Overview of Granular Fertilizer Production

Granular fertilizer production is a complex process that transforms powdered, liquid, or semi-solid raw materials into granular products with specific particle sizes, strength, and stability. This process not only improves the physical characteristics of fertilizers for easier storage and application but also enhances nutrient utilization efficiency. Modern granular fertilizer production has developed a complete process system covering all stages from raw material pretreatment to final packaging.

Whether for organic fertilizers, chemical fertilizers, or compound fertilizers, the granulation production process follows similar principles, but there are significant differences in specific technical parameters and equipment selection. Understanding these differences is crucial for optimizing production processes and improving product quality.

Core Production Process

Raw Material Pretreatment

Raw material pretreatment is the fundamental step to ensure granular quality. Solid materials need to be crushed to 80-100 mesh fineness to ensure uniformity in subsequent granulation. For organic fertilizers, thorough fermentation and maturation must first be completed to eliminate pathogens and insect eggs while controlling moisture within appropriate ranges. Precise material proportioning and thorough mixing are also key tasks at this stage.

Granulation and Forming

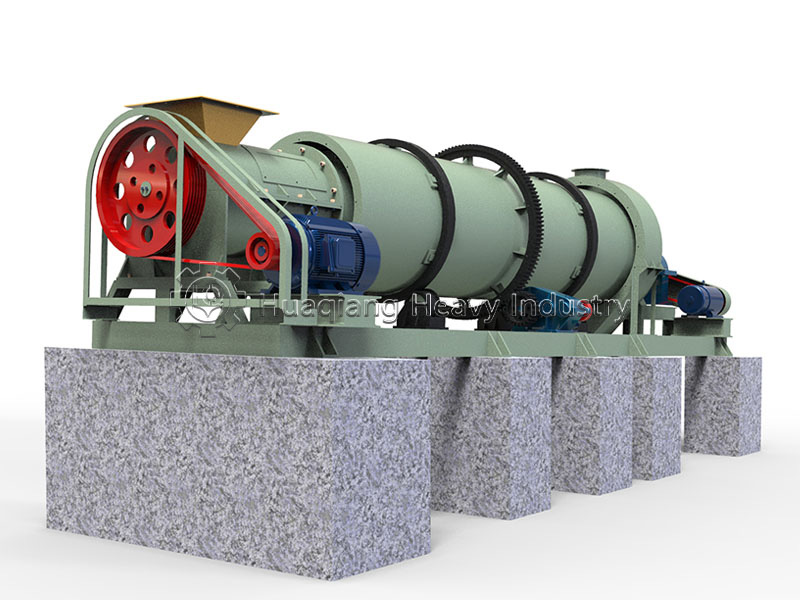

Granulation is the core process in granular fertilizer production. Depending on material characteristics and product requirements, different granulation methods can be selected, including disc granulation, drum granulation, and extrusion granulation. Disc granulation is suitable for small to medium-scale production with simple equipment and flexible operation; drum granulation fits large-scale continuous production with high automation; extrusion granulation is particularly suitable for low-moisture materials without requiring binders.

Drying and Screening

After granulation, wet granules need to undergo drying to reduce moisture to safe storage levels. Control of drying temperature is particularly important, as excessive temperatures can cause nutrient loss, especially for organic fertilizers. The screening process ensures uniform particle size distribution, with non-conforming granules being reprocessed to improve raw material utilization.

Production Characteristics of Different Granular Fertilizers

Organic Granular Fertilizer

The production of organic granular fertilizers places special emphasis on thorough maturation of raw materials and fineness of crushing. Since organic materials typically have high moisture content and poor viscosity, appropriate amounts of binders need to be added to improve granulation performance. Low-temperature drying is key to protecting organic matter activity, with drying temperatures usually controlled below 120°C.

Chemical Granular Fertilizer

Chemical granular fertilizer production focuses more on precise material proportioning and control of granulation pressure. Drum granulation and extrusion granulation are commonly used methods, with steam regulation improving material viscosity. High-temperature drying can rapidly reduce moisture content but requires strict temperature control to avoid nutrient decomposition.

Organic-Inorganic Compound Granular Fertilizer

Production of this type of fertilizer requires balancing the characteristics of organic and chemical fertilizers, ensuring mixing uniformity and avoiding nutrient antagonism. Pelletizing granulation can form stable granular structures, while medium-temperature drying both protects organic matter and ensures drying effectiveness.

Production Scale and Equipment Selection

The production scale of granular fertilizers directly affects equipment configuration and process selection. Small-scale production suits equipment with strong flexibility and low investment like disc granulators, while large-scale industrial production requires highly automated drum granulation or spray granulation production lines. Regardless of scale, equipment must meet product quality requirements and environmental standards.

Successful granular fertilizer production requires comprehensive consideration of material characteristics, product requirements, production scale, and cost-effectiveness. By optimizing process parameters and selecting appropriate equipment, producers can manufacture high-quality granular fertilizer products that meet agricultural needs while maintaining good economic benefits.

Advanced Technologies in Modern Granular Fertilizer Production

The comprehensive process of granular fertilizer production integrates multiple advanced technologies to transform raw materials into high-quality agricultural inputs. In npk fertilizer production process systems, the rotary drum granulator plays a crucial role in large-scale continuous operations, utilizing drum granulation principles to create uniform particles. Meanwhile, the roller press granulator production line offers an alternative approach through fertilizer granules compaction, particularly suitable for materials requiring dry processing without binders.

For organic fertilizer production, the process begins with advanced fermentation composting technology for organic fertilizer, often utilizing windrow composting machine equipment to prepare raw materials. The innovative new type two in one organic fertilizer granulator then combines multiple processing stages, streamlining production while maintaining product quality. These technologies represent significant advancements in npk fertilizer production technology, enabling manufacturers to optimize their npk production line configurations for specific market requirements.

Whether employing drum granulator systems for wet granulation or specialized fertilizer compaction machine units for dry processing, modern fertilizer production has evolved to offer diverse solutions across the complete npk manufacturing process. From the basic rotary granulator to sophisticated integrated lines, these technologies continue to drive efficiency and quality improvements in granular fertilizer manufacturing, supporting sustainable agricultural practices worldwide.