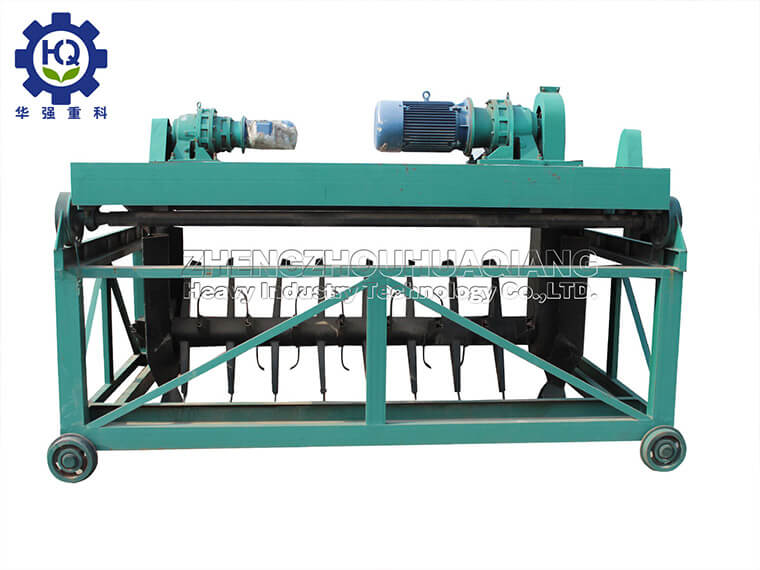

The trough type organic fertilizer turning machine is a mechanical equipment designed specifically for large-scale composting production. It accelerates the anaerobic or aerobic fermentation process of organic waste through mechanical turning and mixing, and is suitable for treating various organic wastes, including kitchen waste. The following are the basic steps for using a trough type turning machine to ferment kitchen waste into fertilizer:

preparation

Classification and pretreatment: Sort kitchen waste and remove non biodegradable materials such as plastics and metals. Cut or crush food residues as needed to increase surface contact area and accelerate decomposition.

Adding auxiliary materials: Adding materials with strong adsorption properties such as sawdust, rice husks, and wheat straw, as well as coarse fiber materials such as sawdust and leaves, to adjust the carbon to nitrogen ratio (C/N ratio) to close to 30:1, which is beneficial for microbial growth. Mixing fermentation agents, such as EM bacteria, to accelerate the fermentation process.

fermentation process

Filling: Evenly lay the processed kitchen waste and its auxiliary materials in the pre built fermentation tank, forming a stack of a certain height and width.

Ventilation: Install ventilation pipes or use the built-in fan system of the trough type reactor to ensure oxygen supply inside the reactor and support aerobic fermentation.

Pile turning: Use a trough type turning machine to regularly turn the pile, evenly disperse the heat source inside the pile, provide fresh oxygen, promote microbial activity, and prevent excessive local heating from causing odor and toxic gases in anaerobic environments.

Monitoring: Monitor temperature, humidity, and pH values, adjust as necessary, and maintain suitable fermentation conditions.

Maturity and post-processing

Check maturity: When the temperature of the heap begins to steadily decrease and no longer rise, and the material appears dark brown or black with a soft texture, it indicates that fermentation is basically complete.

Aging: The fermented material needs to be aged for a period of time to further decompose the remaining organic matter and improve the stability and efficiency of the fertilizer.

Crushing and screening: Mature fertilizers are crushed by a grinder, and qualified fertilizer particles are screened through a sieve to remove lumps of non ideal size.

Packaging and Storage: Finally, the finished organic fertilizer is packaged in bags and stored in a dry and ventilated place until it is sold or used.

The use of trough type composting machines greatly improves the efficiency of converting kitchen waste into organic fertilizers, reducing the burden on the environment and generating valuable resources, promoting the development of circular economy.