From Traditional Composting to Intelligent Recycling Systems

Once upon a time, composting was considered a slow process requiring months and relying on manual management. Now, this is undergoing a revolutionary change. Modern composting technology is experiencing a technological revolution, moving from traditional to intelligent, from inefficient to high-speed, reducing organic waste processing time from months to 24-48 hours while maximizing resource utilization.

Precise Control of Intelligent IoT Systems

The application of IoT technology in composting is fundamentally changing the industry. At a large composting plant in California, the system is equipped with a deep sensor network: temperature sensors placed every meter monitor real-time temperature changes in the compost pile, humidity sensors precisely control the moisture content within the optimal range of 50%-60%, and gas sensors continuously track the emission concentrations of carbon dioxide, ammonia, and methane. This data is uploaded to a cloud platform in real time via a wireless network, allowing operators to check the compost status anytime via a mobile application.

A smart composting plant in Berlin, Germany, showcased an even more advanced application scenario. They used machine learning algorithms to analyze historical data, enabling them to accurately predict compost maturity time up to 48 hours in advance. When the system detects that the temperature of a batch of compost remains consistently below 40°C and the humidity is stable at around 45%, it automatically issues a maturity alarm, reducing production scheduling errors from 3-5 days in traditional methods to less than half a day. This precise control not only improves production efficiency but also ensures the stability of compost quality.

Technological Breakthroughs in High-Speed Automated Processing

A new generation of composting equipment is redefining the concept of “speed.” The high-speed organic waste conversion system introduced by the Tokyo Metropolitan Environmental Bureau in Japan uses a patented bio-enzyme formula and precise temperature control technology. Under a strictly controlled environment of 55-65°C, it can complete the decomposition process that traditionally takes 60 days in just 36 hours. This system processes 50 tons of food waste daily, producing 15 tons of high-quality compost, with a processing capacity more than 30 times that of traditional methods.

Advances in automated sorting technology have solved the problem of impurities in organic waste. A composting plant in London, UK, has deployed an artificial intelligence visual sorting system. Robotic arms equipped with high-resolution cameras can identify and sort contaminants such as plastics and metals at a rate of 3 times per second, achieving a sorting accuracy rate of 99.7%, ensuring the purity of the final product. In its first year of operation, the system has separated over 200 tons of impurities, significantly increasing the market value of compost products.

Sustainable Energy Utilization: Modern composting facilities are transforming from simple waste treatment sites into integrated energy centers. An advanced composting plant in Copenhagen, Denmark, employs a system design combining anaerobic digestion and aerobic composting. Organic waste first enters the anaerobic digester to produce biogas, generating 5,000 cubic meters daily, equivalent to providing electricity for 2,000 households. The remaining digestion residue is then processed through aerobic composting to produce nutrient-rich organic fertilizer, truly achieving zero emissions and full utilization of waste.

Heat Recovery Technology Further Enhances Energy Efficiency: A composting facility in Stockholm, Sweden, has installed an innovative heat exchange system that recovers heat generated during composting. It recovers the equivalent of 2.5 tons of standard coal daily, providing heating for nearby greenhouses, allowing them to continue producing vegetables even in winter, creating a virtuous cycle.

Innovation in Home and Small-Scale Applications

Composting technology is becoming more convenient than ever before in urban households. A company in Los Angeles, USA, has launched a smart composting device that resembles a small refrigerator. Using patented heating and grinding technology, it can convert kitchen waste into dry organic fertilizer in 8 hours. The device can be remotely monitored via a mobile app, and processing parameters are automatically adjusted according to the type of waste. It can process approximately 30 kilograms of kitchen waste per month for a family of four.

Advances in microbial technology are providing new solutions for urban composting. A specialized microbial agent developed in Singapore can rapidly decompose organic matter in confined spaces, operating efficiently even on apartment balconies. This agent contains specially selected heat-resistant microorganisms that remain active within a temperature range of 45-70°C, shortening the composting cycle to less than 72 hours.

A Global Example of Innovation

In Melbourne, Australia, a solar-powered smart composting station is changing how communities manage waste. The station is entirely powered by solar energy and equipped with an automatic monitoring and control system; residents can use it simply by swiping a card. The system automatically records each user’s usage and output, awarding points based on contributions and motivating public participation in composting.

The “Smart Compost Bin” project promoted in Seoul, South Korea, showcases a perfect integration of IoT technology and public services. These compost bins, distributed across various communities, monitor their filling status and composting progress in real time, automatically notifying administrators when maintenance is needed. Residents can check the location and current status of the nearest available compost bin via a mobile app, significantly improving system efficiency.

From traditional open-air storage to today’s intelligent, high-speed processing, the evolution of composting technology not only represents technological progress but also reflects humanity’s pursuit of sustainable development. This ongoing technological revolution is transforming organic waste from an environmental burden into a valuable resource, providing a practical technological path to building a circular economy and achieving carbon neutrality.

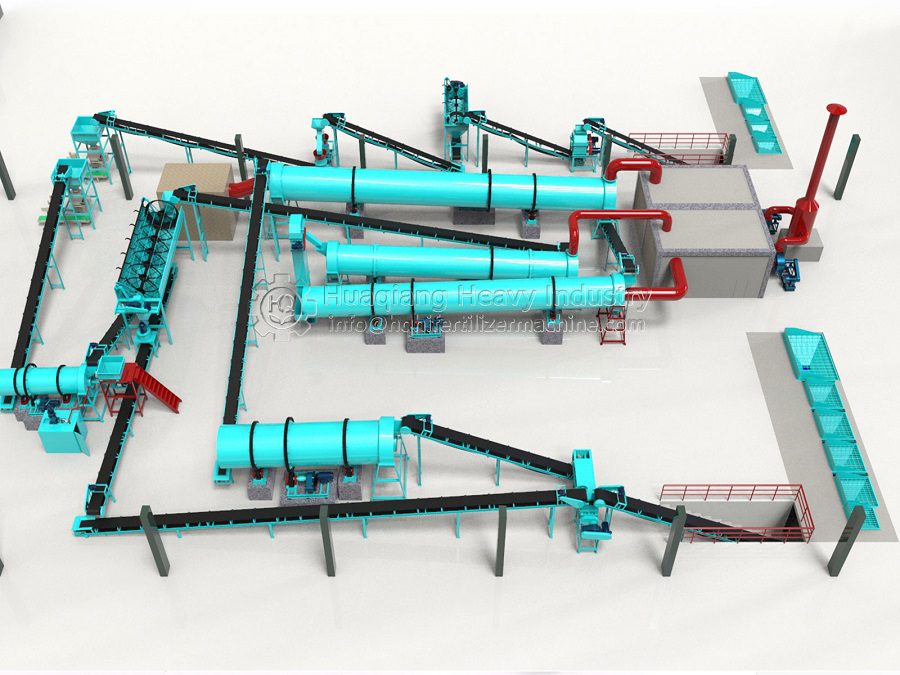

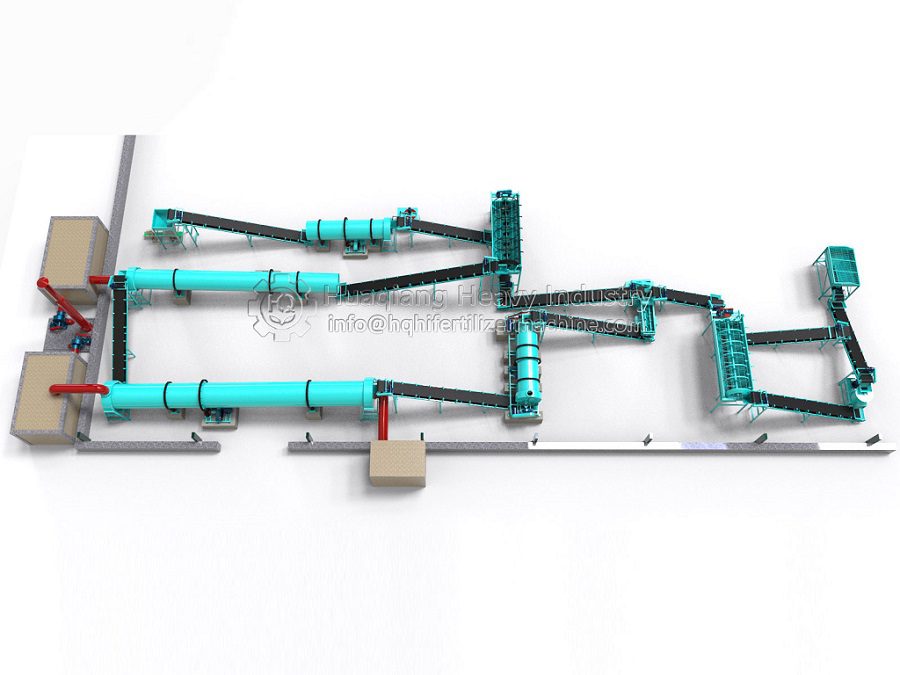

Scaling Smart Composting for Commercial Fertilizer Production

The IoT and rapid composting innovations described are often the foundation for industrial-scale fermentation composting technology for organic fertilizer. In a commercial setting, these smart principles are applied to larger machinery. The advanced fermentation composting turning technology might be executed by a high-capacity windrow composting machine like a large wheel compost turner or a chain compost turner for open windrows, or a more controlled self propelled compost production machine. For the highest intensity and control, trough-type aerobic fermentation composting technology is employed. This entire mechanized system is an agriculture waste compost fermentation machine designed for volume.

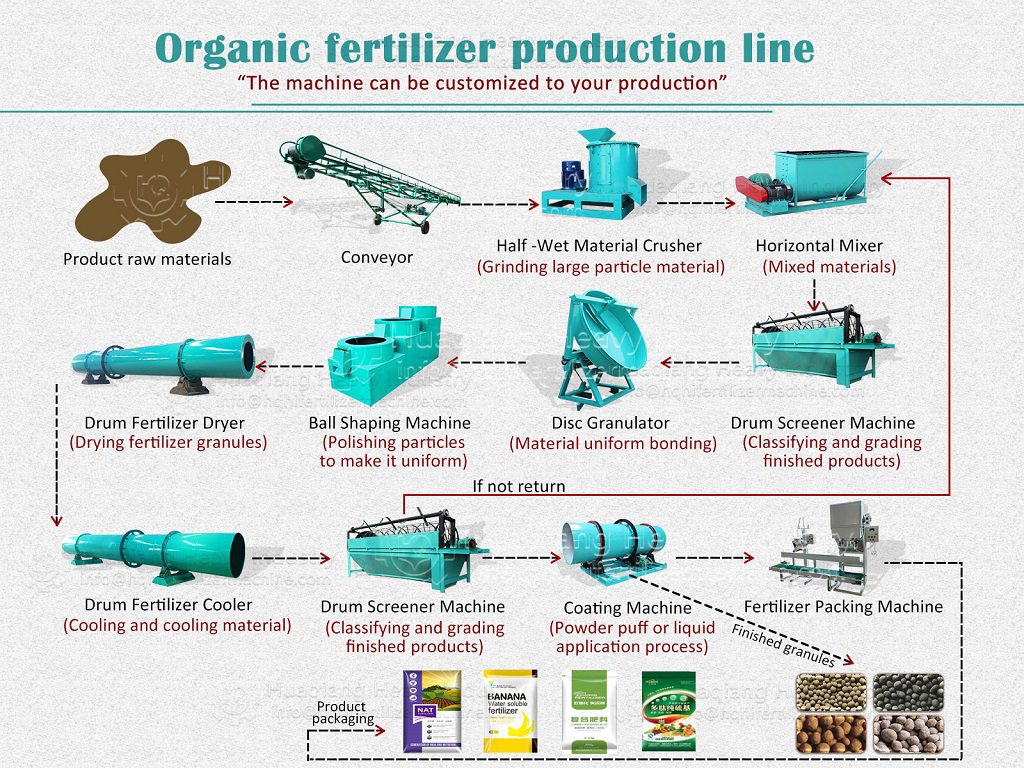

The high-quality, stabilized compost produced then enters the next value-addition phase as part of the equipments required for biofertilizer production. To transform this compost into a market-ready product, it is typically granulated. A common method is the disc granulation production line, which shapes the moist compost into uniform, spherical pellets ideal for storage and application. This creates a complete, technology-driven pathway from intelligent waste processing to a standardized agricultural input.

Therefore, the future of composting lies in the synergy between smart, data-driven decomposition systems and efficient downstream processing equipment. This integrated approach maximizes both the speed of resource recovery and the economic value of the final product, supporting a true circular economy in agriculture.