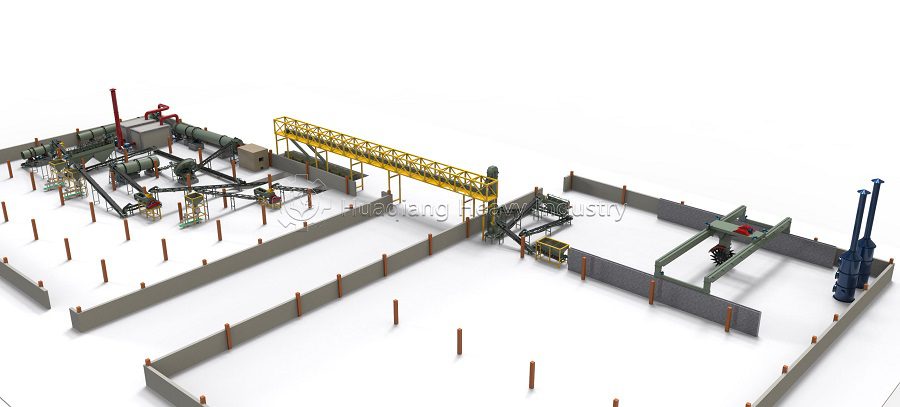

A Granulation Production Line Successfully Deployed in Zambia

Zhengzhou Huaqiang Heavy Industry Technology Co., Ltd. has successfully completed the installation and commissioning of a customized extrusion granulation production line for its Zambian clients, officially entering the stage of large-scale production. This production line focuses on the localized production needs of compound fertilizers and organic fertilizers, integrating the entire chain of processes including raw material pretreatment, precise mixing, efficient granulation, grading and screening, and finished product packaging. With its robust configuration of three granulation main units operating in tandem, stable design adapted to African conditions, and efficient and environmentally friendly operation, it has become a benchmark project for Chinese agricultural equipment in supporting the development of green agriculture in Africa, providing Zambian fertilizer producers with a one-stop mass production solution.

Production Line Configuration and Core Equipment Analysis

The entire production line follows a closed-loop logic of “refined raw material processing – uniform mixing – batch granulation – quality control – finished product output.” The equipment layout is scientific, the connections are tight, and the functions of each unit are complementary, ensuring both production efficiency and full adaptation to the characteristics of local raw materials and production conditions in Zambia.

Raw Material Pretreatment Unit: Laying a Solid Foundation for Granulation Quality

Raw Material Feeding and Crushing: The production line starts with a large-capacity feed hopper, adapting to the rapid feeding needs of bulk raw materials. The feed inlet is equipped with a spill-proof buffer device and an impurity filter grid, effectively reducing raw material loss and equipment failure risks. Raw materials are conveyed via an 11-meter belt conveyor to an 80-type vertical semi-wet crusher. This equipment is specifically designed for high-humidity agricultural waste and mineral raw materials in Africa, employing a “high-speed impact + shearing grinding” composite process. The cutter head is made of high-chromium wear-resistant alloy, achieving a hardness of HRC60 or higher after heat treatment. It can crush large, agglomerated raw materials (particle size ≤80mm) into uniform fine materials ≤3mm, with a crushing efficiency of 4 tons/hour, meeting the stringent fineness requirements of subsequent granulation. The crusher features a sealed casing design, coupled with a negative pressure dust removal interface, effectively controlling dust leakage and improving the production environment.

Grading, Screening, and Transfer: The crushed raw materials are transferred via a 9-meter belt conveyor to the first 2.0×4.0-meter drum screen, which uses a single-layer high-precision screen design to separate substandard coarse particles. These particles are then returned to the crusher for reprocessing via a subsequent return system, achieving a material utilization rate of 98%. Qualified fine materials are transferred systematically via 6-meter, 5-meter, and 8-meter belt conveyors. These conveyors use wear-resistant, non-slip conveyor belts with anti-slip textures, adapted to Zambia’s hot and dry climate, preventing slippage and spillage during transfer, ensuring stable and reliable transfer efficiency.

Raw Material Mixing and Feeding Unit: Precise Control Ensures Uniform Granulation

High-Efficiency Mixing Process: The transferred raw materials enter a 40-type twin-shaft mixer. This equipment uses an anti-rotating blade design with a wear-resistant coating on the blade surface. During mixing, the materials undergo strong convection, shearing, and tumbling motions, ensuring thorough mixing of the main nitrogen, phosphorus, and potassium raw materials with trace element additives, achieving a mixing uniformity error of ≤2%. The mixer is equipped with a variable frequency speed control system, which can flexibly adjust the mixing speed (15-30 r/min) according to the moisture content and ratio of the raw materials. It also supports automatic material level monitoring and automatic unloading to prevent material overflow or insufficient mixing, ensuring continuous production.

Stable feeding control: The mixed material is conveyed to a 2200-type disc feeder via 9-meter and 6-meter belt conveyors. This feeder uses variable frequency speed control and material level sensor linkage control technology to precisely control the feed rate (adjustment range 1-3 tons/hour), ensuring uniform feeding to the three granulation units and avoiding granulation quality fluctuations or equipment overload caused by uneven feeding. The feeder disc surface features an anti-slip design, adaptable to raw materials with different flowability, ensuring stable operation without material jamming, and guaranteeing efficient subsequent granulation.

Core Granulation Unit: Three Main Units Working Together for Production Capacity Advantage

The core highlight of the production line is the collaborative operation of three granulators, including two conventional extrusion granulators and one twin-shaft extrusion granulator, forming a “multi-machine complementary, high-efficiency mass production” production mode. The conventional extrusion granulators employ a high-strength roller extrusion design, with roller skins made of high-chromium alloy, achieving a hardness of HRC62 or higher after quenching treatment, exhibiting extremely high wear resistance and extending service life to over 8000 hours. The twin-shaft extrusion granulator is optimized for highly viscous raw materials, employing a twin-shaft synchronous extrusion structure to enhance material plasticization and molding effects, adapting to a wider range of raw material characteristics.

All three granulators are equipped with a hydraulic pressure regulation system, allowing precise control of the extrusion pressure within the range of 6-18MPa. The granulation rate remains consistently above 92%, with uniform particle size controlled at 3-5mm and a compressive strength of 2.5MPa, preventing pulverization and fully meeting the needs of field application and long-distance transportation in Zambia. The three machines operate in tandem, with each machine producing 2 tons per hour, resulting in a total capacity of 6 tons per hour and a daily capacity of 144 tons, fully meeting the local demand for large-scale fertilizer production. The granulator is installed on a dedicated granulator platform (4.5 x 3.2 x 3 meters), designed to meet equipment maintenance and operational safety requirements while optimizing plant space utilization.

Grading and Finished Product Output Unit: Strict Quality Control and Efficient Delivery

Secondary Screening and Recycled Material Utilization: Granulated particles are transferred via a 10-meter belt conveyor to a second 2.0 x 4.0-meter drum screen. This screen features a double-layer design; the upper screen separates large, unqualified particles, while the lower screen selects qualified finished products. The screening efficiency reaches 7 tons per hour, with a 98% pass rate for qualified particles. Unqualified particles are returned to the raw material pretreatment stage via a 7-meter return conveyor, re-entering the production process, achieving resource recycling and effectively reducing production costs. The screening machine is equipped with an automatic screen cleaning device, which can clean the material adhering to the screen surface in real time, preventing screen blockage and ensuring stable screening efficiency.

Finished product storage and automated packaging: Qualified granules are conveyed to the finished product silo via a 10-meter belt conveyor. The silo adopts a sealed design and is equipped with ventilation and moisture-proof devices to effectively prevent fertilizer from absorbing moisture and clumping, ensuring product storage stability. The silo capacity can meet the finished product storage needs of continuous 5 hours of full-load production. The packaging process is equipped with an automatic packaging scale, supporting rapid switching between multiple packaging specifications such as 25kg and 50kg. It adopts the gravity metering principle, combined with a high-precision sensor, with a metering error ≤ ±0.2kg and a packaging speed of up to 80 bags/hour, realizing rapid quantitative packaging of finished products. Combined with the subsequent transfer system, it efficiently completes the warehousing and shipping of finished products.

Core Advantages and Regional Adaptability of the Production Line

High Adaptability, Unaffected by Complex Operating Conditions: Core equipment utilizes high-temperature, wear-resistant, and corrosion-resistant materials, adapting to Zambia’s hot and dry climate. Crusheres, mixers, and other equipment have optimized parameters for local raw material characteristics, capable of processing various raw materials such as livestock manure, mineral powder, and straw, demonstrating exceptional adaptability.

Stable and Reliable, Low Maintenance Costs: Key components employ standardized designs, and easily replaceable wear parts are readily available locally. The equipment boasts a low failure rate and an overall operating rate exceeding 95%. Furthermore, the company provides comprehensive technical guidance and spare parts supply services, significantly reducing customers’ subsequent maintenance costs.

High Efficiency and Environmental Protection, Meeting Local Standards: The entire production line utilizes energy-saving motors and optimized process design, reducing energy consumption by 12% compared to conventional production lines of the same capacity. Sealed equipment design and dust collection devices effectively control dust pollution during production, meeting Zambia’s local environmental protection requirements.

A Keystone Project for Modern Fertilizer Production in Africa

This successful Zambian project highlights Huaqiang Heavy Industry’s capability to deliver complete, localized professional fertilizer manufacturing equipment solutions. The installed extrusion granulation line serves as a versatile core for producing compound fertilizers, fitting seamlessly into the broader spectrum of global fertilizer production technologies.

Specifically, this line represents a robust npk fertilizer production line capable of executing the complete npk fertilizer production process. While it utilizes extrusion granulators, the same client needs could be met with other granulation technologies within Huaqiang’s portfolio. For instance, a disc granulation production line using a disc granulator (or disc granulator for shaping) is ideal for different material properties, while a roller press granulator production line offers another efficient dry compaction option. For operations requiring organic inputs, this NPK line can be integrated with feedstock from an organic fertilizer production line that might begin with a windrow composting machine. Furthermore, an npk blending machine is a fundamental component for precise formulation in any blended fertilizer operation, showcasing the interconnected nature of these fertilizer granulator and processing systems.

The successful commissioning of the extrusion granulation production line in Zambia not only demonstrates Zhengzhou Huaqiang Heavy Industry Technology Co., Ltd.’s comprehensive strength in the R&D of high-end granulation equipment and the implementation of overseas projects, but also provides efficient and stable equipment support for the modernization of agriculture in Africa. In the future, Huaqiang Heavy Industry will continue to focus on the production needs of different regions, optimize product performance and service solutions, and provide more competitive customized solutions for global customers, enabling “Made in China” to benefit the agricultural industries of more countries and regions.