Bio-organic fertilizers are mainly derived from plants and animals. They are applied to the soil to provide carbonaceous substances whose basic function is plant nutrition. After processing, toxic and harmful substances are eliminated, and a large number of beneficial substances are contained. Why should organic fertilizer be made into granules?

Equipment required for the production of granular organic fertilizer:

One. Hopper automatic transmission: 1. Belt transmission. 2. Automatic feeding. 3. Avoid sticking to the wall.

Two. Vertical grinder: 1. Manganese steel blade. 2. Not afraid of damage. 3. Large output.

Three. Drum screening machine: 1. Plus seal. 2. Bring a beater. 3. Not stick to the wall

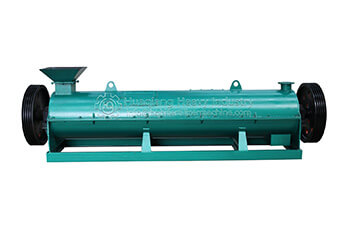

Four. Organic fertilizer granulator machine: Common organic fertilizer granulators on the market include: npk fertilizer granulator, rotary drum granulator, disc granulator machine, new organic fertilizer granulator, new two-in-one organic fertilizer granulator, flat die granulator, ring die granulator, all kinds of granulators have their own production characteristics, and the fertilizer granulator machine price vary.

Five. Cooler: 1. It can greatly increase the cooling speed, ease the labor intensity and improve the efficiency. 2. Further remove part of the water and reduce the temperature of fertilizer granules. 3. The equipment has compact structure, high cooling efficiency, reliable performance and strong adaptability.

Six. Automatic packaging machine: 1. The machine adopts a new type of fully intelligent control instrument, which automatically corrects the deviation and reports the deviation, and the fault comes from the diagnosis. 2. The parts in contact with the material are all made of 304 stainless steel, which has a long service life. 3. A printer interface is reserved, which can print production data such as packaging quantity and total weight. 4. The control box adopts sealed form, which is suitable for extreme dust environment. The tightening parts are made of stainless steel for long service life.