Process flow and equipment configuration of chicken manure organic fertilizer production line

The fermented feces of livestock and poultry in rural areas, such as chicken manure and pig manure, have a significant impact on crop growth, effectively reducing pests and insect eggs, and improving soil compaction. They are widely used as organic fertilizers. Not only chicken manure, but also various types of livestock and poultry, including human manure, contain a large amount of bacteria, insect eggs, and parasites. Uncooked manure cannot be directly applied to crops. Using the chicken manure organic fertilizer production line to ferment and produce organic fertilizer, making chicken manure more valuable and enhancing the interests of merchants..jpg)

The production process of chicken manure organic fertilizer processing equipment:

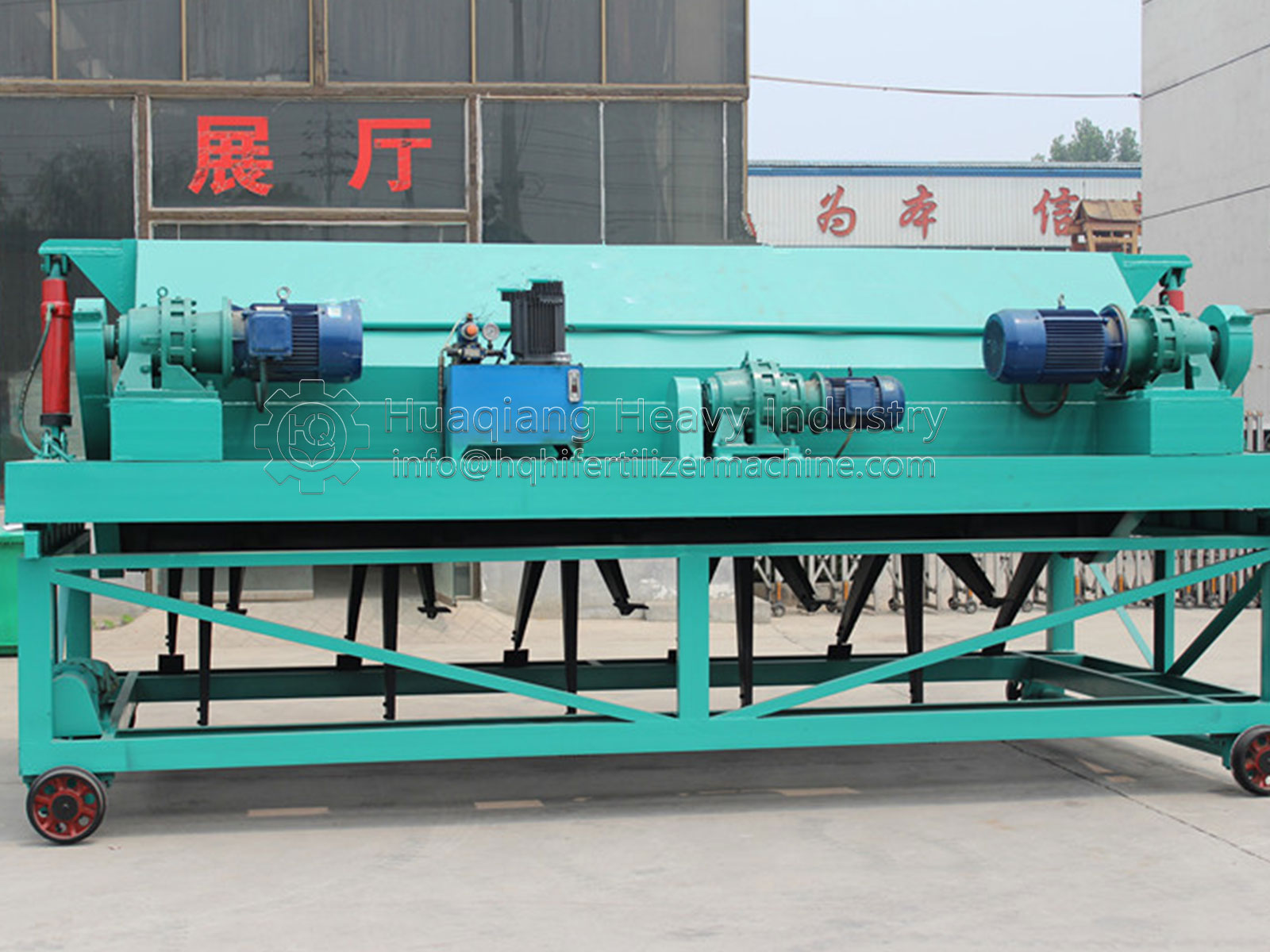

1. Raw material fermentation, using a fermentation tipping machine to flip and toss the raw materials during the fermentation process irregularly.

2. Use a forklift to shovel the fermented raw materials into the silo, where they are transported by a belt conveyor to a semi wet material crusher for crushing.

3. The crushed material is transported to the organic fertilizer horizontal mixer through a belt conveyor, and the auxiliary materials are fed into the horizontal mixer through another belt conveyor. The raw materials and auxiliary materials are uniformly fused and then transported to the granulator through a belt conveyor.

4. The organic fertilizer granulator converts the raw materials into granules and then sends them to a drum dryer through a belt conveyor. After drying, the materials are sent to a cooling machine through a belt conveyor for cooling.

5. The cooled particles are fed into the screening equipment through a belt conveyor, which has three discharge ports: small particles, qualified particles, and large particles. Small particles are returned to the granulation process through a belt conveyor, while large particles are fed into the crushing process through a belt conveyor. Qualified particles are fed into the organic fertilizer automatic packaging machine through a belt conveyor and packaged into bags.

The low configuration of animal manure organic fertilizer equipment only requires a grinder, mixer, granulator, screening machine, and packaging machine to complete production. This is a basic configuration, and equipment can be added according to the actual needs of customers. Therefore, the prices of the entire set of organic fertilizer processing equipment range from tens of thousands to hundreds of thousands. Users are considering making granular organic fertilizers and powdered organic fertilizers, and can choose appropriate equipment configurations based on their own investment situation.

.jpg)