With the advancement of green agricultural development, market demand for bio-organic fertilizer continues to rise due to its advantages in improving soil quality and enhancing crop quality. Establishing an efficient and compliant bio-organic fertilizer production line requires a comprehensive approach, from planning to operational systems.

Preliminary preparation is the foundation. Production capacity should be determined based on the regional agricultural scale and raw material supply capacity. A daily output of 50-100 tons for small-scale lines and 100-300 tons for medium-sized lines is appropriate. Simultaneously, procedures such as obtaining a business license and environmental impact assessment approval should be obtained, with a focus on improving waste gas and wastewater treatment solutions for the fermentation process. On the raw material side, collaboration can be conducted with farms and agricultural product processing companies to ensure the supply of livestock and poultry manure, straw, and other materials. Simultaneously, a testing mechanism should be established to ensure that raw materials meet national standards.

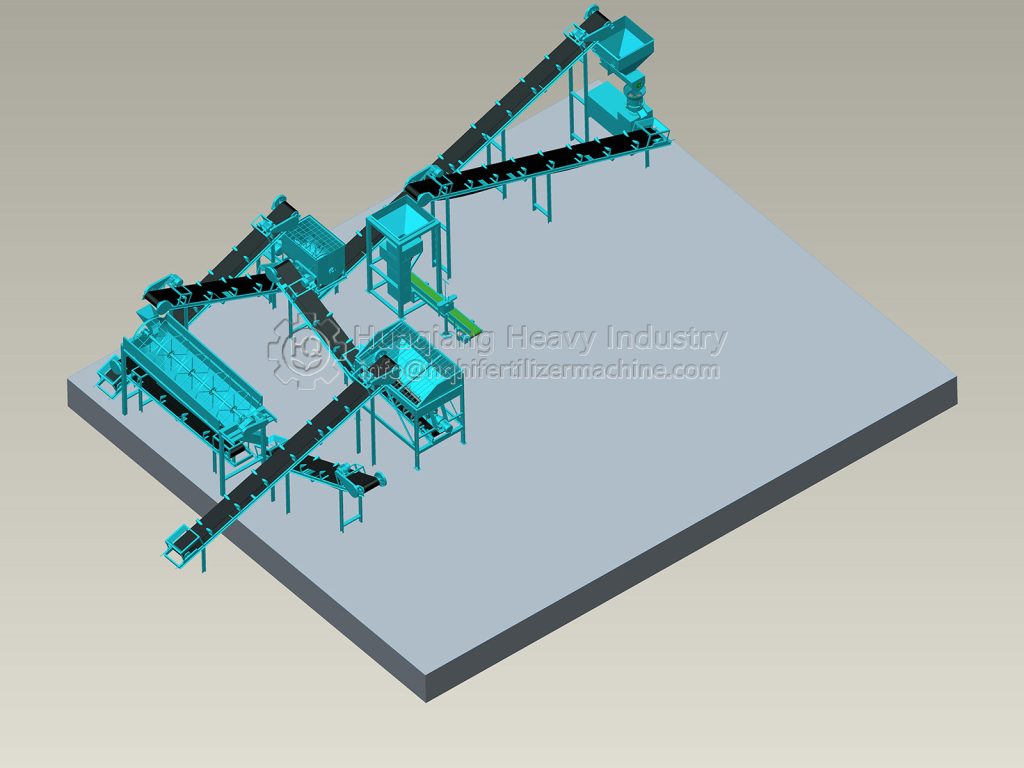

Core equipment configuration determines production efficiency. Pretreatment requires a crusher and screener to break the raw materials into uniform particles. Fermentation equipment should be selected based on scale. For small and medium-sized plants, a trough-type turner should be used. Control the temperature at 55-65°C and the humidity at 50%-60% to accelerate composting. Subsequent equipment requires a mixer, granulator, dryer, cooler, and packaging machine. When selecting equipment, consider both production capacity and energy conservation and environmental protection, prioritizing low-energy, highly automated equipment to reduce labor costs.

Control of the production process directly impacts product quality. During pretreatment, microbial strains should be added proportionally to adjust the carbon-nitrogen ratio to 25:1-30:1. During the fermentation phase, temperature should be strictly monitored to ensure a 7-15 day composting cycle and prevent root burn. Finished products must be tested for moisture (≤30%) and organic matter (≥45%), and only qualified products can be shipped. Furthermore, a production log should be established to ensure quality traceability.

Production line operations must prioritize both market and technology. We can cooperate with agricultural cooperatives and large-scale growers to provide sample trials and technical guidance; at the same time, we pay attention to industry trends, introduce intelligent monitoring systems, adjust parameters in real time, and improve the stability of the bio-organic fertilizer production line and product competitiveness.