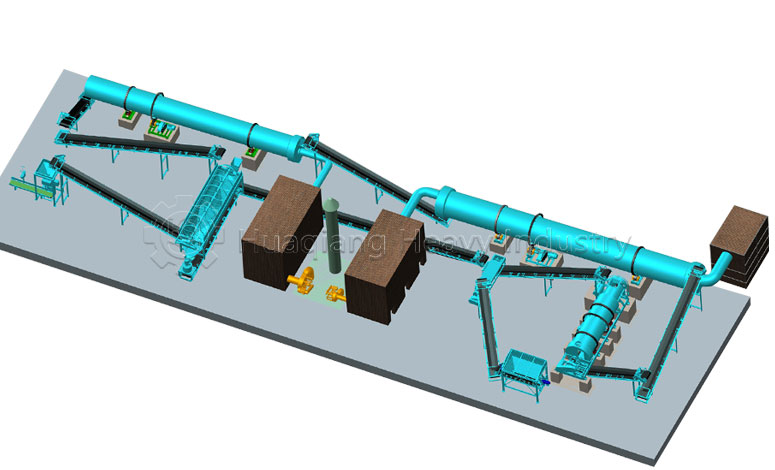

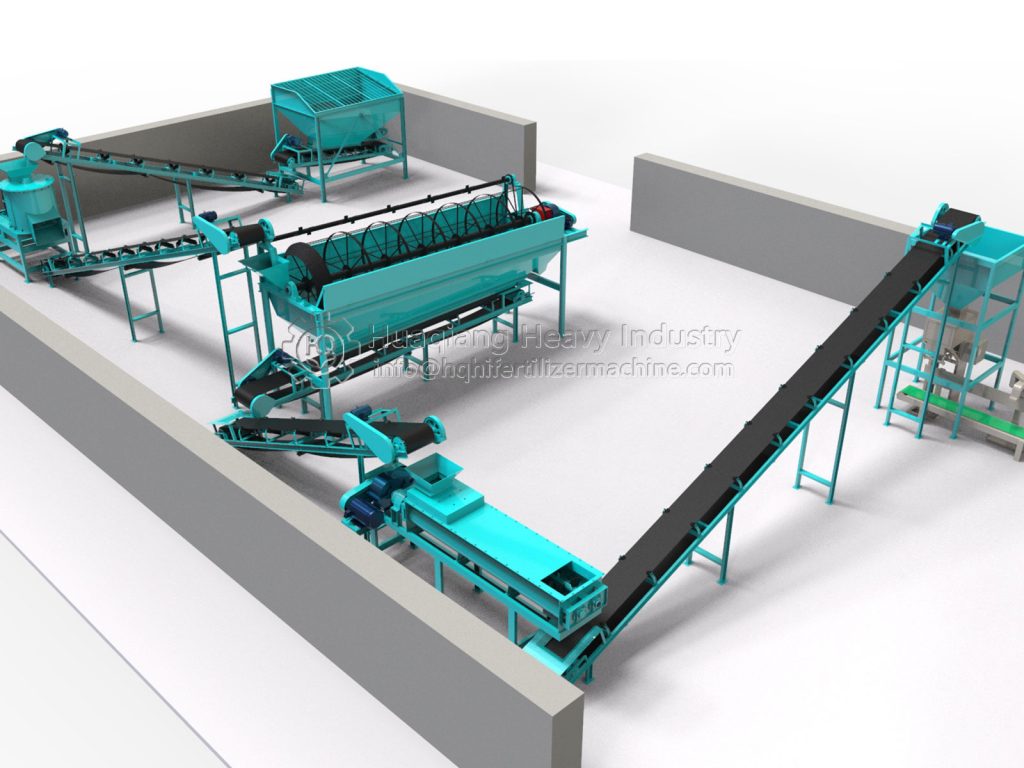

These robust machines serve as the foundation of any modern organic fertilizer production line, seamlessly connecting with subsequent processing stages. The prepared compost becomes valuable input for various granulation systems, including advanced disc granulation production line setups and efficient drum granulation equipment.

Furthermore, the organic base produced through this method can be integrated into comprehensive npk fertilizer production process systems. When combined with chemical nutrients, it creates balanced fertilizers through a complete npk production line, demonstrating the crucial role of composting technology in both organic and conventional fertilizer manufacturing.

Application Prospects and Value

As modern agriculture places increasing importance on sustainable development and resource recycling, the significance of windrow compost turner becomes more prominent. They not only solve the challenges traditional composting equipment faces in complex terrain but also open new possibilities for resource utilization of organic waste. From livestock manure treatment to crop straw utilization, from food waste conversion to organic fertilizer production, this “all-terrain warrior” is making important contributions to green agriculture and circular economy development.

Crawler Compost Turner – Breaking terrain limitations to make efficient composting achievable on any site