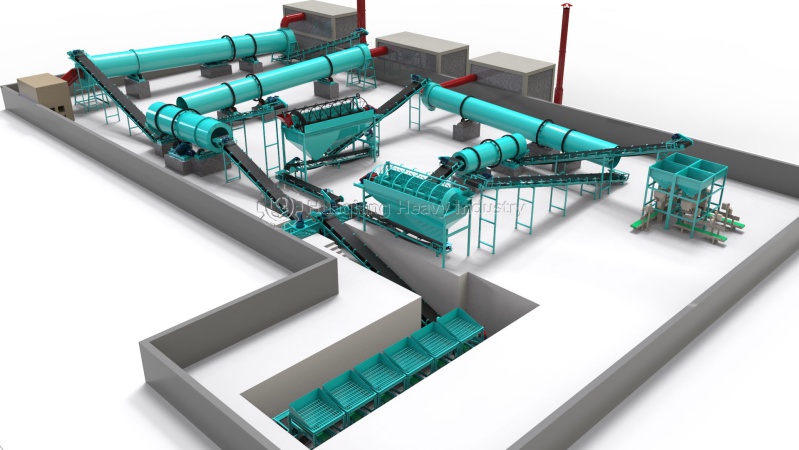

The organic liquid fertilizer production line is a modern production line specifically designed for producing organic liquid fertilizers. This production line usually covers multiple stages such as raw material collection, pretreatment, fermentation, mixing, reaction, filtration, storage, and filling, aiming to convert organic raw materials into efficient and environmentally friendly liquid fertilizers.

Main features:

Diverse raw materials: The organic liquid fertilizer production line can accept various organic raw materials, such as animal and plant residues, waste, crop straw, etc., and convert them into valuable liquid fertilizers through scientific processes.

Efficient fermentation: The fermentation process in the fertilizer production line adopts advanced microbial fermentation technology, which promotes the proliferation of beneficial microorganisms by controlling environmental conditions such as temperature, humidity, and oxygen, and converts organic raw materials into nutrient rich liquid fertilizers.

High degree of automation: The entire production line adopts a computer control system to achieve automated production, packaging, and transportation, greatly improving production efficiency and reducing labor costs.

Stable product quality: Due to automation control, various production processes can be precisely controlled to ensure stable product quality and meet the needs of crop growth.

Environmental protection and energy conservation: The waste and wastewater generated during the production process can be recycled after treatment, reducing environmental pollution. Meanwhile, the production line adopts energy-saving equipment and technology to reduce energy consumption.

Main equipment:

Pre processing equipment: used for crushing, screening, and other preliminary processing of raw materials for subsequent processing.

Fermentation equipment: such as fermentation tanks, used for microbial fermentation to convert organic raw materials into liquid fertilizers.

Mixing and reaction equipment: used to mix fermented liquid with additives, etc., and further improve the quality of fertilizers through specific chemical reactions.

Filtering and storage equipment: Filtering equipment is used to remove impurities from liquid fertilizers and ensure product quality; The storage equipment is used to temporarily store liquid fertilizers for subsequent filling.

Filling and packaging equipment: used to fill liquid fertilizers into designated containers and seal them for easy transportation and use.

Application prospects:

With the development of modern agriculture and the increasing demand for environmental protection, organic liquid fertilizers have received increasing attention due to their high efficiency, environmental protection, and easy absorption. As a key equipment for producing this type of fertilizer, the organic liquid fertilizer production line has broad market prospects. In the future, with continuous technological innovation and market expansion, organic liquid fertilizer production lines will become more intelligent and efficient, providing higher quality fertilizer products for agricultural production.

In short, the organic liquid fertilizer production line is a modern production line that integrates multiple links such as raw material treatment, fermentation, mixing, filtration, storage, and filling. It has the characteristics of high efficiency, environmental protection, and high degree of automation, providing strong support for agricultural production.

.jpg)