Large Wheel Composting Turner: The Core Power Equipment for High-Efficiency Aerobic Composting

In large-wheel organic waste composting systems, large wheel compost turning machines, with their efficient aeration and mixing capabilities and stable operating performance, have become the core equipment for aerobic composting in enclosed fermentation trenches. This equipment uses the fermentation trench as its working platform, and through the high-speed rotation of its toothed rotating wheels and the track-based movement of the entire machine, it achieves multiple functions such as aeration, mixing, crushing, and longitudinal transfer of organic materials. It precisely controls the oxygen, temperature, and humidity conditions during the composting process, creating an optimal environment for the metabolic activity of beneficial microorganisms, thereby significantly shortening the fermentation cycle and ensuring uniform and stable compost product quality. It is widely used in large-scale farms, urban organic waste treatment plants, and large-scale organic fertilizer production enterprises.

The working principle of the large wheel compost turning machine revolves around “precise control + efficient operation,” forming a continuous closed-loop composting intensification process. In the pre-operation setup phase, the pre-treated organic waste (such as a mixture of livestock and poultry manure, crop straw, oil palm empty fruit bunches, and conditioning agents) needs to be evenly loaded into the pre-set long fermentation trenches. The material loading height is usually controlled at 1.2-1.8 meters to ensure that the rotating wheels can fully penetrate and turn the material. Dedicated tracks are pre-set on both sides of the fermentation trench. The flatness of the tracks directly affects the stability of the equipment’s operation; generally, the track error should not exceed 5 millimeters to avoid machine shaking or jamming during operation.

During the operation phase, the movement of the equipment and the material processing work in efficient synergy. After the drive system is started, the motor transmits power to the driving wheels through the gearbox and transmission device, driving the entire machine to move at a constant speed along the fermentation trench track. The travel speed can be adjusted according to the degree of material decomposition, usually 0.5-1.5 meters per minute. At the same time, the large toothed rotating wheels (single or double wheels) of the rotating system rotate at a high speed of 30-50 revolutions per minute. The toothed structure precisely cuts into the compost pile, thoroughly crushing the lumpy materials and breaking up anaerobic areas formed by material clumping. Under the action of the rotating wheel, the material is lifted upwards and evenly scattered backward, achieving comprehensive mixing of the surface, middle, and bottom layers of the pile. This also forces fresh air into the material gaps, enabling efficient aeration. During the scattering process, the material is in full contact with the air, allowing harmful gases such as carbon dioxide and hydrogen sulfide to be released from the inside of the pile, effectively preventing the generation of unpleasant odors.

The precise control of the hydraulic system is the key guarantee for the flexible operation of the equipment. After the equipment completes the turning operation of a section of the fermentation trench, the hydraulic lift can quickly raise the rotating wheel. At this time, the drive system moves the equipment back along the track at a speed of 2-3 meters per minute, significantly improving operating efficiency. After reaching the starting point of the fermentation trench, the hydraulic system lowers the rotating wheel again, entering the next round of turning operations. This automated “operation-return” switching requires no manual intervention and can achieve 24-hour continuous operation, ensuring the continuity of the composting process. In addition, the hydraulic system of some high-end models can also adjust the cutting depth of the rotating wheel, flexibly adjusting according to the material thickness and density to further optimize the turning effect.

The efficient operation of the equipment relies on the coordinated cooperation of four core components. The drive system, as the “power heart,” usually uses a high-power three-phase asynchronous motor, coupled with a reduction gearbox and chain transmission device, ensuring stable and efficient power output and adapting to long-term high-load operation; some models are also equipped with variable frequency speed control function, achieving stepless adjustment of travel speed and rotating wheel speed. The rotating system is the “operation core,” and the toothed rotating wheel has a specially designed tooth shape and is made of wear-resistant alloy material, ensuring both crushing effect and extended service life; the blades on the wheel assist in material throwing and mixing, improving material uniformity. The moving mechanism consists of walking wheels and track guiding devices. The walking wheels use solid rubber wheels or steel wheels, and together with the guide wheels, ensure that the equipment travels accurately along the track without deviation. The hydraulic system, as the “control center,” consists of hydraulic pumps, hydraulic cylinders, solenoid valves, and other components. It achieves the smooth lifting and lowering of the rotating wheel through changes in hydraulic oil pressure, with fast response speed and high control accuracy. The application of large-scale wheeled compost turning machines has significantly improved the efficiency and quality of large-scale composting. Through continuous turning and aeration, the oxygen content of the compost pile can be stably maintained at 15%-20%, and the temperature controlled within the optimal maturation range of 60-65℃. This not only quickly kills pathogens and weed seeds but also accelerates the reproduction and metabolism of beneficial microorganisms, shortening the fermentation cycle of traditional composting from over 45 days to 20-30 days. At the same time, the uniform mixing ensures balanced nutrient content in the compost product, increasing the organic matter content by 10%-15%, providing a solid guarantee for the production of high-quality organic fertilizer and promoting the resource utilization of organic waste towards automation, high efficiency, and environmental friendliness.

Integrated System: From Composting to Bio-fertilizer Granulation

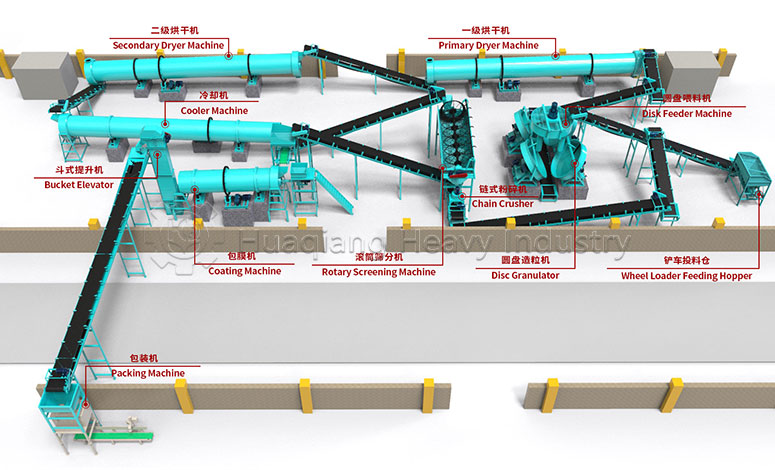

Following the efficient aerobic processing by the core large wheel compost turning machine, the matured compost becomes the primary raw material for value-added bio-fertilizer production. This advanced fermentation composting technology for organic fertilizer, which may utilize either a large wheel compost turner for wide trenches or a chain compost turner equipments required for bio-fertilizer production is integrated. This begins with precise formulation, where the compost is blended with complementary powdered ingredients like microbial inoculants, mineral powders, or amendments. For accurate recipe execution, plants typically employ a multiple silos single weigh static batching system for batch-based precision or a single silos single weigh dynamic batching system for continuous, high-volume blending.

The subsequent granulation stage is crucial for product standardization. A disc granulation production line is often the optimal choice for processing the powdery, compost-based blend. In this system, the homogenized mixture is fed into a rotating, inclined disc where fine particles adhere and grow into dense, spherical granules through a layering and tumbling action—a process perfectly suited to the physical characteristics of compost produced by an agriculture waste compost fermentation machine. This seamless integration from primary fermentation composting turning technology to final shaping creates a closed-loop, automated production line that maximizes resource recovery and product value.

This holistic approach ensures that organic waste is not merely processed but systematically upgraded into a commercial-grade, easy-to-handle fertilizer. It exemplifies modern, circular agri-technology, turning environmental challenges into sustainable agricultural inputs with improved nutrient delivery, storage stability, and market appeal.