Granulation Wizardry: Turning Animal Waste into Agricultural Treasure

In the alchemy of organic fertilizer production, the granulator acts as a master formulator, transforming various animal manures into valuable “black gold.” But did you know? Different manure types require distinct granulation magic—choose the wrong equipment, and even premium materials can become a production nightmare.

The Granulation Code for Animal Manures

Pig manure: Moderate viscosity but fibrous, ideal for the rotating alchemy of disc granulators. These “moderates” produce uniformly round pellets, like perfectly kneaded dough.

Cow dung: Loose texture with high moisture, demands the powerful molding of extrusion granulators. These “hardliners” act like hydraulic presses, compacting loose dung into precise pellets.

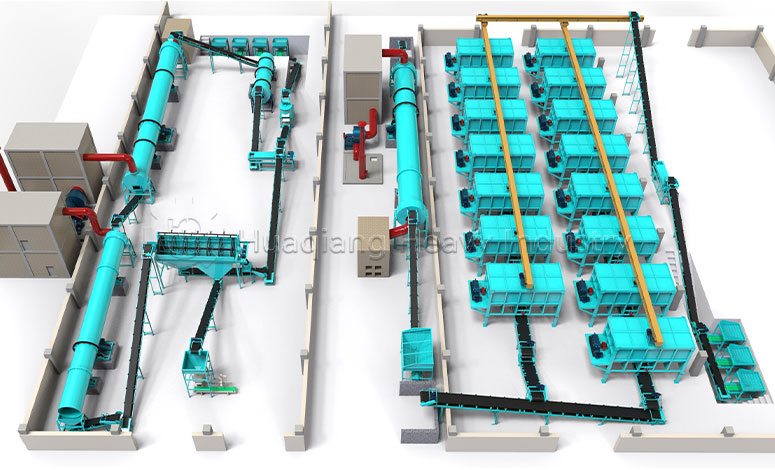

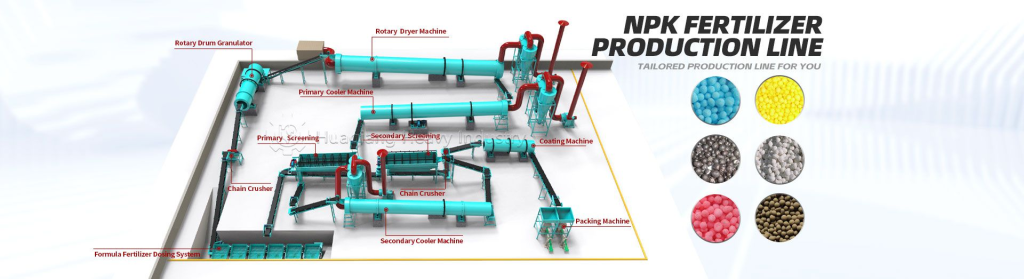

Poultry litter: High nitrogen but prone to caking, finds its match in rotary drum granulators. These “mediators” achieve perfect harmony through constant tumbling with additives.

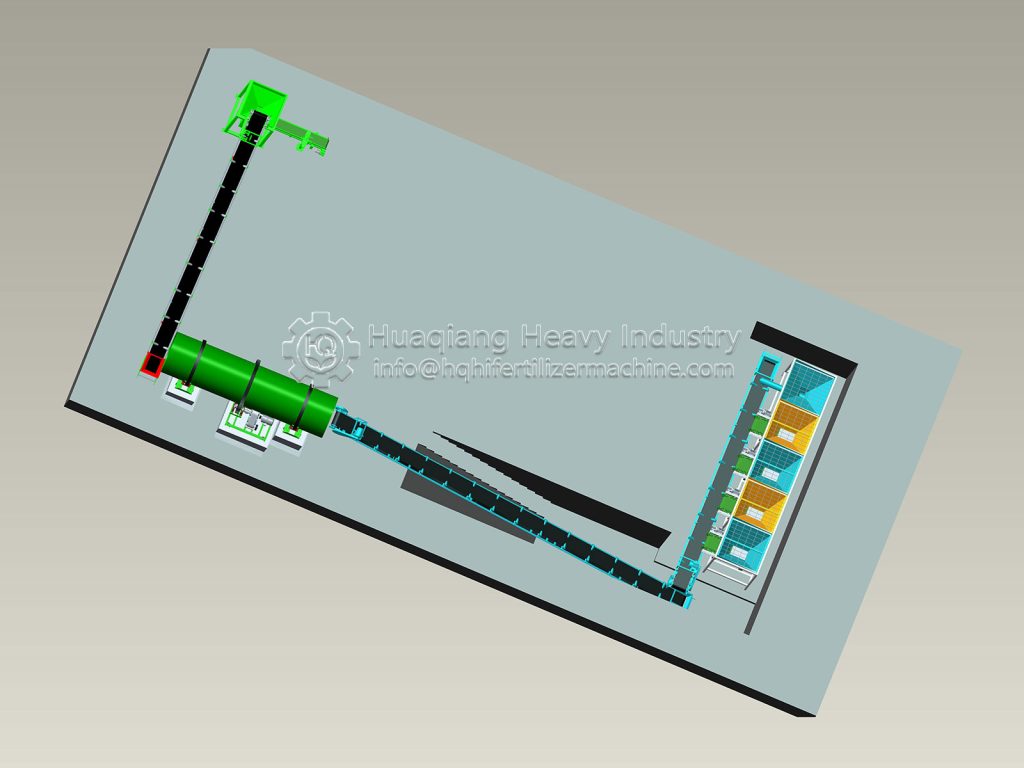

Golden Production Line Combinations

Tailored production lines for different manures:

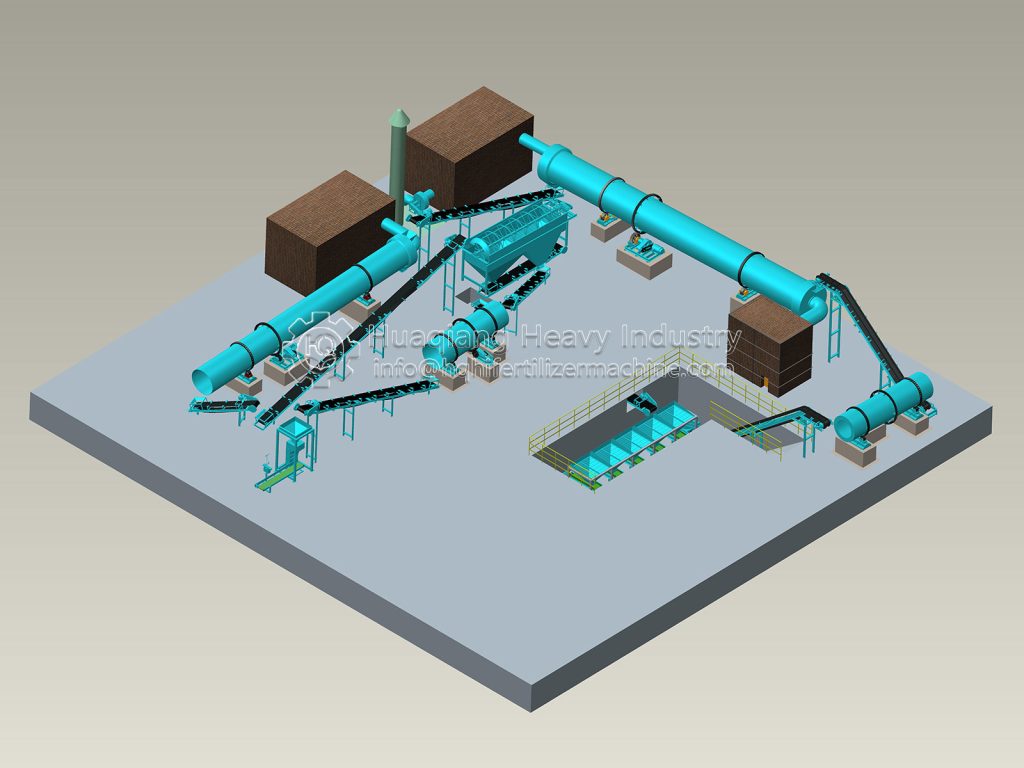

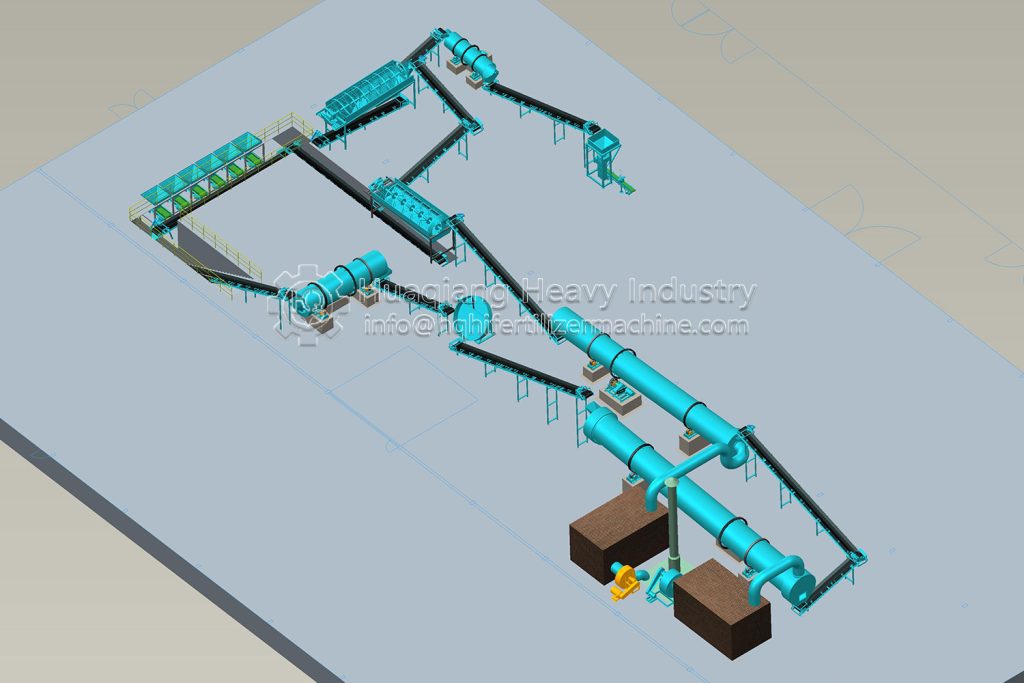

• Pig manure: Fiber crusher + Disc granulation + Low-temperature drying

• Cow dung: High-efficiency dewaterer + Extrusion + High-temperature sterilization

• Poultry waste: Precision batching system + Rotary granulation + Slow-release coating

When these equipment combinations perform in concert, once-offensive animal waste undergoes a magnificent transformation. Next time you see those uniform organic fertilizer pellets, remember: this represents not just scientific triumph, but industrial artistry at its finest.