How to maintain the NPK organic fertilizer production line in case of equipment failure

High concentration compound fertilizer production process by drum steam granulation, high, medium and low concentration compound fertilizer production process by disc granulator without steam granulation, compound fertilizer anti caking technology and high nitrogen compound fertilizer production technology. Now there are ammonia acid and ammoniated spray granulation methods in the market of organic fertilizer equipment. They are suitable for domestic market and are suitable for large, medium and small enterprises in China.

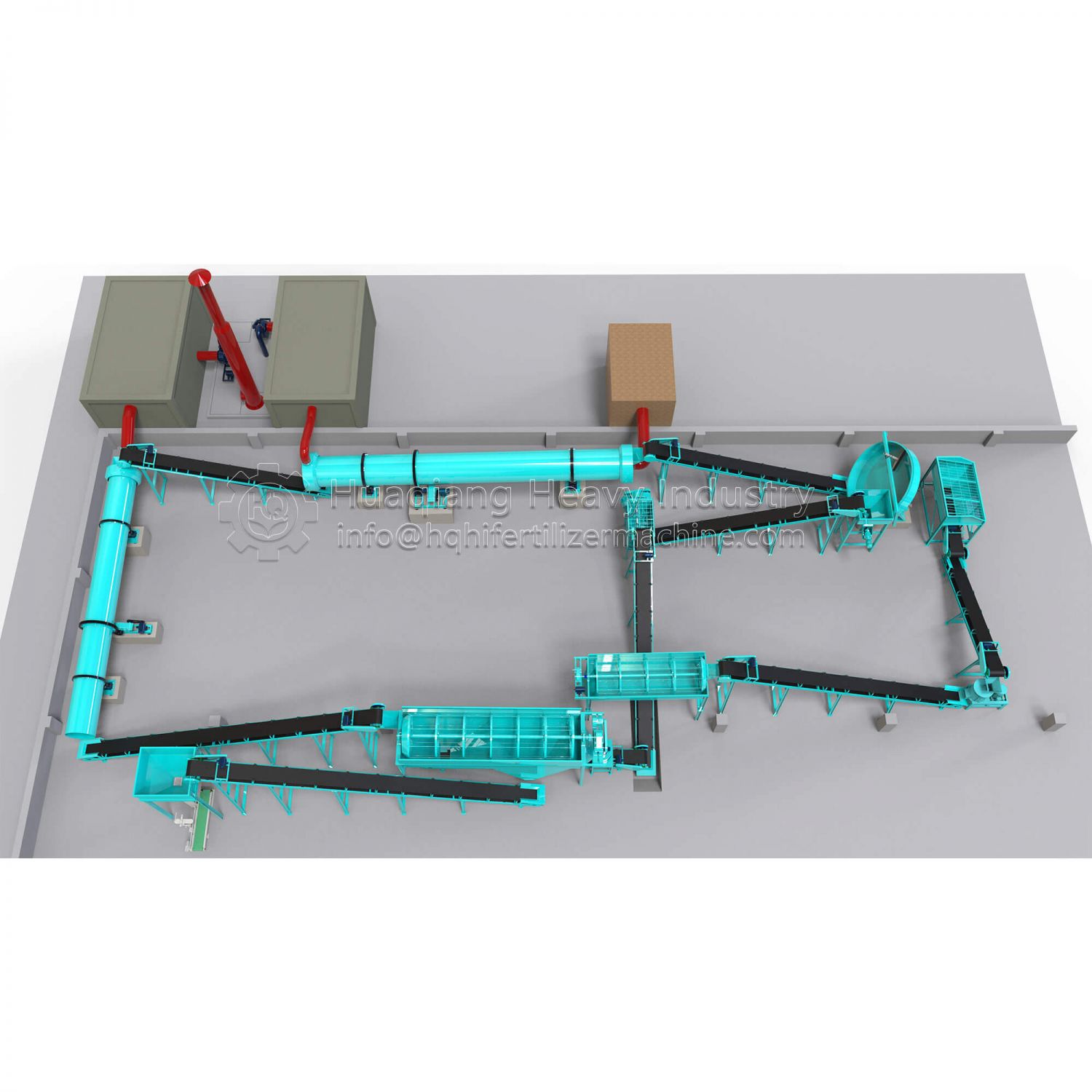

The organic fertilizer production process is mainly to mix organic solid wastes with a water content of less than 60% with auxiliary materials (plant straws, etc.), microbial fermentation inoculants, etc., and make them fully decomposed, sterilized, and sterilized through continuous pool-type aerobic fermentation. Deodorize and remove water. The moisture content of the decomposed material is generally in the range of 30-35%. After screening and magnetic separation, it can be directly used for granulation to produce spherical organic fertilizer, or to produce powdery organic fertilizer after further drying.

Details often determine success or failure. For the daily maintenance of organic fertilizer equipment, we must pay attention to the following two points:

First of all, people must be assigned responsibilities, and daily inspections and records must be made. Important parts of the equipment (vulnerable parts, motors, reducers, screens, bearings, crushing shafts, etc.) must be carried out in accordance with the requirements of the instructions every day before get off work. Necessary lubrication and maintenance, if damaged, should be replaced or repaired in time to avoid affecting normal production in the next two days.

Secondly, if the fertilizer manufacturing process needs to be stopped during the off-season, the remaining organic fertilizer raw materials in the equipment should be cleaned out to avoid the residues in the equipment and aggravate the corrosion of the equipment. The equipment should be turned on every 1-2 days after the off-season is stopped. Idling for 10-20 minutes, so that the equipment can be used normally when it is put into production again.

.jpg)