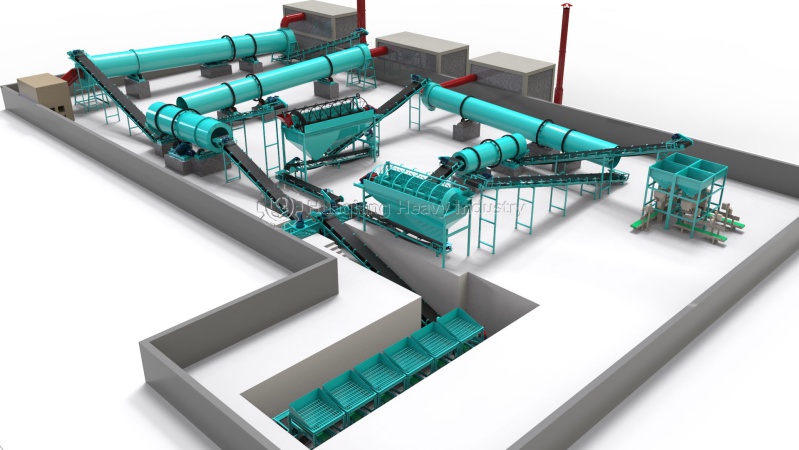

Animal manure fertilizer making equipment processes raw materials into granular organic fertilizers through a series of processes including fermentation, crushing, granulation, drying, cooling, screening, and coating.

Chicken manure, pig manure, cow manure, sludge, etc. are treated harmless through composting and fermentation: Chicken manure and animal manure from breeding farms are mixed with filling materials in a certain proportion, such as straw powder, mushroom residue, medicinal residue, rice bran, grass powder, peanut shell powder, etc. After mixing, organic fertilizer fermentation strains are added, and the mixture is fermented and flipped. The pig manure organic fertilizer production line requires 10-15 days to mature, which can be odorless, odorless, and harmless. The compost is soft and yellow brown in color, There are gray white mycelium and about 45% organic matter in the pile. It has the functions of non-toxic and harmless, increasing yield, improving quality, promoting disease resistance and growth, fertilizing soil fertility, and improving fertilizer utilization. It is an ideal fertilizer for producing green food and developing ecological agriculture.

The characteristics of small livestock and poultry manure organic fertilizer production lines are:

1. Applicability and wide range of raw materials: suitable for direct granulation of fermented animal manure, sugar factory filter sludge, urban sludge, papermaking sludge, distiller’s grains, straw, peat and other coarse fiber organic waste with a moisture content of about 30%. It can produce pure organic fertilizer, organic inorganic fertilizer, and bio organic fertilizer with spherical particles.

2. High ball forming rate and microbial survival rate: The new process can achieve a ball forming rate of over 90-95%, and the low-temperature and high air drying technology can achieve a microbial survival rate of over 90%.

3. The process flow of organic fertilizer production line is short, and the operating cost is low. The organic raw materials used in this process do not require pre-treatment such as drying and crushing. The process flow is short, and the operating cost is low (if traditional granulation processes such as disc or drum are used, the organic raw materials with a moisture content of about 30% after fermentation need to be dried to below 13% and crushed to above 80 mesh, and the amount of organic materials added cannot exceed 30%).