Organic fertilizer equipment is also known as organic fertilizer production lines. Building a complete set of organic fertilizer equipment can effectively carry out organic fertilizer production and improve the output and quality of organic fertilizer. Many businesses do not know how to establish organic fertilizer production lines, and do not know what conditions are required to build organic fertilizer production lines. Today, let me take you through.

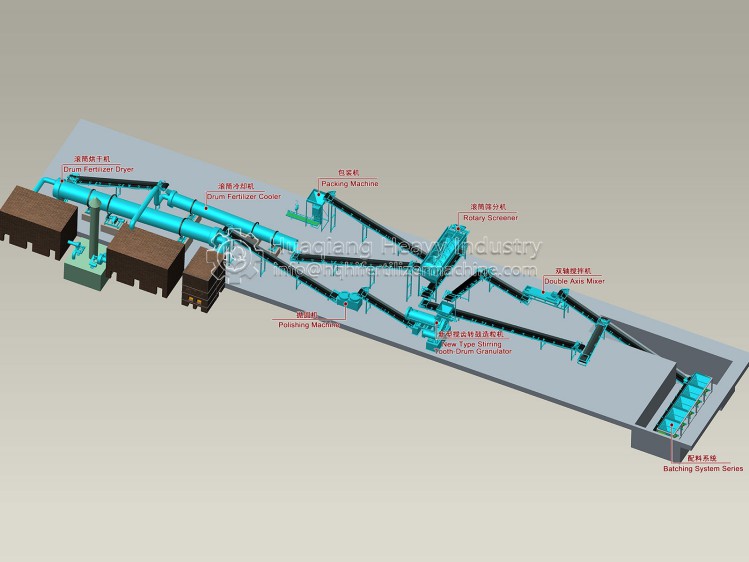

According to the process stages, the granular organic fertilizer production line process is divided into 1 crushing process; 2. Fermentation process; 3. Mixing process; 4. Granulation process; 5 Drying process; 6. Screening process; 7. Coating process; 8 Packaging process.

The complete organic fertilizer production line equipment portfolio includes: fermentation tipping machine, semi wet material crusher, horizontal mixing mixer, new organic fertilizer granulator, rounding machine, rotary dryer, rotary cooler, drum screening machine, and automatic packaging machine.

So what are the conditions for building a small organic fertilizer production line?

1. The construction of small organic fertilizer production lines should comply with environmental protection policy requirements. For environmental protection, it is not only the desire of the public, but also the policy demand for environmental protection in the development of agriculture and animal husbandry;

2. Source of raw materials, surrounding the source of raw materials, determining your factory location, site investment, transportation investment, etc;

3. The type of raw materials determines the detailed equipment used in each process stage, which affects the equipment investment price, etc;

4. Production scale: The annual output of small organic fertilizer equipment ranges from 3000 tons to 20000 tons, which determines the capacity requirements of the equipment, thereby affecting prices, etc;

5. The recycling of resources mainly relies on various ways of recycling agricultural surface pollution wastes, such as first making fuel and electric energy raw materials, and the generated biogas residue as organic fertilizer raw materials;

Other uses of this small organic fertilizer production line process can be used as feed, etc;

7. Plant construction site: It is necessary to determine the production site size and site size investment based on the planned production scale.

The most important thing for the construction of organic fertilizer equipment is to adapt measures to local conditions. A good organic fertilizer production line is not only a guarantee of output, but also a guarantee of quality. Although the organic fertilizer equipment is only a combined process, the convenience it brings to people is unimaginable. Taking an organic fertilizer processing plant with an annual output of 200000 tons as an example, the equipment for the organic fertilizer production line is essential for starting an organic fertilizer processing plant. A complete set of organic fertilizer production line equipment, from fermentation equipment, crushing equipment, stirring equipment to the final coating machine, costs between 350000 and 550000 yuan. The price difference depends on whether you choose a high configuration equipment or a medium configuration equipment.