A NPK fertilizer production line is a modern production system that scientifically blends the three key elements, nitrogen, phosphorus, and potassium, to create compound fertilizer. From raw material processing to finished product packaging, each step embodies the principles of precision and standardization.

Raw material pretreatment is the foundation of production. Nitrogen fertilizer raw materials, primarily ammonia and urea, require crushing and screening to remove impurities. Phosphorus sources, typically monoammonium phosphate and superphosphate, are ground to a desired fineness. Potassium salts, primarily potassium chloride and potassium sulfate, are dried to reduce moisture. These three raw materials are metered according to crop requirements and precisely mixed using an intelligent batching system.

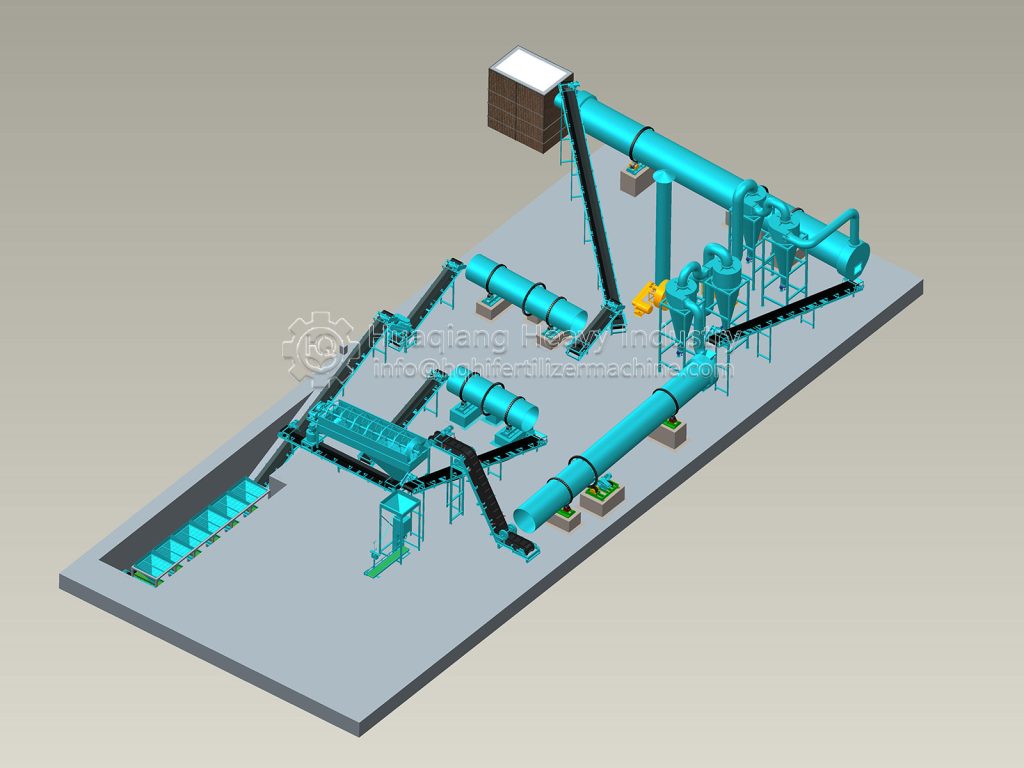

Mixed granulation is the core step. The pretreated raw materials enter the agitator for thorough homogenization before being fed into the rotary drum granulator. The inclined rotating drum drives the material, while a spray system adds an appropriate amount of water or steam, allowing the material to gradually agglomerate into granules through friction and adhesion. Particle size can be controlled by adjusting the drum speed and the material’s residence time, resulting in rounded granules. This process is highly adaptable and can handle a variety of raw material formulations. It also produces granules with high strength and good water solubility, making it suitable for large-scale continuous production. After granulation, the granules are screened and graded, and unqualified granules are returned for reprocessing to ensure consistent product size.

Post-processing determines fertilizer stability. The granules enter a dryer, where moisture is controlled within a reasonable range at an appropriate temperature to prevent clumping. After cooling, they are sprayed with an anti-caking agent in a film coating machine to form a protective film. Finally, they are packaged in standard bags by a quantitative packing machine for sale.

NPK fertilizer production line transforms chemical raw materials into “nutrient packs” that provide a balanced supply to crops. This not only addresses the nutrient imbalance of single fertilizers, but also improves fertilizer utilization through industrialized production, providing efficient and stable nutrient support for modern agriculture.