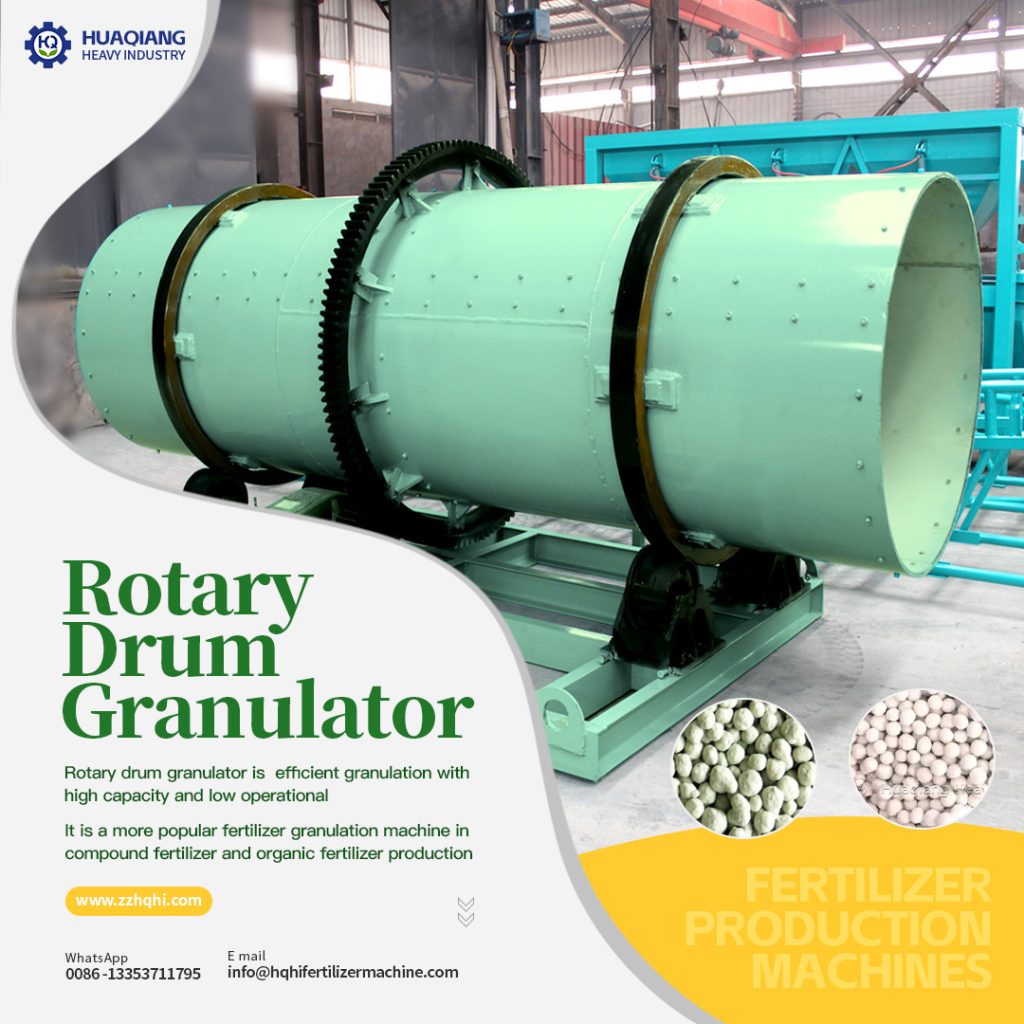

In modern fertilizer production, rotary drum granulators are redefining granulation standards with four innovative features. How do these carefully designed functions work together to create energy-efficient production miracles?

Drum granulators are commonly used in organic fertilizer production because they efficiently form moist organic material into uniform granules through a rotating drum mechanism. They are a key component in organic fertilizer production equipment, which also includes mixers, crushers, dryers, and screening equipment. While granulators specialize in granulation, complete production lines (organic fertilizer production equipment) integrate multiple steps to transform raw organic waste into high-quality fertilizer.

“From steam conditioning to self-cleaning design, each innovation makes granulation more precise and efficient”

Intelligent Steam Conditioning System

The revolutionary steam injection technology acts like precise “thermal therapy” for materials. Steam penetrates the material bed, raising temperature while dissolving salts to form a liquid phase film, enabling ideal liquid phase conditions at low moisture content. This innovation reduces drying evaporation water by 40% and energy consumption by 35%.

⚗️Controlled Ammoniation System

Ammonia gas can be precisely introduced into the drum as needed to promote chemical reactions. This controlled ammoniation technology acts like a “chemical catalyst”, not only adjusting product pH but also improving granule structure, enhancing slow-release performance by 30%.

Self-Cleaning Liner Design

The special rubber or polypropylene liners embedded in the drum wall, combined with cleverly designed air holes, form an intelligent self-cleaning system. When liners rotate to the top, they sag under their own weight, causing adhered materials to fall off automatically. This “self-renewal” mechanism solves traditional granulator sticking problems, reducing maintenance costs by 60%.

Extensive Material Adaptability:

Low-solubility Materials High-solubility Materials Organic Matter Trace Elements

Whether it’s poorly soluble potassium sulfate and potassium chloride, highly soluble urea and ammonium nitrate, or various organic materials and trace elements, this system handles all perfectly. This “non-picky” characteristic reduces formula changeover time by 80%.

Four innovations, four advantages – the drum granulator is driving fertilizer production toward greater efficiency and intelligence with its technological charm.