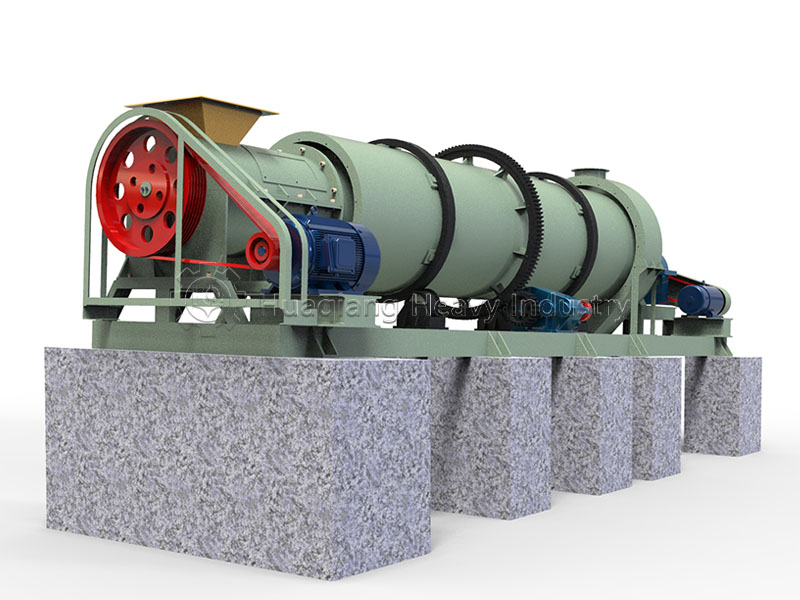

In the era of green agriculture, the New Type Two-In-One Organic Fertilizer Granulator has emerged as a revolutionary organic fertilizer production machine, combining mixing and granulation processes to transform organic waste into valuable resources.

Unlike conventional rotary drum granulators, this innovative organic fertilizer manufacturing machine integrates stirring teeth within the drum, enhancing material agitation and creating more uniform granules with higher sphericity and compressive strength.

Compared to traditional fertilizer granules compaction methods, the New Type Stirring Tooth-Drum Granulator operates without binders, producing organic fertilizer through a wet granulation process that preserves nutrient integrity while reducing energy consumption.

This dual-function organic fertilizer production machine represents a significant advancement in sustainable agriculture technology, offering superior efficiency and product quality for modern organic fertilizer manufacturing operations worldwide.

Wide Applications: Green Transformation from Farms to Cities

Large-scale Organic Fertilizer Production

The preferred equipment for large organic fertilizer plants and processing cooperatives, capable of meeting organic fertilizer granulation needs at different scales. The produced granular organic fertilizers are widely used in farmland, orchards, vegetable bases, and flower cultivation.

Organic-Inorganic Compound Fertilizers

In organic-inorganic compound fertilizer production, it handles the pretreatment and granulation of the organic portion, providing key technical support for producing compound fertilizers that combine the advantages of both organic and inorganic fertilizers.

Bio-organic Fertilizer Manufacturing

Better preserves the activity of beneficial microorganisms during the granulation process, ensuring the functionality of bio-organic fertilizers, making it an ideal choice for producing high-quality bio-organic fertilizers.

Diverse Raw Material Processing Capability

· Livestock Manure – Various animal excrements including chicken, pig, and cattle manure

· Agricultural Waste – Crop straws, mushroom residues, distiller’s grains, vinegar residues

· Municipal Waste – Municipal sludge and other urban organic waste

· Other Organic Materials – Various fermentable organic raw materials

Exquisite Design: Perfect Fusion of Technology and Innovation

Intelligent Mixing System

Utilizes high-strength alloy steel mixing shafts with spiral or paddle-type wear-resistant mixing blades, driven by variable frequency motors with adjustable speeds of 20-60 rpm, ensuring mixing uniformity of over 90%.

Efficient Granulation System

Granulation disc angle hydraulically adjustable (30°-50°), featuring stainless steel base with wear-resistant rubber lining, equipped with various forming mechanisms including stirring tooth type and roller type to meet different material characteristics.

Precision Control System

PLC touchscreen control system monitors parameters such as mixing time, granulation speed, and material moisture in real-time, equipped with sensors for automatic alarms, achieving intelligent production management.

Automated Feeding & Discharge

Hopper equipped with level sensors, variable frequency speed regulation for screw feeders, discharge device with vibration anti-blocking mechanism, ensuring smooth production flow.

Particularly noteworthy is the equipment’s modular design concept, which gives it excellent adaptability. Whether processing viscous livestock manure or loose crop straws, optimal granulation results can be achieved by adjusting process parameters. This flexibility makes the dual-function granulator an ideal choice for various organic fertilizer production enterprises.

Technical Advantages: Redefining Production Efficiency

The most significant advantage of the dual-function granulator lies in its highly integrated design. The mixing and granulation processes that traditionally required multiple pieces of equipment can now be perfectly accomplished with just one machine. This not only significantly reduces equipment footprint but also markedly decreases energy consumption and labor costs. Meanwhile, the enclosed design effectively prevents dust pollution, creating a more environmentally friendly production environment.

The new dual-function organic fertilizer granulator represents not only outstanding technological innovation but also an important force driving sustainable agricultural development. With its wide raw material adaptability, exquisite process design, and exceptional production efficiency, it is playing an irreplaceable role in the global organic fertilizer production sector. From farms to cities, from traditional agriculture to modern circular agriculture, this equipment is contributing significantly to building a greener, more sustainable agricultural production system in its unique way.