Screw Conveyors: A Backbone in Material Handling Across Multiple Industries

In numerous industries, including chemical raw material transfer, building material production batching, food processing conveying, environmental solid waste treatment, and coal mining transportation, efficient and clean material conveying is a core element ensuring smooth production processes. Screw conveyors (also known as screw feeders or screw elevators), as a simple and stable conveying equipment, utilize a unique screw drive design to achieve horizontal, inclined, and even vertical conveying of granular and small lump materials, making them a backbone device in material conveying systems across various industries. They push materials through the rotation of screw blades, completing the conveying operation in a closed environment, ensuring both conveying efficiency and environmental compliance, providing reliable material flow guarantees for large-scale production.

The stable operation of screw conveyors relies on a scientifically sound structural design, with each core component working in concert to form a complete conveying system. The screw shaft is the core transmission component of the equipment, welded from screw blades to the shaft body. The helical angle of the blades is precisely designed to ensure a stable pushing force during rotation, driving the material forward. The conveying pipe typically employs a cylindrical structure, serving not only to house the screw shaft and materials but also creating a sealed conveying space. This effectively reduces material leakage and dust emissions, aligning with environmentally friendly production principles. The drive unit, consisting of a motor and a reducer, provides stable rotational power to the screw shaft while adjusting the speed via the reducer to suit different conveying needs. The inlet and outlet handle material entry and exit, respectively, and their positions can be flexibly adjusted according to the conveying angle, ensuring smooth material flow. The support frame provides stable support to the conveying pipe, reducing vibration during operation and ensuring a smooth conveying process. Sealing devices are installed at the inlet, outlet, and other connection points to further enhance the sealing effect, preventing material leakage and the entry of external impurities, ensuring the purity of the conveyed material. The control device enables precise control of equipment start-up and shutdown, as well as conveying speed, making quantitative conveying possible.

The screw conveyor operates on a simple and efficient principle, utilizing the rotational transmission of helical blades to transport materials. During operation, material first enters the sealed conveying pipe through the inlet. Then, the drive unit starts, causing the screw shaft to rotate at a constant speed. The screw blades rotate synchronously, generating axial thrust, which propels the material continuously forward along the conveying direction. When the material is pushed to the outlet, it is discharged from the outlet under the combined action of the pushing force of the screw blades and the material’s own gravity, completing the entire conveying process. The entire process takes place in a sealed environment, ensuring continuous and stable material conveying without much manual intervention, thus improving conveying efficiency and avoiding environmental pollution.

The unique structure and working principle give the screw conveyor many significant advantages, making it adaptable to the complex conveying needs of various industries. Excellent sealing is its core highlight; the sealed conveying pipe design effectively prevents material leakage and dust emission, making it particularly suitable for industries with high environmental requirements, such as chemical and environmental protection. A simple and compact structure is another major advantage. The equipment consists of basic components such as the screw shaft, conveying pipe, and drive unit, occupying a small area and facilitating installation in various production sites. It is also easy to maintain, reducing the operational difficulty for enterprises. Its exceptional adaptability is a key competitive advantage, capable of conveying various powdery, granular, and small lump materials. Whether it’s chemical powders, building material granules, food raw materials, or coal lumps, it can deliver them stably. It also supports multiple conveying angles, including horizontal, inclined, and vertical, flexibly adapting to the layout requirements of different production processes. Operation is remarkably convenient; the conveying speed can be easily adjusted via a control device to achieve quantitative material delivery and precisely match the material needs of subsequent production processes. Furthermore, compared to other types of conveying equipment, screw conveyors have lower energy consumption, and their core components are easy to replace, resulting in low long-term operating and maintenance costs and excellent economic efficiency.

From raw material transfer in chemical workshops to solid waste transportation in environmental protection projects, from raw material proportioning in food factories to material flow in building material enterprises, screw conveyors, with their core advantages of high efficiency, cleanliness, stability, and economy, provide strong support for material conveying in various industries. Against the backdrop of industrial production transforming towards high efficiency and green practices, this simple yet powerful conveying equipment, with its wide adaptability and reliable performance, has become an important basic piece of equipment for promoting the optimization and upgrading of production processes across various industries.

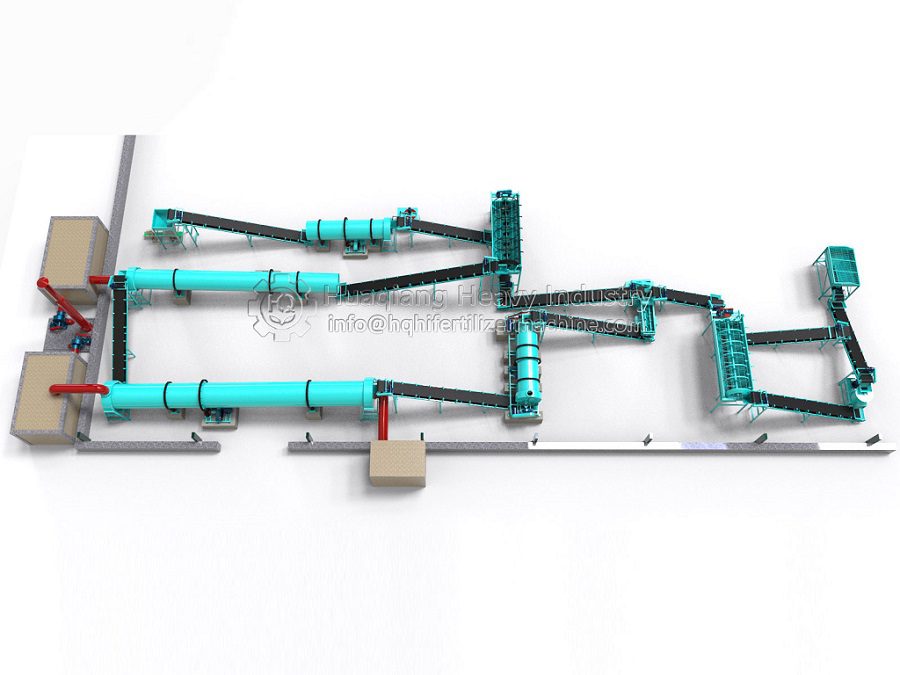

Connecting Process Stages in Modern Organic Systems

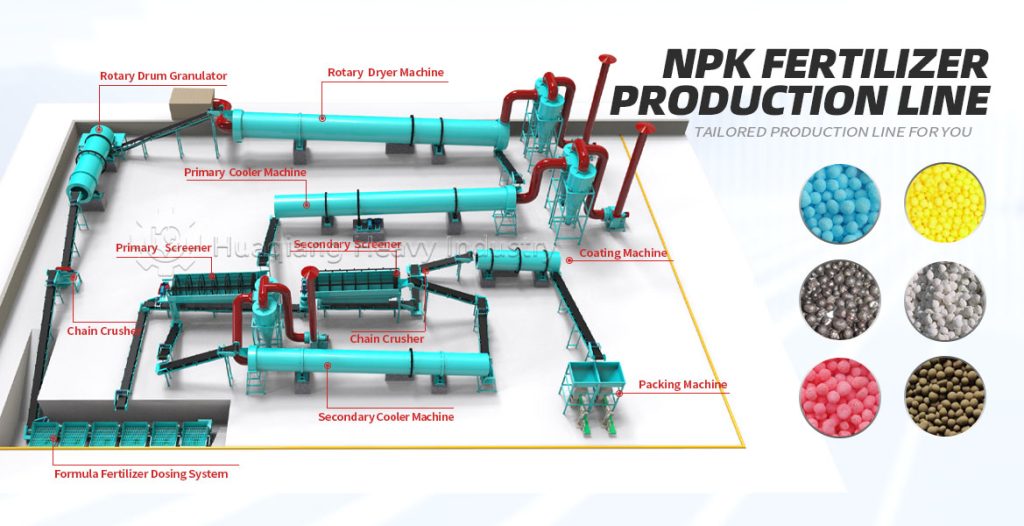

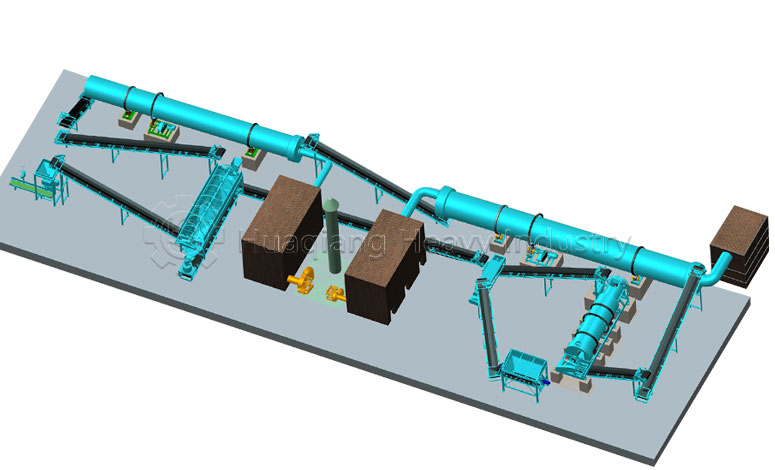

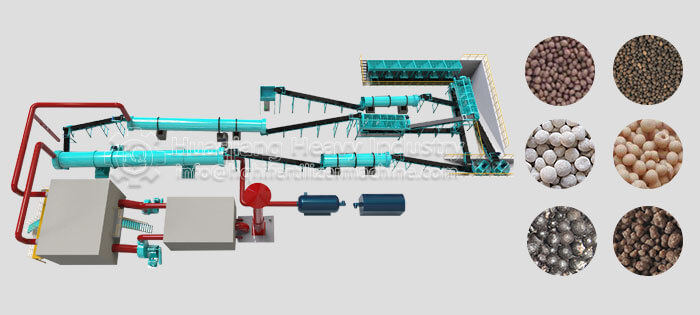

The screw conveyor is an indispensable component within modern, large-scale organic waste processing systems. Its ability to handle powdery and granular materials in a sealed, controlled manner makes it a critical link for moving materials between different stages of a compost production machine operation or a complete fertilizer manufacturing plant.

Within an integrated system, the screw conveyor works in synergy with key pieces of equipments required for biofertilizer production. For example, it can efficiently transfer matured compost from a large wheel compost turner or a chain compost turning machine—core components of fermentation composting technology for organic fertilizer—to a multiple silos single weigh static batching system for precise formulation. It can then convey this blended material to a disc granulation production line for final shaping into pellets. By ensuring a continuous, dust-free flow of material between these major processing units, the screw conveyor enhances the overall efficiency, cleanliness, and automation level of the entire fermentation composting turning technology and production process.Thus, while not a primary processing machine itself, the screw conveyor is a vital enabler of industrial-scale organic fertilizer production, seamlessly connecting biological transformation with mechanical processing to create a continuous, efficient manufacturing flow.