With the global emphasis on sustainable agriculture and ecological protection, the organic fertilizer industry has developed rapidly, and the organic fertilizer production line and organic fertilizer manufacturing system have become the core infrastructure for realizing large-scale, standardized organic fertilizer production. These integrated systems convert agricultural wastes, animal manure, and organic residues into high-quality organic fertilizer through scientific processes, realizing resource recycling while improving soil fertility. Among them, organic fertilizer production granulation is a key link that determines the quality and application effect of the final product, and the organic fertilizer disc granulation machine and organic fertilizer combined granulation production line are widely used in the industry due to their stable performance and high efficiency.

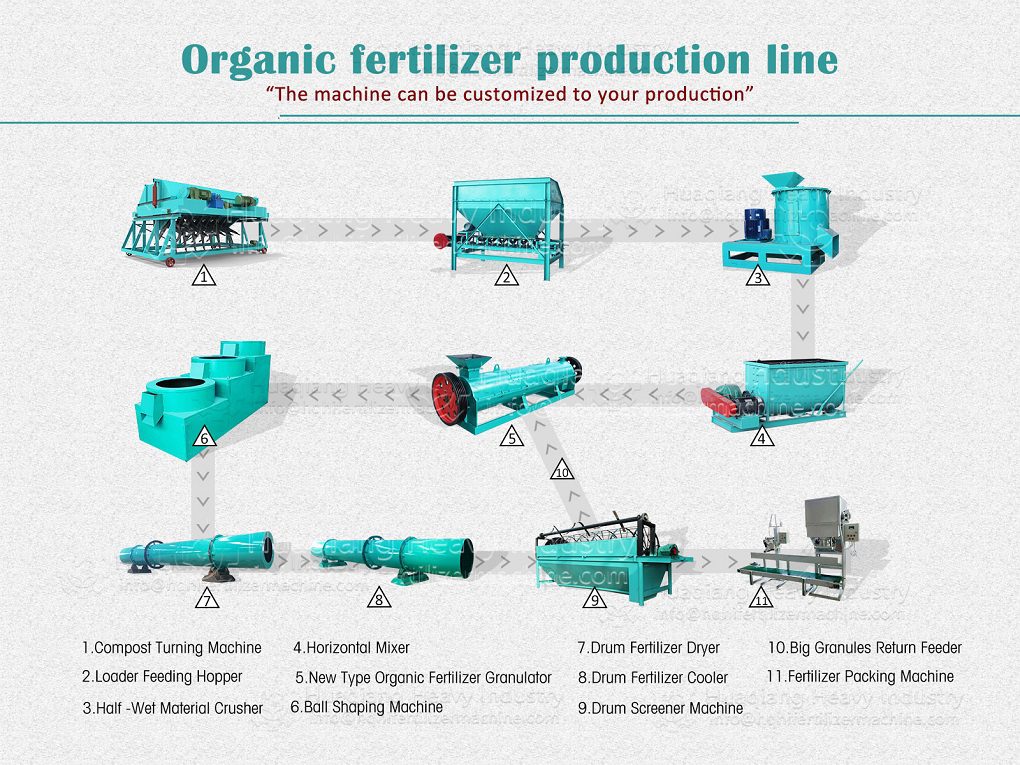

An organic fertilizer manufacturing system is a comprehensive assembly of multiple processes and equipment, covering raw material pretreatment, fermentation, granulation, drying, cooling, screening, packaging, and other links. The entire system is designed to ensure the continuous and efficient operation of the production process, from the initial collection and crushing of organic raw materials to the final formation of finished fertilizer. Raw materials such as crop straw, poultry manure, and kitchen waste need to go through high-temperature composting fermentation first to eliminate pathogens and odors, and convert unstable organic matter into stable nutrients. After fermentation, the material enters the organic fertilizer production granulation stage, which is the core of the entire production line, as granular fertilizer is easier to store, transport, and apply uniformly than powdery fertilizer.

The organic fertilizer disc granulation machine is one of the most mature and widely used equipment in organic fertilizer production granulation. This machine adopts an inclined rotating disc structure, and the fermented organic material is fed into the disc. With the rotation of the disc, the material forms spherical granules under the combined action of its own gravity and appropriate liquid binder. The disc granulation machine has the advantages of simple structure, convenient operation, and high granulation rate, and is especially suitable for small and medium-sized organic fertilizer production lines. It can flexibly adjust the rotating speed and inclination angle of the disc according to the characteristics of the material and the required granule size, ensuring the uniformity and roundness of the granules, which lays a good foundation for the subsequent drying and screening processes.

For large-scale production enterprises with higher efficiency and automation requirements, the organic fertilizer combined granulation production line has become the first choice. This integrated production line integrates multiple processes such as mixing, granulation, drying, cooling, and screening, and realizes automated continuous production. Different from a single disc granulation machine, the combined granulation production line can adopt a variety of granulation technologies according to production needs, such as combining disc granulation with stirring-tooth granulation, which not only improves the granulation efficiency but also optimizes the quality of the granules. The production line is equipped with intelligent control systems, which can accurately adjust parameters such as material ratio, moisture content, and granulation speed, ensuring stable product quality and reducing manual operation errors.

In the organic fertilizer production granulation process, whether using a single disc granulation machine or an integrated combined granulation production line, the selection of equipment needs to be based on factors such as production scale, raw material characteristics, and product requirements. For small-scale farms or local processing plants, the disc granulation machine is cost-effective and easy to maintain, which can meet basic production needs. For large-scale industrial production, the combined granulation production line has obvious advantages in efficiency, automation, and product consistency, which can help enterprises reduce production costs and improve market competitiveness.

The continuous optimization and upgrading of the organic fertilizer production line and organic fertilizer manufacturing system have promoted the high-quality development of the organic fertilizer industry. These production systems not only solve the problem of environmental pollution caused by organic waste but also provide high-quality organic fertilizer for agriculture, helping to improve soil structure, increase crop yield, and ensure food safety. As the concept of ecological agriculture deepens, the demand for efficient, energy-saving, and intelligent organic fertilizer production lines will continue to grow, and the organic fertilizer disc granulation machine and combined granulation production line will be further improved in technology, contributing more to the development of sustainable agriculture.