The manure produced by livestock and poultry breeding, such as pig manure, cow manure, sheep manure, chicken manure and other animal manure, will have a bad impact on the environment if it is not handled well. Using the new production technology of organic fertilizer production equipment, the manure is directly treated into organic fertilizer, and straw manure is turned into feed. Such a recycling fertilizer production line can solve many problems caused by livestock manure.

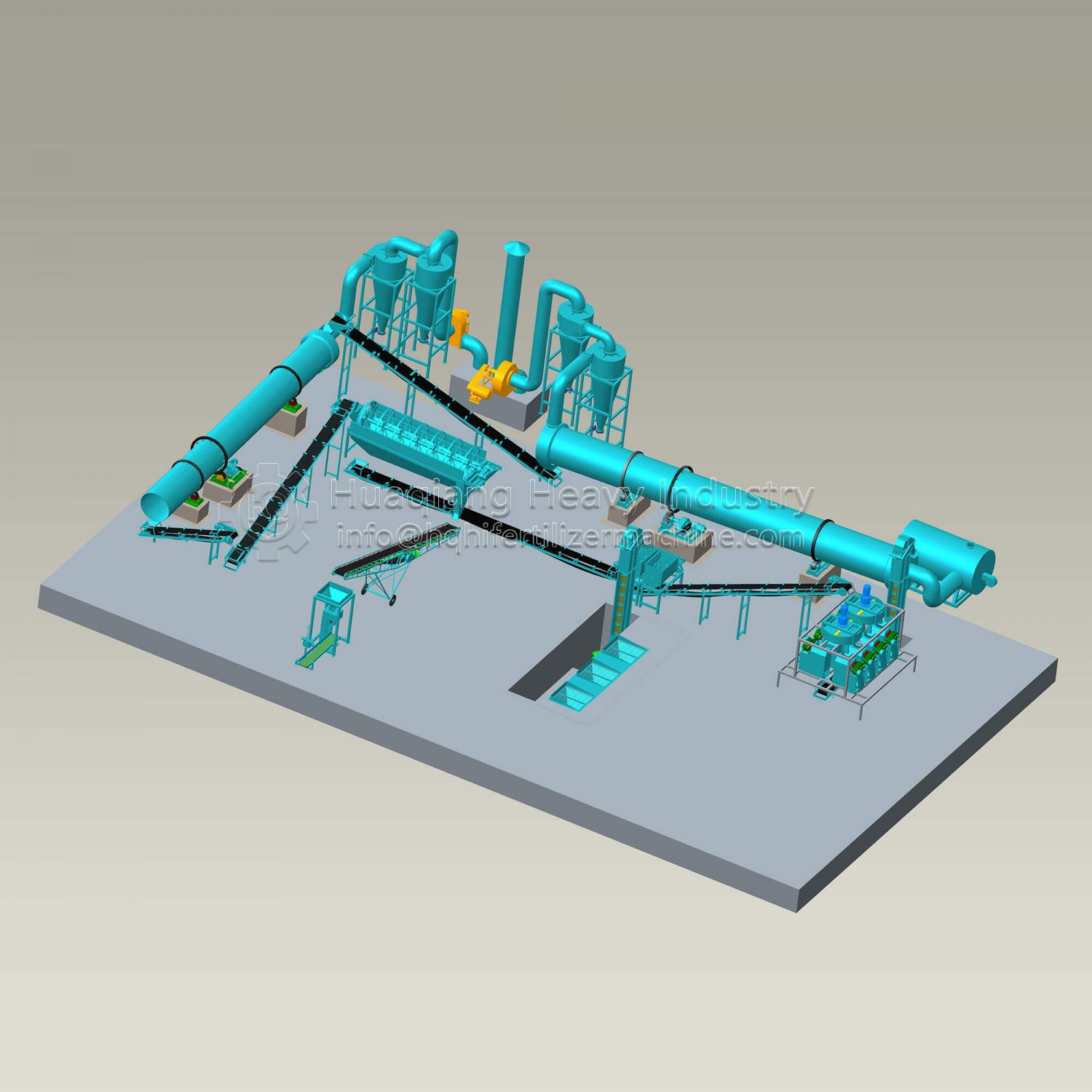

It is a very promising project to use organic fertilizer production line to process animal manure into organic fertilizer. The general process of processing organic fertilizer granules consists of fermentation, turning, grinding, stirring, granulation, drying and cooling. The production line of powdered organic fertilizer only needs fermentation, turning over, crushing and mixing process, and the fertilizer can be packaged and sold without heavy equipment such as rotary drum granulator, dryer and cooler.

The organic fertilizer production line can be divided into static processing and dynamic processing. Enterprises can reasonably arrange production according to different manure sources, site size and fertilizer demand. It is suggested that static processing should be adopted to produce organic fertilizer, which is less investment, simple method and easy operation.

Fertilizer granulator machine price is low and the granule produced is spherical. It is a very practical and widely used fertilizer granulation equipment. Organic fertilizer granulator makes use of organic matter particles under a certain force to inlay and grow up with each other, so there is no need to add binder when granulating. The organic matter after fermentation does not need to be dried, which reduces the energy consumption of drying. The fertilizer has high organic matter content and solid particles, which can be sieved after granulation.