Performance characteristics of organic fertilizer granulator: for organic fertilizer raw materials, livestock manure and urine, compost fertilizer, green fertilizer, sea fertilizer, cake fertilizer, peat, soil and miscellaneous fertilizer, microorganism and other urban domestic garbage The new organic fertilizer granulator has the specificity of organic fermentation fertilizer granulation, and the particles are pellets. The machine is suitable for a variety of different formulations. The compressive strength of organic fertilizer is higher than that of disc and drum, and the large ball rate is lower than 15%. The particle size uniformity can be adjusted through stepless speed regulation function according to user requirements. This machine is suitable for direct granulation of organic fertilizer after fermentation to reduce manufacturing costs.

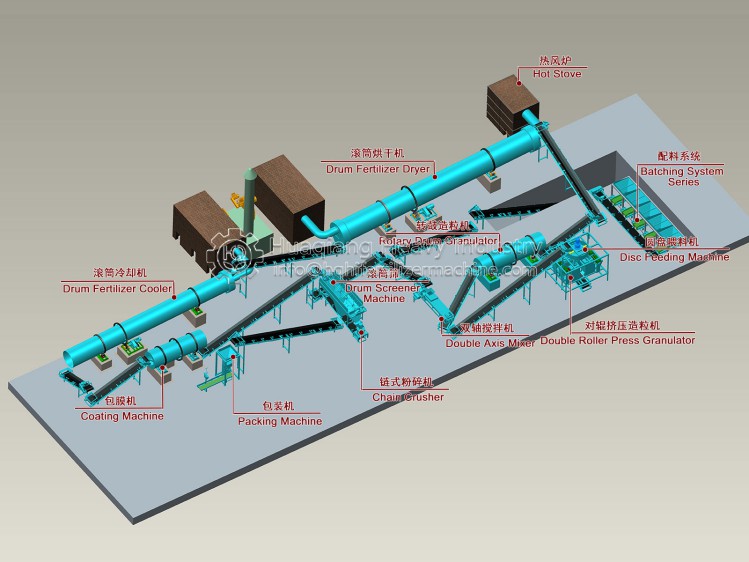

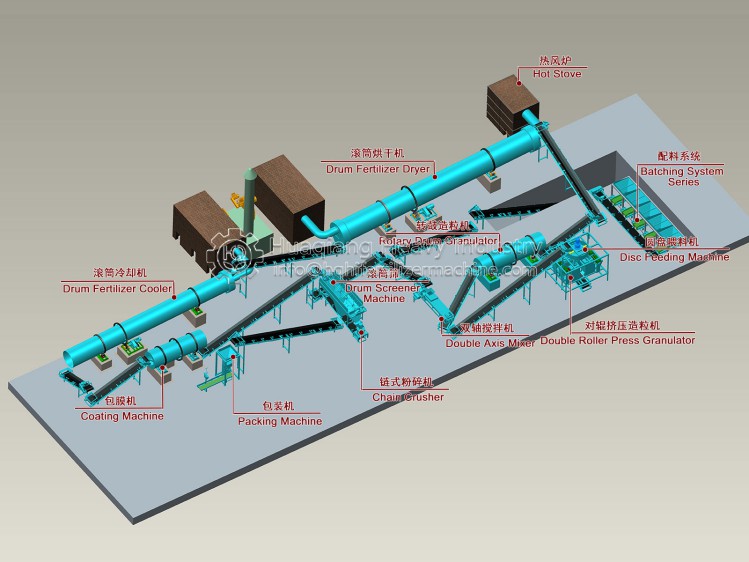

The process flow of the powdery organic fertilizer production line is as follows:

1. First, mix chicken dung with proper amount of straw powder. The amount depends on the water content of chicken dung. Generally, 45% water content is required for fermentation. That is to say, knead it into a ball, see water in the fingers, but do not drip, and release it to dissolve

2. Then add the prepared mixture into the mixer for mixing. The mixing must be uniform, transparent and free of raw blocks

3. The raw materials are fed into the fermentation tank to add the fermentation bacteria. The fermentation tank is built into a 2.5 m wide and 0.8 m-1 m high strip, which is flipped once every 2 days (the length, width and height of the fermentation tank can be determined according to the actual site). The fermentation of bacteria used here is mainly for rapid temperature rise, fermentation, deodorization, and elimination of harmful bacteria. The fermentation tank is stacked for 2 days of temperature rise, 4 days of odorlessness, 7 days of looseness, and 9 days of fragrance Fertilization in 10 days. Specifically, the temperature on the second day of composting can reach 60 ℃ – 80 ℃ (different temperature changes in different seasons) to eliminate diseases and pests such as Escherichia coli and insect eggs; The stink of chicken manure was removed on the fourth day; On the 7th day, the compost became loose and dry and covered with white hyphae; On the 9th day, it sent out a kind of liquor flavor; On the tenth day, the bacterial fertilizer will mature

4. Crush with semi-wet material crusher

5. Then the impurities are screened out by the screening machine to make powdery organic fertilizer

6. The organic fertilizer production line can be packaged and stored by automatic packaging machine

Features of equipment for powdery organic fertilizer production line:

1. It can effectively mix livestock manure, sludge, microbial preparation and straw powder evenly, and create a better aerobic environment for material fermentation.

2. It is a kind of bio-organic fertilizer that can improve the soil quality and make green environmental protection through the principle of oxygen-consuming fermentation with livestock and poultry manure, agricultural waste, sugar factory sludge, sludge, household garbage and other pollutants.

3. It is suitable for the mode of ground strip and pile fermentation to produce bio-organic fertilizer in a factory. It has obvious advantages of low investment, low energy consumption, fast fertilizer production and large output.

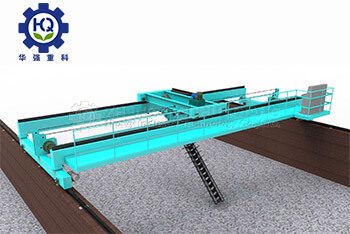

4. For ground stacking fermentation, the materials need to be piled into long strips. The organic fertilizer dumper will regularly mix and break the materials, and decompose the organic matter under aerobic conditions. The Renyuan bio-organic fertilizer tipping machine has the function of crushing, greatly saving time and labor, significantly improving the production efficiency and product quality of the organic fertilizer plant, and greatly reducing the cost.