In modern agriculture, the NPK fertilizer manufacturing process represents a perfect marriage of science and engineering. This intricate yet efficient production method combines nitrogen (N), phosphorus (P), and potassium (K) into balanced plant nutrition.

Raw Material Preparation: The First Step in NPK Production

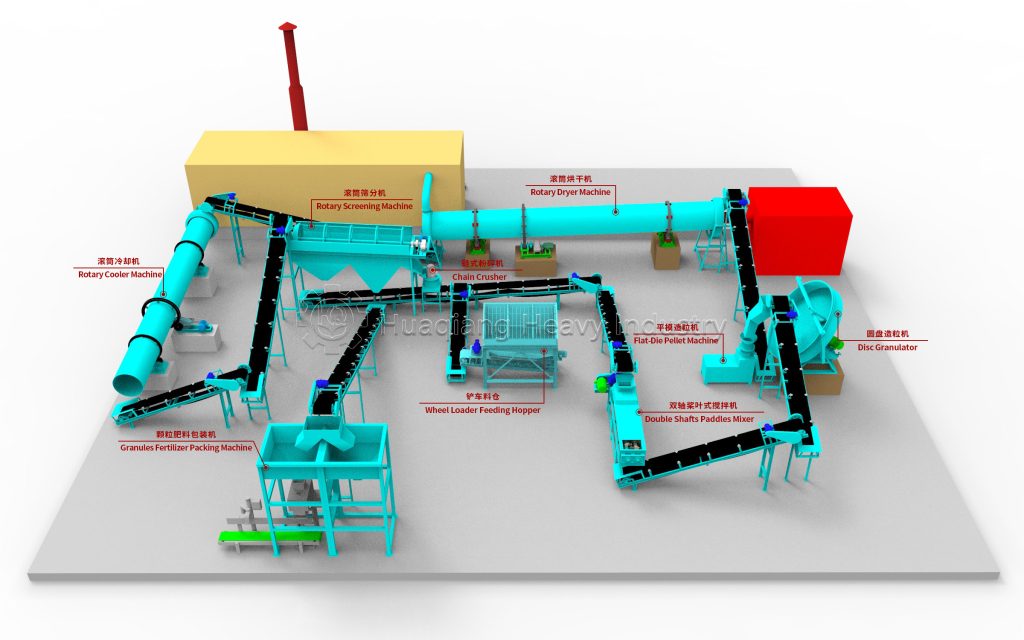

The NPK compound fertilizer production process begins with meticulous raw material screening. Various base fertilizers are separately sieved, then crushed and screened again. The screened materials are fed into corresponding hoppers. This preprocessing ensures uniformity and reactivity of materials for subsequent NPK manufacturing stages.

Precise Formulation: The Heart of Compound Fertilizer Production

On the NPK production production line, each base fertilizer is precisely measured and conveyed from individual hoppers to a mixing hopper. Simultaneously, recycled materials join the base fertilizers through lifting equipment. During transportation, initial mixing occurs. The blended materials are then fed into the granulator at controlled rates.

The Granulation Magic: Pivotal Stage in NPK Fertilizer Production

The granulator stands as the most critical equipment in NPK fertilizer manufacturing. As materials enter the rotating drum granulator, saturated steam introduced beneath the material bed performs dual functions – heating and moistening the mixture. When necessary, water or fertilizer solution is sprayed to maintain optimal moisture for granulation.

Featuring special rubber or acid-resistant stainless steel linings, the drum granulator facilitates particle formation through friction and compression. During NPK production, steam, ammonia gas, phosphoric acid, nitrogen solutions, or ammonium phosphate slurry work synergistically to create granules through chemical and mechanical action.

Refinement: From Granules to Finished Product

Freshly formed NPK fertilizer granules proceed to drying, followed by screening, cooling, packaging, and storage. Off-spec particles are crushed and recycled with screen undersize materials back into the NPK manufacturing process. This closed-loop design maximizes material utilization while ensuring consistent product quality.

The entire NPK compound fertilizer production process embodies modern industrial precision and circular economy principles. Each step from raw materials to finished product undergoes meticulous design and strict control, ultimately delivering efficient, balanced nutrition solutions for modern agriculture.