Organic fertilizer production lines rely on agricultural waste conversion to achieve resource recycling, but their production processes are complex and susceptible to internal and external factors. They face multiple risks and challenges, requiring accurate identification and proactive prevention.

Raw material supply risks are the primary obstacle to production line operations. Organic fertilizer raw materials primarily consist of livestock and poultry manure and crop straw, which are significantly constrained by natural and social factors. Seasonal variations can lead to a “peak season surplus” and “off-season shortage” in straw supply, such as abundant straw after the autumn harvest and a tight supply in the spring. Sudden animal epidemics can cause farm closures, directly cutting off the source of livestock and poultry manure. Furthermore, raw material quality fluctuates significantly. Excessive levels of heavy metals in manure or moldy straw can result in substandard quality in the finished organic fertilizer, impacting sales and potentially leading to environmental complaints.

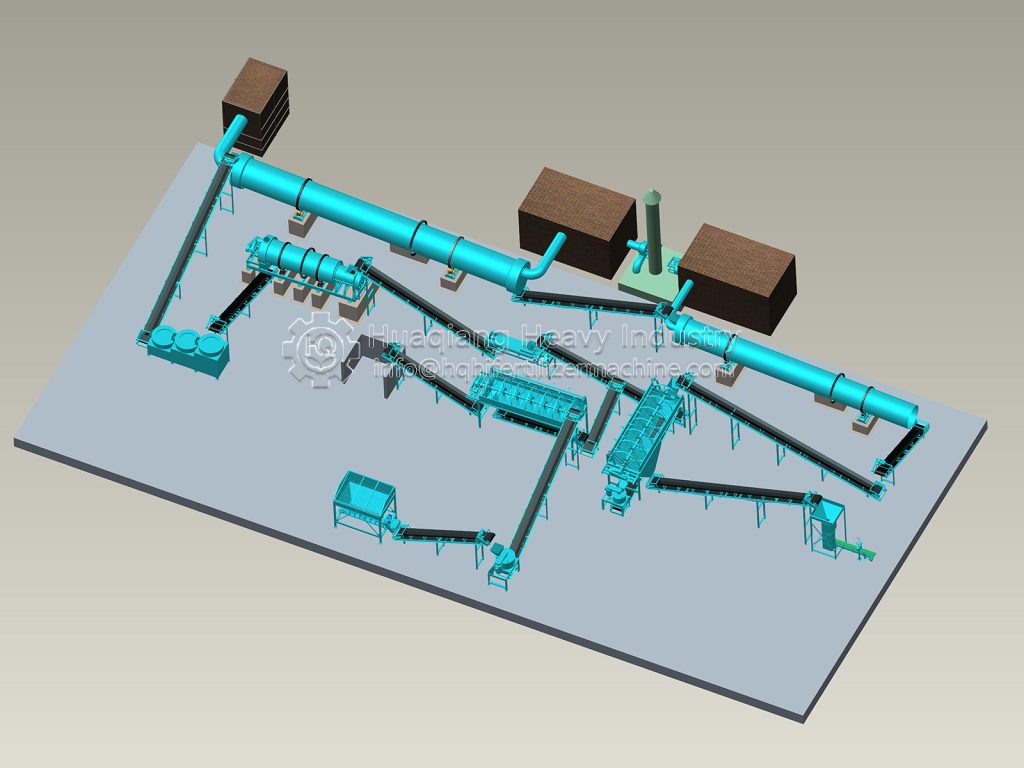

Equipment operation risks directly threaten production continuity. Organic fertilizer production lines involve multiple processes, including fermentation, crushing, granulation, and drying. Long-term, high-load operation of core equipment can lead to malfunctions. Leaks in the hydraulic system of the fermentation granulator can lead to uneven granulation and prolonged composting. Wear on the granulator’s molds can reduce pellet formation and increase raw material loss. Failure of the dryer’s hot air furnace can result in incomplete drying of the material, leading to caking and deterioration. If critical equipment shuts down, the entire production line can be paralyzed, resulting in significant economic losses.

Production safety risks harbor significant hidden dangers. During the fermentation process, microorganisms decompose organic matter, producing gases such as methane and ammonia. Methane is flammable and explosive. If the workshop is poorly ventilated and concentrations exceed standards, it can easily cause an explosion when exposed to open flames. The drying process uses high temperatures, making excessively thick material accumulation or improper temperature control a fire hazard. Furthermore, some equipment components lack effective protection, and improper operator operation can lead to mechanical injuries.

External environmental risks should also not be underestimated. At the market level, the demand for organic fertilizers is affected by the agricultural production cycle. During the peak season, products are in short supply, while during the off-season, inventory is piling up and prices fluctuate sharply. At the policy level, upgraded environmental protection standards may require production lines to increase investment in pollution control equipment. Adjustments to agricultural subsidy policies will directly affect product market competitiveness. If organic fertilizer production lines fail to adapt to policy changes in a timely manner, they may face compliance risks and operational pressures.