The Process Characteristics of Organic Fertilizer Fermentation and Piling Machine for Cow and Sheep Manure

If you want to raise chickens, you need to be environmentally friendly. What should you do with chicken manure in a chicken farm? Where should we go? The slot type tipping machine can use a transfer truck to perform multiple slot operations in one machine. High yield, small land area for flipping, material flipping, and reduced moisture during the fermentation process, stable equipment operation, and extremely low failure rate, making it an ideal equipment for chicken manure fermentation treatment in chicken farms.

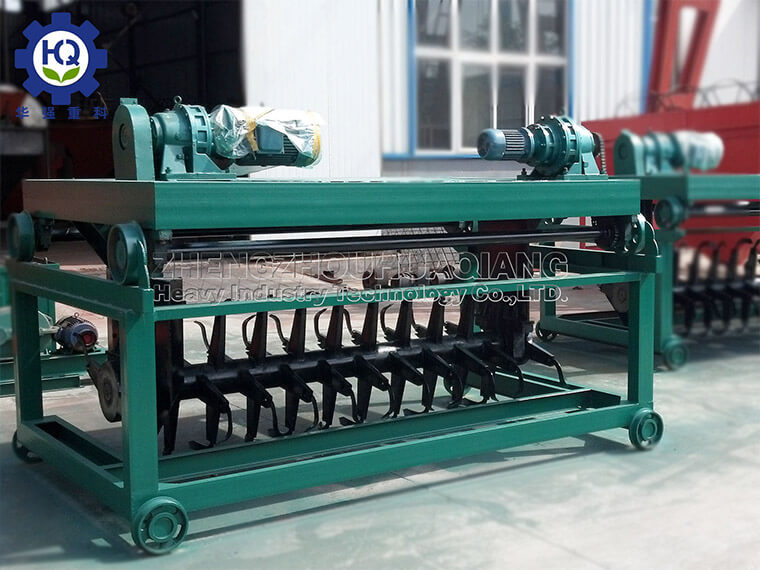

The cow and sheep manure organic fertilizer fermentation and tipping machine is commonly referred to as a guide rail type tipping machine. It can be used for fermentation and composting of organic waste such as livestock and poultry manure, sludge waste, sugar factory filter mud, residue cake, and straw sawdust. It is widely used for fermentation and moisture removal operations in organic fertilizer plants, compound fertilizer plants, sludge waste plants, horticultural fields, and mushroom cultivation plants.

1. High efficiency, stable operation, sturdy and durable, even flipping and throwing. The control cabinet is centrally controlled and can achieve manual or automatic control functions. The process of treating chicken manure and urine is also the process of fermenting bacteria to ripen, and the overturning and stirring of the 4-meter trough compost flipper in the chicken farm can not only increase air circulation, but also achieve rapid decomposition, dehydration, and fertilization of chicken manure and urine.

2. The tooth extraction is sturdy and durable, and the stacking material has certain crushing and mixing functions. The use of ectopic fermentation by the 4-meter trough compost flipper in the chicken farm can not only effectively save the land resources occupied by breeding, but also achieve reasonable utilization of land resources by expanding the scale of the chicken farm!

3. The fermentation tank of the slot type tipping machine is a reinforced concrete structure, and two adjacent fermentation tanks share the same tank wall. The width of the pool wall is determined according to the requirements of the throwing machine. The pool wall should be able to withstand the pressure of the tipping machine, and the bottom plate of the fermentation tank should not only bear the gravity of the fermentation material but also the gravity of the loader, while also meeting the requirements of ventilation.

.jpg)