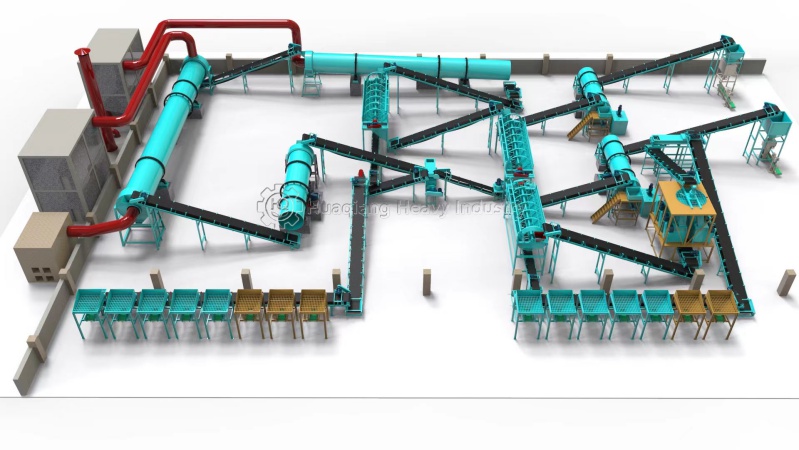

The organic fertilizer production equipment is composed of organic fertilizer fermentation flipping machine, fertilizer crusher, mixer, organic fertilizer granulator, organic fertilizer dryer, cooling machine, screening machine, storage bin, automatic packaging machine, belt conveyor and other equipment. Processing organic materials such as animal manure, straw and rice husks, biogas sludge, kitchen waste, and urban waste into organic fertilizers can not only reduce environmental pollution but also turn waste into treasure.

The process flow of small-scale organic fertilizer production equipment is as follows: after the fermentation of organic fertilizer raw materials (animal manure, household waste, dead branches and leaves, biogas residue, waste bacterial strains, etc.), they enter a semi wet material crusher for crushing, and then add elements such as nitrogen, phosphorus and potassium (pure nitrogen, phosphorus pentoxide, potassium chloride, ammonium chloride, etc.) to meet the required standards of mineral elements. Then, a mixer is used for stirring, and the particles enter the granulation mechanism. After coming out, they are dried, Through the screening machine, qualified products are packaged.

Organic fertilizer processing equipment has different equipment configurations based on different raw materials, and suitable plans can also be made according to investment budgets. The prices of organic fertilizer processing equipment vary with different yields. Firstly, it is necessary to consider the amount of organic fertilizer production that you want to invest in, and then inform the manufacturer of the raw materials used for processing and production. This will provide an approximate price range for everyone, and then select the appropriate production line configuration based on the expected investment.