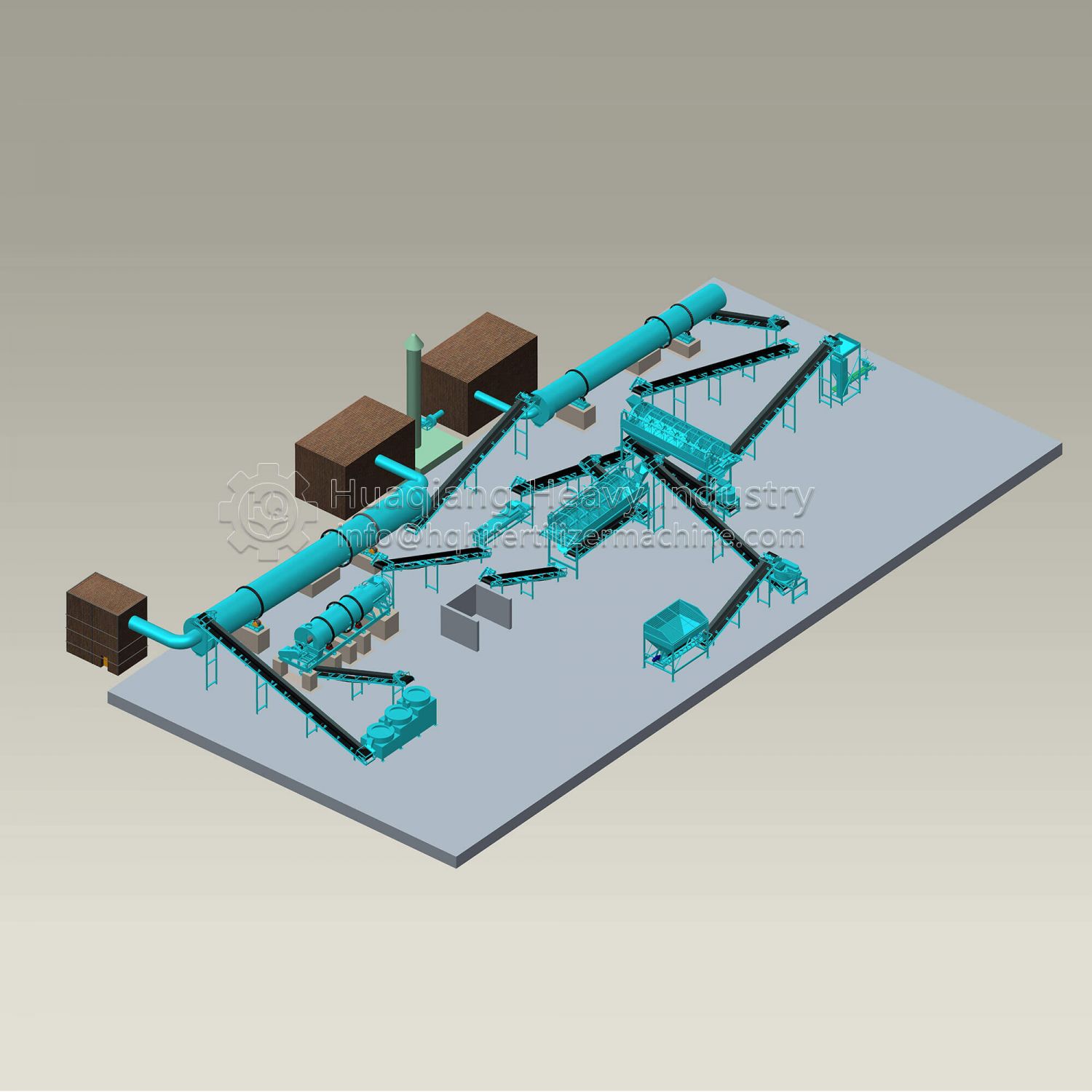

The complete set of organic fertilizer equipment needs fermentation and turning machine, organic fertilizer grinder, drum screening machine, horizontal mixer, fertilizer granulator, rotary dryer, cooler, screening machine, coating machine, packaging machine, conveyor and other equipment.

Fermentation is the first step of pig manure organic fertilizer production. Composting fermentation is widely used in organic fertilizer production. So what are the complete steps of pig manure fermentation?

Treatment requirements of

compost turning machine

1. Temperature requirements. The start-up temperature should be above 15 ℃ (it can be operated in four seasons and not affected by seasons. Fermentation should be conducted indoors or in Greenhouse in winter).

2. Materials are piled up. When doing heap, it should not be too small or too short. If it is too small, fermentation will be affected. The height is 1. The results showed that the fermentation effect was better when the length was more than 2-4 meters and 5-2 meters. Many organic fertilizer plants use fermentation tank for fermentation. The tipper can move flexibly on the track, with large treatment capacity and high efficiency.

3. Turn over the pile for ventilation. During the fermentation process, proper oxygen supply and composting should be paid attention to (overturn several times when the temperature rises to 75 ℃) and the temperature should be controlled at about 65 ℃. If the temperature is too high, the nutrients will be affected.

4. Fermentation is complete. Generally, the fermentation can be completed within a week, the material is dark brown, and the temperature begins to drop to room temperature, indicating that the fermentation is complete. If there are too many auxiliary materials such as sawdust, wood chips, and rice husks, the fermentation time should be prolonged until fully decomposed. After being decomposed, it is further processed by

rotary drum granulator.

5. Material ratio. 1.5 tons of pig manure (about 2.5 tons of fresh manure) plus 1 kg of fertilizer starter, the starter must be mixed with rice bran (or bran, corn flour and other substitutes) in a ratio of 1:5, and then evenly sprinkled Put it into the pig manure pile and mix evenly.