Granulation process of organic fertilizer production line for livestock and poultry manure

Animal manure and organic fertilizer are widely used in various fields such as farmland, fruit trees, flowers, landscaping, high-end lawns, and soil improvement, with good results. The government provides subsidies for agriculture and strongly supports this industry, so making investment choices is a very good choice..jpg)

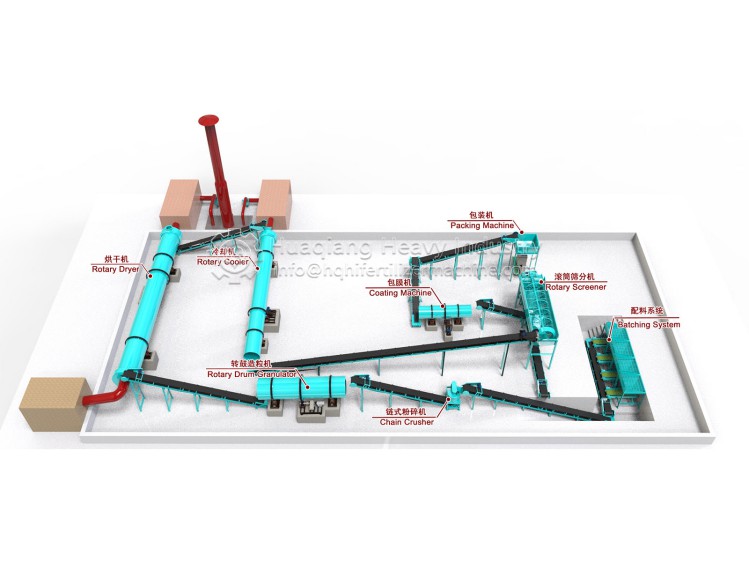

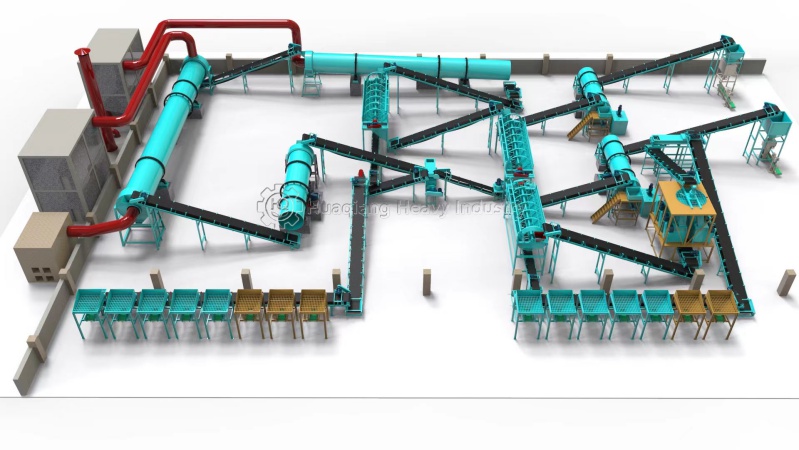

Equipment configuration and granulation process of organic fertilizer production line for livestock and poultry manure:

1. Crushing equipment: New semi wet material crusher – vertical crusher and horizontal crusher, with internal structures of chain and hammer type. No screen, even if the material is crushed from the water, it will not block.

2. Mixing equipment: Mixing mixer – including vertical mixer, horizontal mixer, double shaft strong mixer, drum mixer, etc. The internal mixing structure is divided into blade type, spiral type, etc. Design a suitable mixing structure based on the characteristics of the material. The discharge port is designed for cylinder control and baffle control.

3. Transportation equipment: Belt conveyor – mobile belt conveyor, fixed belt conveyor, etc. Belt conveyor is an indispensable economic logistics transportation equipment for forming a rhythmic production line. It has many characteristics such as strong conveying capacity, long conveying distance, simple structure and easy maintenance, and can easily implement programmed control and automated operation.

4. Granulation equipment: Organic fertilizer specific granulator – including disc granulator, new wet granulator, round throwing machine, drum granulator, coating machine, etc. Select a suitable granulator based on the characteristics of the raw materials.

5. Drying and cooling equipment: Rotary dryer – also known as drum dryer, bio organic fertilizer dryer. Because the temperature during organic fertilizer drying cannot exceed 80 ° C, our dryer adopts hot air drying mode. Cooling machine – Similar in appearance to a dryer, but with different materials and performance.

7. Coating equipment: Granular coating machine – The main body has a similar appearance to a dryer and a cooling machine, but the internal structure differs greatly. The interior of the coating machine is made of stainless steel plate or polypropylene lining. The entire machine includes a matching powder dispenser and oil pump.

8. Automatic packaging equipment: Automatic measuring packaging machine – including spiral and direct current, single head and double head, made of stainless steel and carbon steel, customized according to customer actual needs.