In today’s pursuit of sustainable development, the bio-organic fertilizer production line represents a specialized evolution of the broader organic fertilizer production line category, specifically designed to maximize microbial activity and nutrient preservation. These sophisticated systems transform various agricultural wastes into high-quality bio-organic fertilizers through controlled fermentation processes.

While the organic fertilizer line focuses on recycling organic matter, the NPK fertilizer production line specializes in creating precise nutrient formulations, and the bulk blending fertilizer line offers customized nutrient combinations—together forming a comprehensive approach to soil nourishment that addresses both organic matter content and precise nutrient requirements.

This integrated approach not only addresses waste management challenges but also provides a complete spectrum of fertilization solutions for modern agriculture, from enhancing soil structure with organic matter to delivering targeted nutrition through specialized formulations.

The Marvelous Transformation Journey

The heart of bio-organic fertilizer production lies in microbial fermentation technology. These microscopic biological workers convert nutrients in organic waste into forms that plants can directly absorb, while simultaneously improving soil structure and enhancing soil fertility. The entire process resembles a meticulously orchestrated natural symphony, with the organic fertilizer production machine serving as the conductor of this performance.

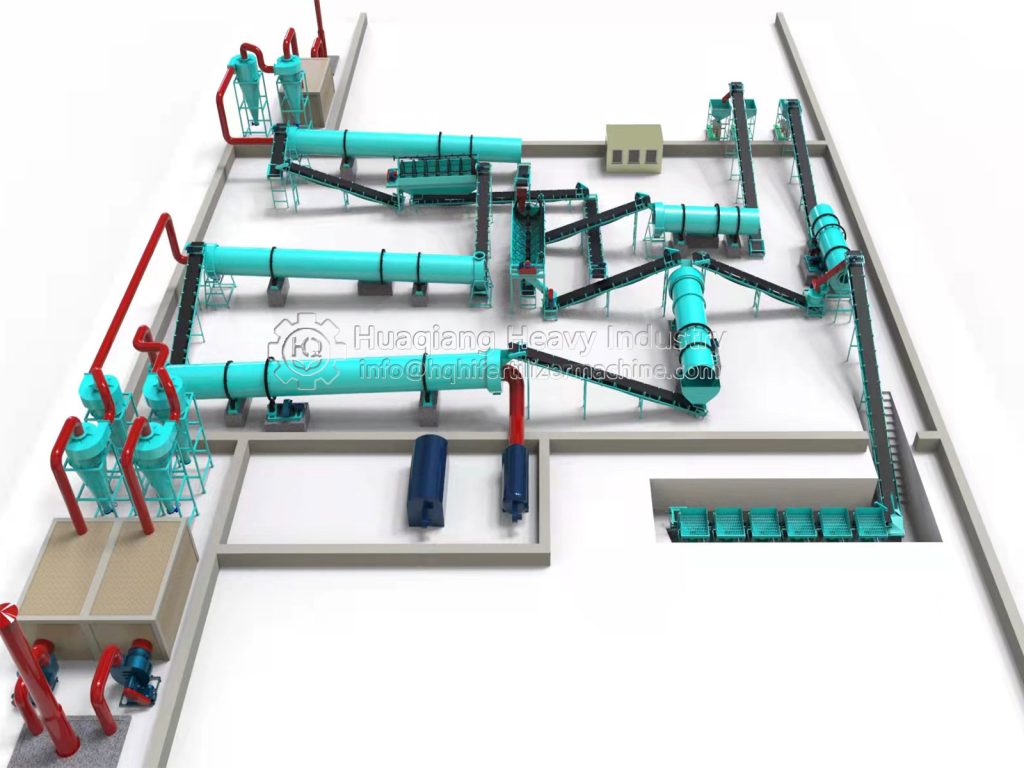

Modern organic fertilizer manufacturing machines have evolved into highly automated systems that can precisely control every parameter of the fermentation process, ensuring the production of stable and highly effective bio-organic fertilizers.

The Four-Step Transformation from Waste to Treasure

Raw Material Pretreatment: The production line first collects various organic wastes and processes them into particles suitable for fermentation through a crusher. These materials are then mixed with a certain proportion of water and fermentation agents to adjust humidity and microbial activity, preparing for the fermentation process.

Efficient Fermentation Process: The pretreated materials enter fermentation equipment where they undergo high-temperature fermentation through microbial action. This process requires regular turning to provide sufficient oxygen, control fermentation temperature, and promote organic matter decomposition. Modern organic fertilizer production machines can precisely monitor key parameters such as temperature, humidity, and oxygen content, ensuring efficient fermentation.

Refining Stage: After fermentation, the materials undergo drying to remove excess moisture, improving the stability and storage capacity of the organic fertilizer. The dried organic fertilizer raw materials are then processed into granules through a granulator for easy transportation and use. A screening machine selects particles that meet size requirements and mixes them evenly with other additives to enhance the nutritional completeness and biological activity of the organic fertilizer.

Quality Assurance: Finally, an automatic packaging machine packages the finished bio-organic fertilizer into bags or boxes, followed by quality testing to ensure products meet national or industry standards. Each organic fertilizer manufacturing machine plays an indispensable role in this process.

The bio-organic fertilizer production line represents not only a technological innovation but also the perfect embodiment of circular agriculture principles. Through advanced organic fertilizer production machines, we can transform waste into valuable resources, reducing environmental pollution while enhancing soil health, providing practical solutions for sustainable agricultural development. This system demonstrates how humanity can cleverly utilize natural processes to create greener, more efficient agricultural production models.