In the context of global agricultural sustainability, organic fertilizer production has become a crucial link in resource recycling. Through systematic production processes, various organic wastes are transformed into safe and efficient fertilizer products, achieving the dual goals of “harmless treatment” and “resource utilization.”

Raw Material Pretreatment: Laying the Foundation for Fermentation

The first step in producing quality organic fertilizer is raw material pretreatment. This stage requires mixing main materials such as livestock manure, municipal sludge, and kitchen waste with auxiliary materials like straw, sawdust, and rice husks in proper proportions. The key is to control the carbon-to-nitrogen ratio at 25-30:1, which is the optimal fermentation ratio for microorganisms, while adjusting material moisture to the ideal range of 55%-65% through water addition or sun drying. Screening machines play an important role in this stage, effectively removing non-degradable impurities such as stones, metals, and plastics, creating favorable conditions for subsequent fermentation.

Aerobic Fermentation: The Core of Harmless Treatment

Aerobic fermentation is the core step in the entire production process, playing a crucial role in the harmless treatment. The pre-treated material is piled into appropriately sized windrows or sent to fermentation tanks, and is periodically turned by specialized equipment such as turning machines. At the ideal fermentation temperature of 55-65℃, over 90% of harmful microorganisms are effectively removed, and organic matter is completely decomposed through microbial action. Under industrial production conditions, the fermentation cycle can be shortened to 7-15 days. During this period, close monitoring of temperature and humidity is necessary to ensure the material reaches full maturity—characterized by being odorless, dark brown, and loosely brittle.

Post-treatment Purification: Enhancing Product Quality

Fermented materials require meticulous post-processing to meet granulation requirements. A drum screen can separate incompletely decomposed residues, which can be returned to the fermentation process for secondary processing. To achieve optimal moisture conditions for granulation, the material may need to be dried to a moisture content of 30%-35%. Furthermore, appropriate nutrients need to be added to the formula according to the nutritional standards of the target product to ensure the final product meets relevant quality standards.

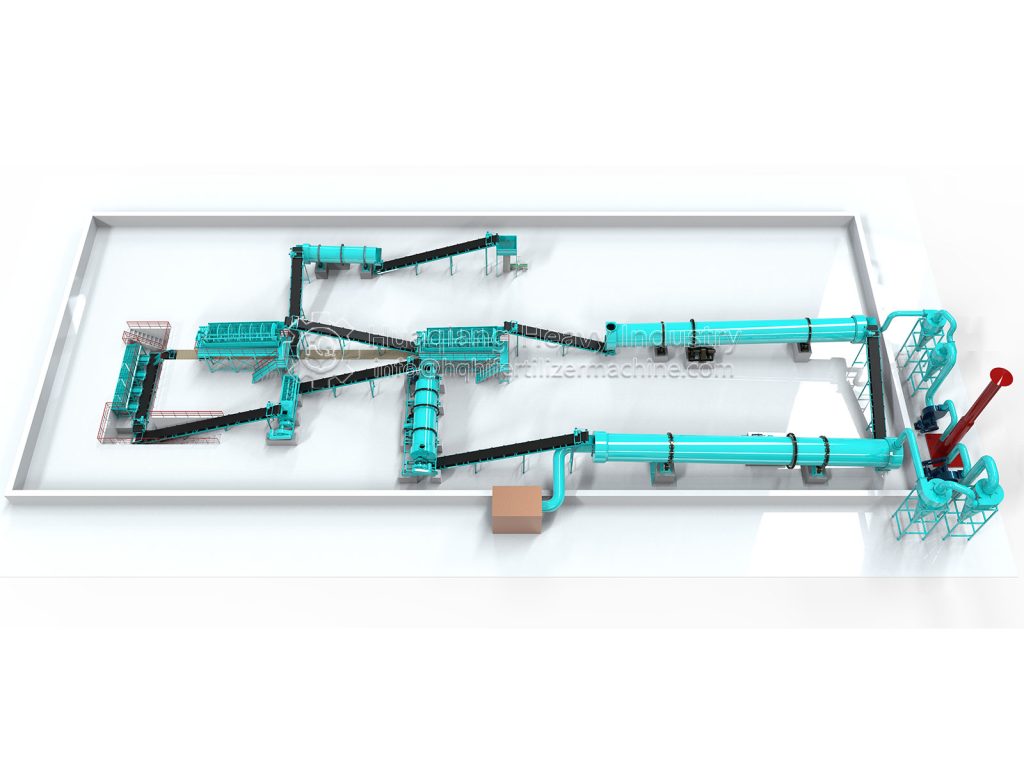

Forming Processing and Final Product Packaging

Granulation technology imparts commercial characteristics to organic fertilizers, making them easy to store, transport, and apply. Specialized granulation equipment processes formulated materials into uniformly sized granules, which are then cooled and screened a second time to ensure product quality. The final packaging stage utilizes automated equipment for standardized packaging and affixes clear product information labels, preparing the product for market sale.

Successful Practice in Large-scale Production

Taking an organic fertilizer plant that processes 500 tons of livestock and poultry manure per day as an example, the company uses a scientifically proportioned mixture of pig manure and corn stalks, employing advanced disc turning equipment to complete the fermentation process within 10 days. After meticulous post-processing and granulation, it ultimately produces high-quality organic fertilizer that meets national standards, effectively serving the surrounding agricultural production. This large-scale production model not only solves environmental pollution problems but also creates considerable economic benefits.

The organic fertilizer production line perfectly embodies the circular economy concept, transforming waste into valuable resources through advanced organic fertilizer fermentation processes. Modern organic fertilizer factory operations utilize sophisticated fertilizer manufacturing plant equipment to convert organic materials into safe, reliable agricultural inputs. The core organic fertilizer granulator technology ensures consistent product quality while optimizing production efficiency.

Despite the initial investment in organic fertilizer machinery price, the long-term environmental and economic benefits make it a sustainable solution for modern agriculture. As production processes continue to evolve, these integrated systems demonstrate how technological innovation supports global agricultural sustainability while reducing environmental pollution, creating a closed-loop system that benefits both farming communities and ecological preservation.