Starting an organic fertilizer production line involves more than just purchasing equipment—it hinges on two crucial factors: raw material supply and fermentation technology. Failure in any of these steps can lead to substandard product or even stagnation.

Understanding the fundamental differences between raw material requirements for NPK and organic fertilizer production lines is essential for planning a successful operation.

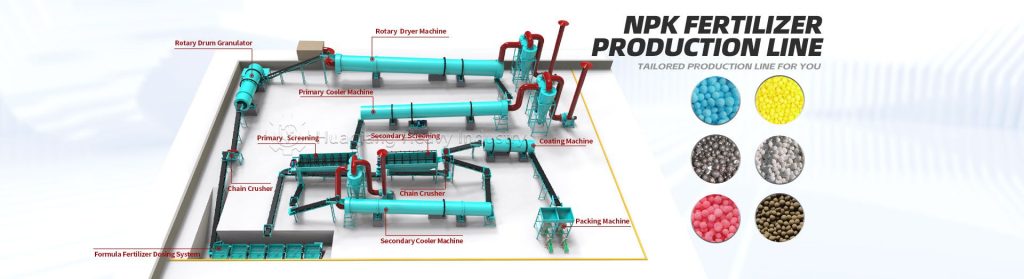

NPK Fertilizer Production

Requires precisely measured chemical compounds—primarily nitrogen (N), phosphorus (P), and potassium (K) sources. These mineral-based ingredients need exact proportioning to achieve specific nutrient ratios.

Organic Fertilizer Production

Depends on organic waste materials like animal manure, crop residues, and food waste. These materials require proper composting and fermentation to stabilize nutrients and eliminate pathogens.

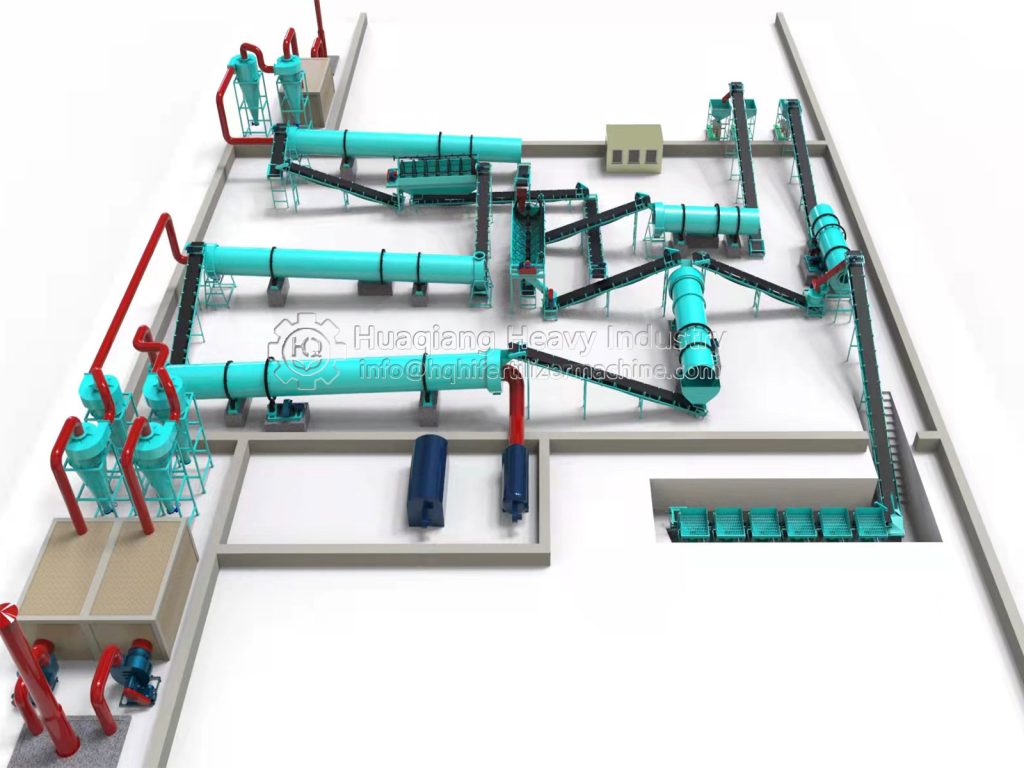

Essential Equipment for Fertilizer Production

Beyond raw material considerations, selecting the right machinery is critical for efficient production:

Ensures homogeneous blending of ingredients for consistent nutrient distribution

Transforms mixed materials into uniform pellets for easier handling and application

Automates the final packaging process, ensuring proper sealing and accurate weights

Successful fertilizer production—whether organic or NPK—requires careful consideration of both raw material specifications and appropriate equipment selection. The fertilizer mixer machine, fertilizer granulator, and fertilizer packing machine work together to transform raw materials into market-ready products, but their effectiveness depends entirely on proper raw material preparation and processing techniques.

Raw materials are the lifeblood of organic fertilizer.

These production lines rely on livestock manure, crop straw, and agricultural waste—materials that must be abundant and local. Imagine building a production line in an area with few farms: transporting manure from 100 kilometers away would increase costs by 30-40%, eroding profits. Conversely, a plant located near poultry farms or rice paddies would thrive: fresh manure (rich in nitrogen) and straw (rich in carbon) create the perfect nutritional combination, while short transportation distances reduce the risk of spoilage.

Fermentation technology is equally crucial.

The value of organic fertilizer lies in its nutrient content and microbial activity, both of which rely on controlled decomposition. A poor fermentation process—overheating, overcooling, or insufficient aeration—can harbor harmful pathogens or reduce nitrogen content by 20% or more. Established production lines use automated compost turners to regulate temperature (55-65°C, optimal for weed control) and aeration, ensuring consistent nutrient levels (typically 3-5% total nitrogen, phosphorus, and potassium) and meeting organic certification standards.

Where do these lines thrive?

In regions with strict environmental regulations and a thriving organic agriculture sector. Take Yunnan’s tea-producing regions, for example: strict restrictions on chemical inputs drive demand for organic fertilizers, while local bamboo and tea waste provide a stable source of raw materials. Similarly, in Zhejiang’s vegetable hubs, consumers pay premium prices for organic produce, making organic fertilizer lines not only compliant but also highly profitable.

In short, organic fertilizer lines succeed when raw materials are sourced locally and the fermentation process is precise. It’s a marriage of geography and technology—a combination that, when chosen correctly, nourishes the crop while generating profit.