Application of two-shaft mixer in npk fertilizer production line

Organic fertilizer granulator machine to be designed and used in different type fertilizer manufacturing process to produce the fertilizer into granulator.

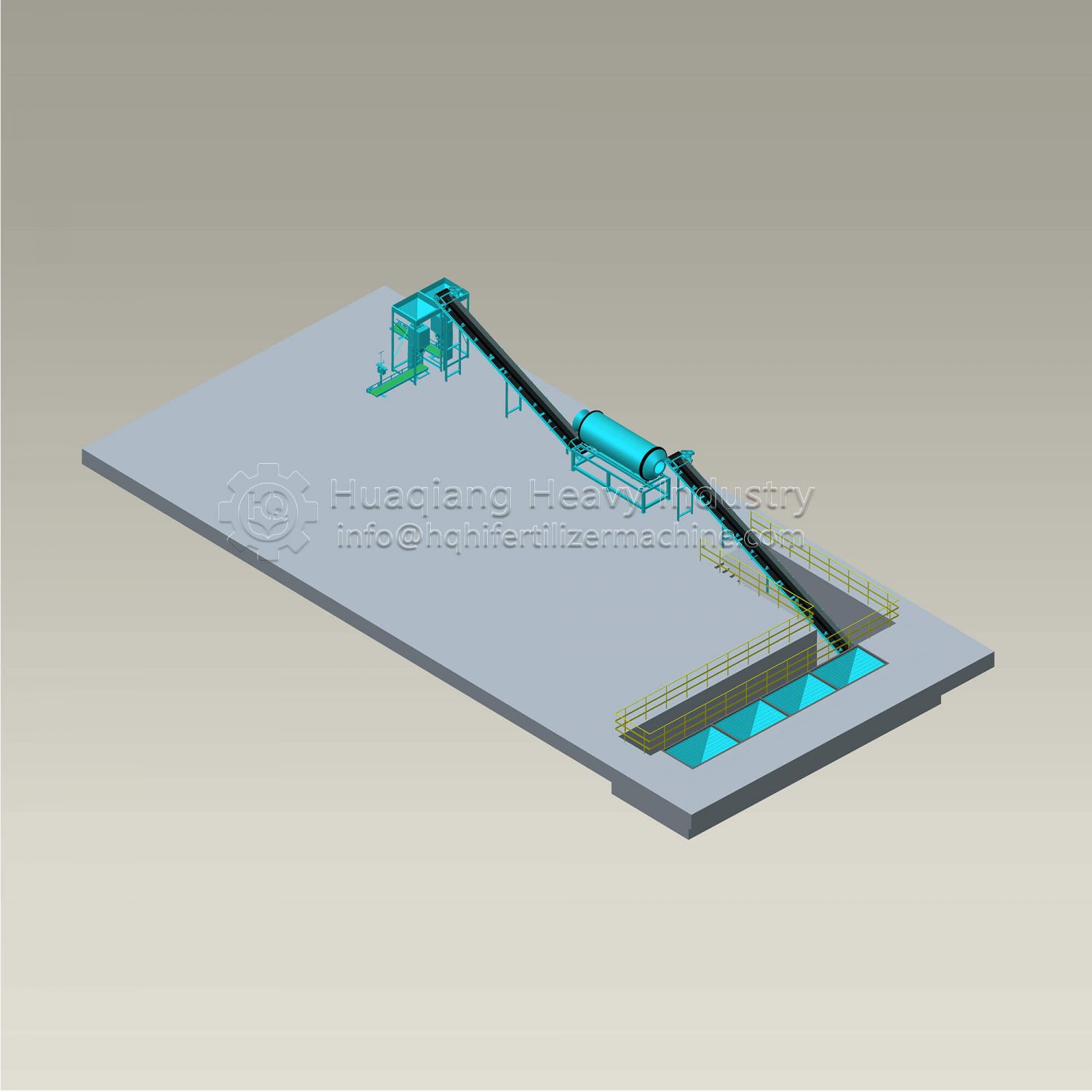

Like the rotary drum granulator machine to be used in organic fertiizer manufacturing process or npk fertilizer production line.

The roller press granulator machine to be used in the npk,compound fertilizer production line to produce compound fertilizer granulator using the extrusion method.

More other type fertilizer granulator machine to be designed and used in the fertilizer manufacturing process to finish the production process.

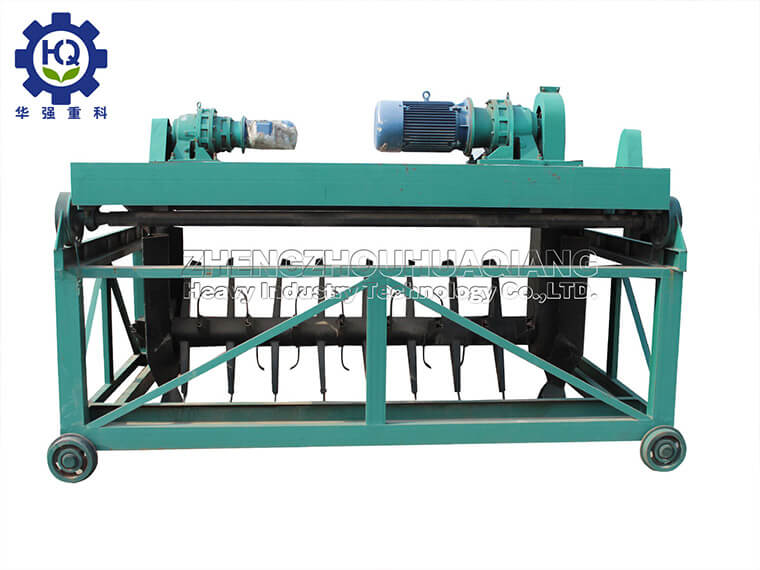

In the production process of organic fertilizer, we must choose different organic fertilizer production line equipment according to the customer’s manufacturing situation. Today, let’s take a look at the advantages of horizontal mixers and double-shaft mixers in organic fertilizer mixers:

The dual-shaft mixer uses the synchronous rotation of two symmetrical spiral shafts to add dry water and other powder materials while stirring, so that the dry powder materials can be humidified evenly, so as to prevent the humidified materials from releasing dry ash and seeping water , It is convenient to load and transport the humidified ash or transfer the humidified ash to other conveying equipment. The horizontal mixer can obtain sufficient mixing of raw materials, thereby improving the uniformity of mixing, which is suitable for the mixing of raw materials.

The double-shaft mixer is mainly composed of a shell, a screw shaft assembly, a driving device, piping, a cover, a chain cover and other components. The shell is mainly composed of plates and steel sections, welded and formed in a manufacturing plant, and assembled with other components. The shell is tightly sealed, and there will be no rise and leakage of fly ash.

Subject to feasibility, the horizontal mixer is not affected by particle size and density. It has a good effect on sticky substances. The stable mixing process reduces the damage to fragile materials, and the flying knife structure also plays a role in breaking. The horizontal structure reduces the height of the fuselage for easy installation. The forward and reverse rotation screw is installed on the same flat shaft to form a low-power, high-efficiency mixed environment.

Zhengzhou Huaqiang is willing to provide you with professional solutions and the most favorable fertilizer granulator machine price.