Introduction

With the growing global demand for sustainable agriculture, organic fertilizer production has become a vital component of modern farming. From fermentation to granulation, the process involves multiple key steps that transform organic waste into efficient soil amendments.

Organic Fertilizer Fermentation

Fermentation is the heart of organic fertilizer production line. By controlling temperature, moisture, and aeration, microorganisms break down raw materials such as animal manure and crop residues. This process not only eliminates pathogens but also produces nutrient-rich humus. Modern composting techniques, like trough fermentation and windrow composting, enhance efficiency and reduce environmental impact.

Granulation Process

After fermentation, the material is shaped using an organic fertilizer granulator. Granulation increases the density of the fertilizer, making it easier to store, transport, and apply. Common granulation methods include disc granulation and extrusion, each selected based on raw material properties and end-product requirements.

Complete Production Line

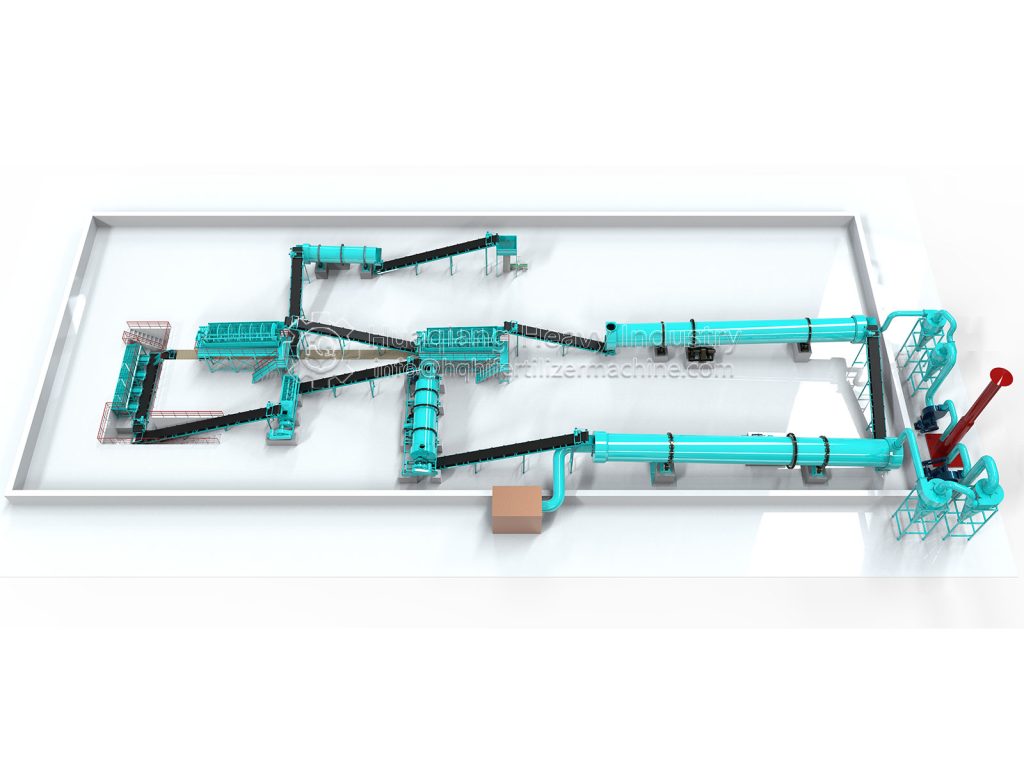

A full organic fertilizer production line integrates equipment for fermentation, crushing, mixing, granulation, drying, cooling, and packaging. This integrated system ensures high-efficiency, large-scale production while maintaining consistent product quality. Production lines can be customized to match the scale of the factory and target market.

Advancements in Composting Technology

Modern composting technologies, such as aerobic fermentation and vermicomposting, accelerate decomposition by optimizing microbial activity. These methods reduce odors, enhance nutrient content, and make organic fertilizers a viable alternative to chemical fertilizers.

Conclusion

From fermentation to granulation, organic fertilizer production turns waste into valuable resources, supporting global sustainable agriculture. By investing in advanced technology and complete production lines, producers can contribute to worldwide food security while promoting environmental stewardship.

The efficiency of modern organic fertilizer production relies heavily on specialized equipment integration. At the core of this system, the organic fertilizer granulator plays a pivotal role in shaping fermented materials into uniform pellets. Prior to granulation, the organic fertilizer fermentation process is optimized using advanced turning equipment. The large wheel compost turner efficiently handles bulk materials in open-air composting sites, while the chain compost turner proves ideal for confined spaces and systematic trough systems. For larger operations, the wheel compost turner offers robust performance with its impressive maneuverability and mixing capacity.

When selecting granulation equipment, the rotary drum granulator stands out for continuous, large-scale production, creating spherical granules through its rotating motion. Similarly, the drum granulator ensures consistent particle size distribution, making it a preferred choice for commercial operations. The complete organic fertilizer production line seamlessly integrates these components, from initial fermentation composting technology for organic fertilizer to final packaging. This integrated approach, combining appropriate fertilizer granulator selection with optimized fermentation composting technology for organic fertilizer, enables producers to transform organic waste into high-value agricultural inputs while maintaining operational efficiency and product quality.

Integrated Technologies: organic fertilizer granulator • large wheel compost turner • chain compost turner • organic fertilizer production line • wheel compost turner • rotary drum granulator • drum granulator • fertilizer granulator • organic fertilizer fermentation • fermentation composting technology for organic fertilizer