Behind the rapid development of the palm oil industry lies an environmental challenge: how to handle the massive amounts of empty fruit bunch waste. However, with the deepening of sustainable development concepts, these former “waste materials” are being transformed into valuable resources, opening a new path of circular economy for palm oil cultivation.

From Harvest to Waste: The Generation of Empty Fruit Bunches

The palm fruit harvesting process involves separating the fruits from the main bunch stalk. In small-scale plantations, workers use machetes to manually remove the fruits, while large plantations commonly use mechanical stripping equipment. These devices efficiently separate fruits from the main stalk through roller rubbing or blade scraping, while simultaneously screening out empty fruit bunches (EFB). Statistics show that for every ton of fresh palm fruit bunches processed, 0.2-0.3 tons of empty fruit bunches are generated, making EFB a massive by-product in the palm oil industry.

Composition Characteristics of Empty Fruit Bunches

Empty fruit bunches mainly consist of plant fiber materials, with cellulose accounting for 30%-35%, hemicellulose 25%-30%, and lignin 20%-25%, along with small amounts of ash and moisture. This composition makes it an ideal raw material for organic fertilizer. Particularly noteworthy is that oil palm trees require large amounts of potassium during growth and fruiting, therefore their leaves and fruit bunches are naturally rich in potassium, providing unique advantages for the fertilizer conversion of empty fruit bunches.

Converting empty fruit bunches into organic fertilizer not only solves the waste disposal problem but, more importantly, achieves nutrient recycling. The potassium-rich EFB compost returned to plantations can effectively improve soil structure and provide essential nutrients for oil palm trees, forming a beneficial ecological cycle.

Environmental Challenges and Sustainable Solutions

The palm oil industry faces serious environmental challenges, including tropical rainforest deforestation, biodiversity loss, and environmental pollution during processing. Traditional EFB disposal methods often involve open burning or random dumping, which not only wastes resources but also creates new environmental problems. By converting empty fruit bunches into organic fertilizer, plantations can reduce dependence on chemical fertilizers, lower environmental pollution, and simultaneously improve soil health.

Future Prospects for Circular Agriculture

The fertilizer utilization of empty fruit bunches represents an advanced concept of agricultural circular economy. This model not only addresses waste disposal issues but also creates additional economic value. With technological advancements, comprehensive utilization pathways for empty fruit bunches continue to expand, including high-value applications such as biomass energy and papermaking raw materials. This “turning waste into treasure” approach provides important insights for the sustainable development of the global palm oil industry.

In today’s global pursuit of sustainable development, the resource utilization of empty fruit bunches demonstrates an important principle: in nature, there is no real waste, only misplaced resources. Through innovative thinking and technological applications, we can transform environmental challenges into development opportunities, achieving a win-win situation for both economic benefits and ecological protection.

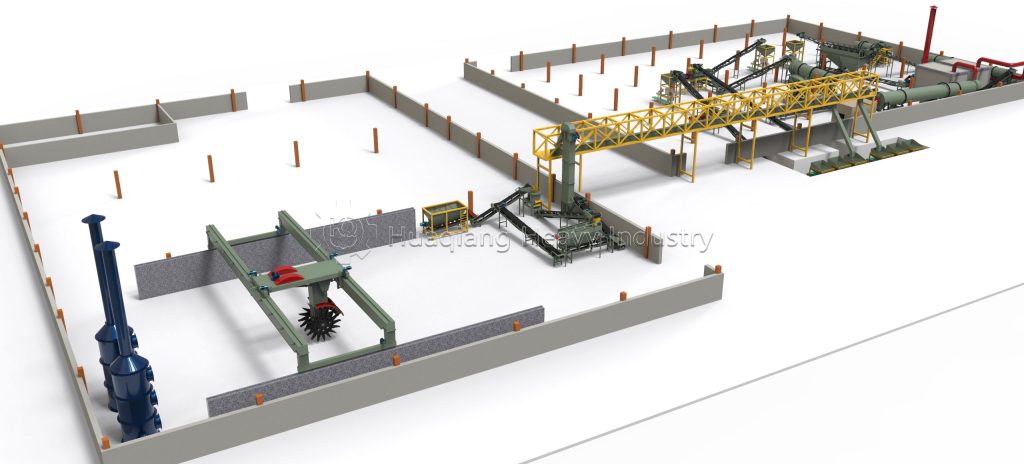

The transformation of Oil palm empty fruit bunch (OPEFB) into valuable organic fertilizer represents a perfect synergy between waste management and agricultural innovation. Modern processing facilities utilize specialized equipment like the chain compost turner and large wheel compost turning machine to efficiently manage the crucial organic fertilizer fermentation stage. The complete organic fertilizer production line incorporates advanced granulation technology, featuring equipment such as the rotary drum granulator, double roller press granulator, and specialized organic fertilizer granulator systems for optimal drum granulation. For operations requiring alternative approaches, the fertilizer roller press machine and double roller granulator offer efficient compaction solutions. This sustainable model complements traditional npk fertilizer production line operations while providing an ecological alternative to conventional npk production process methods. The integration of these technologies into a comprehensive bio organic fertilizer production line demonstrates how agricultural waste can be transformed into premium fertilizers. As the industry evolves, the combination of efficient wheel compost turner systems and advanced fertilizer granulator technology creates a circular economy model that benefits both palm oil producers and the environment, setting new standards for sustainable agricultural practices worldwide.