Large wheel compost turners are widely used in organic waste treatment due to their efficient compost turning capabilities and outstanding performance. Understanding their application scenarios and precautions will help you maximize their effectiveness.

1. Application in Tank Fermentation

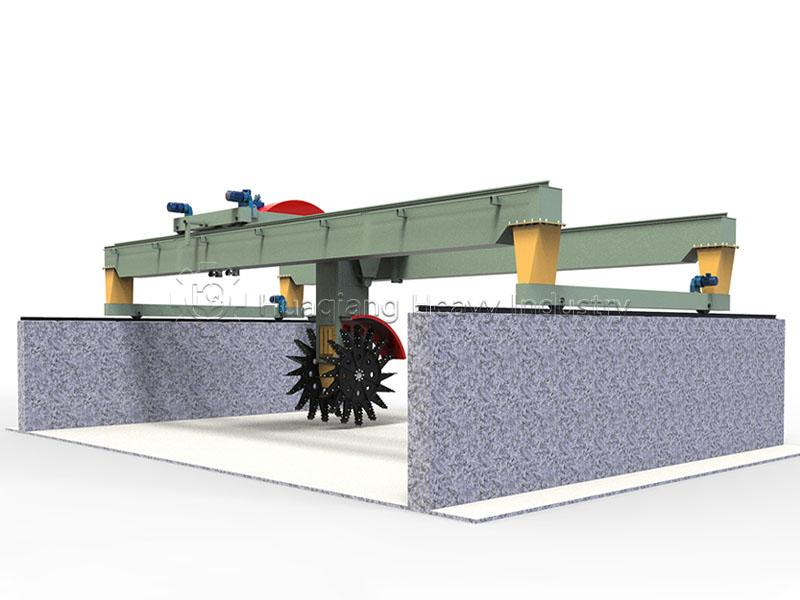

In tank fermentation, large wheel compost turners move along fixed tracks within the fermentation tank. The fermentation tank is typically constructed of concrete or steel and has a certain width and depth, typically 3-8 meters wide and 1-2 meters deep. The large wheel compost turner’s wheels move along the tracks within the tank, turning the material through rotation. This application scenario is suitable for large-scale centralized processing.

2. Composting in Windrow Fermentation

For windrow fermentation, large wheel compost turners require tires or tracks to enable free movement in open areas. Windrow fermentation typically involves stacking organic waste into windrows, typically 2-5 meters wide and 1-1.5 meters high. Large wheel compost turners shuttle between windrows, turning the material with their rotating wheel. For small farms processing organic waste using windrow fermentation, large wheel compost turners can flexibly operate between windrows to complete the turning task.

Large wheel compost turners play an important role in both tank and windrow fermentation, and are suitable for organic waste treatment projects of varying scales and site conditions.