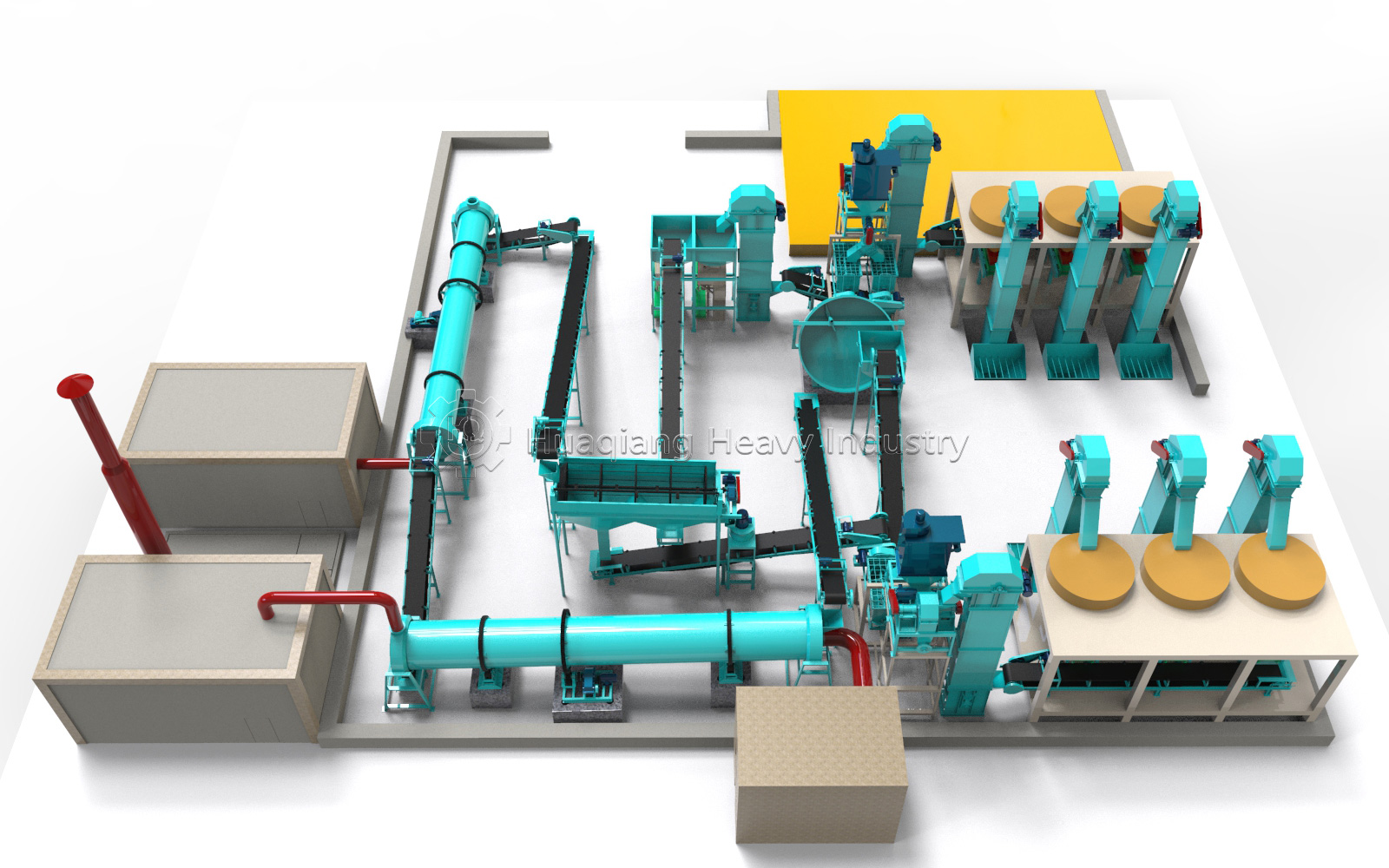

Introduction: A Granulation Powerhouse from Small Workshops to Scale Production

In the production process of organic fertilizers, transforming composted powdered organic raw materials into uniform, regular granules is a crucial step for product commercialization, facilitating storage, transportation, and mechanized application. Among various granulation equipment, the disc granulator, with its unique working principle, wide adaptability, and user-friendly cost, has become one of the most favored granulation devices for small and medium-sized organic fertilizer producers worldwide. It perfectly aligns with the requirements of wet granulation processes. Through a constantly rotating inclined disc, it magically transforms loose organic powder into solid pellets, serving as a vital bridge connecting organic waste resource recovery with modern agricultural application.

I. Working Principle: The Art of “Snowball Rolling” in a Rotating Disc

The working process of a disc granulator is a clever performance combining mechanics and physicochemical reactions. Its core is an inclined disc with a rim (typically adjustable between 30° and 45°), driven to rotate by a motor. Pre-mixed powdered organic fertilizer raw materials (such as composted livestock manure, fermented straw) are continuously and quantitatively fed into the disc.

As the disc rotates, the material begins to move under the combined action of three forces: gravity tends to make it slide downward; centrifugal force tries to throw it towards the rim; and the friction between the disc bottom and the material, as well as between material particles, provides complex tumbling momentum. The most critical step is that while the material is tumbling, water or a specialized binder solution is evenly sprayed onto the material through nozzles installed above the disc. These liquid droplets act as “adhesives,” coating the surface of the powder particles, reducing their surface energy, and forming liquid bridges upon particle collision.

Therefore, the fine powder particles begin to adhere to each other and aggregate, growing gradually around an initial core like a snowball, forming increasingly larger spherical particles. When the particles reach a certain size, the combined force of gravity and centrifugal force is sufficient to overcome the resistance at the edge of the disc, causing them to be “thrown” out of the disc, thus completing the granulation process. Subsequently, these wet “raw” granules need to enter a dryer and cooler to remove excess moisture and lower the temperature, ultimately becoming finished organic fertilizer granules with sufficient strength and acceptable moisture content (usually below 15%).

II. Core Advantages: Why is it Favored by Small and Medium-Sized Manufacturers?

The popularity of disc granulators in the organic fertilizer field stems from a series of outstanding practical advantages:

· Wide Raw Material Adaptability: Whether it’s composted pig manure, chicken manure, cattle manure, biogas residue, fermented straw, or food waste-derived fertilizer, as long as it is pre-processed into a suitable powdered state with controlled initial moisture content (typically 30%-35% is optimal), the disc granulator can process it effectively. Its pelletizing rate for common materials like pig manure can exceed 85%, significantly higher than some other types of granulation equipment.

· Low Cost and Easy Maintenance: The equipment structure is relatively simple, mainly consisting of the disc, drive unit, frame, and spray system, resulting in low initial investment cost and relatively economical operating energy consumption. With few mechanical parts, daily maintenance and cleaning are straightforward, requiring less technical skill from operators, making it ideal for small and medium-sized enterprises or cooperatives with limited capital and manpower.

· Low-Temperature Granulation, Preserving Activity: The entire granulation process occurs at ambient or slightly above ambient temperatures, avoiding the destruction of precious beneficial microbial communities, enzyme activity, and some heat-sensitive organic nutrients in the organic fertilizer, thereby maximizing the preservation of the fertilizer’s biological activity and nutritional value.

· Flexible and Easy to Control: By adjusting the disc’s rotational speed (many devices are equipped with frequency converters) and inclination angle, the residence time and movement trajectory of the material within the disc can be easily changed, effectively controlling the pellet size and density. This provides convenience for producing products of different specifications (e.g., 2-4mm, 4-6mm).

III. Application Challenges and Optimization Directions

Despite its evident advantages, disc granulators also face some challenges in practical application, which need to be addressed through precise operation and equipment improvement:

1. Dust and Working Environment: Due to open or semi-open operation, dust is easily generated during the feeding and initial granulation stages, affecting the workshop environment. Solutions include installing dust collection hoods connected to dust removal systems above the equipment and ensuring the raw material is not overly dry.

2. Pellet Uniformity Control: Compared to some high-pressure granulation equipment, disc granulators offer slightly less precision in controlling pellet size uniformity. This highly depends on operational experience, requiring precise regulation of multiple parameters such as raw material moisture content, binder addition rate, disc speed, and inclination angle. The introduction of automated control systems and online monitoring equipment helps stabilize product quality.

3. Wall Sticking Issues: When processing certain organic raw materials with high viscosity, the material tends to stick to the bottom of the disc, affecting pellet formation and discharge. Modern improved equipment often lines the inner wall of the disc with wear-resistant, anti-stick rubber or polymer lining plates and designs scraper devices to effectively mitigate this problem.

4. Lower Pellet Density: Pellets made by the rolling method typically have lower density and slightly lower hardness than those made by extrusion. While this benefits pellet disintegration in soil, it may also increase breakage rates during transportation. This can be improved by optimizing the formulation (e.g., adding appropriate mineral additives) and post-processing techniques (e.g., moderately increasing drying temperature).

Choosing the Right Granulation Path: Wet Shaping vs. Dry Compaction

The disc granulator is a cornerstone of wet granulation, specifically designed for disc granulator for shaping spherical pellets in processes like a disc granulation production line. Its gentle, rolling action is ideal for organic materials and contrasts with methods used in the standard npk manufacturing process, which often employs a rotary drum granulator for large-scale wet granulation or completely different technology for dry processes.

For dry granulation, the principle is fertilizer granules compaction, which utilizes a fertilizer compaction machine (also known as a fertilizer compactor). This equipment forms the core of a roller press granulator production line, applying high pressure to powders without binders. The choice between a disc granulator for wet shaping and a roller press for dry compaction depends on raw material properties, desired product characteristics, and production scale, highlighting the diverse technological options available in modern fertilizer manufacturing.

Conclusion

In summary, with its intuitive principle, strong adaptability, and high return on investment, the disc granulator holds an irreplaceable position in the global organic fertilizer industry, particularly in small and medium-scale production. It successfully transforms seemingly insignificant organic waste into standardized, commercialized agricultural inputs. With continuous technological improvements, such as the integration of better anti-stick materials, more intelligent control systems, and more efficient dust removal solutions, disc granulators will continue to enhance their performance and environmental standards, providing solid and reliable technical equipment support for the resource recovery cycle of organic waste and the development of sustainable agriculture.