Smart Investment, Avoiding Procurement Traps

In fertilizer production line investment, the choice of granulator directly impacts product quality, production efficiency, and return on investment. With a wide variety of equipment on the market and significant price differences, avoiding procurement pitfalls and selecting truly high-performance equipment has become a crucial issue for investors. This article provides a systematic purchasing guide from multiple dimensions, including technology, economics, and service.

I. Defining Needs: Four Key Analyses Before Purchase

1. Product Positioning and Process Matching

Primary Considerations:

Fertilizer Type: Organic fertilizer, compound fertilizer, and bio-fertilizer each have suitable machine models

Raw Material Characteristics: Fiber content, moisture range, differences in adhesiveness

Capacity Requirements: Current demand and future expansion plans

Pellet Requirements: Pellet size specifications, strength standards, appearance

Matching Recommendations:

Roller Granulator: Suitable for large-scale NPK compound fertilizer production

Disc Granulator: Suitable for small and medium-sized organic fertilizer production lines

Double Roller Extruder: Suitable for heat-sensitive raw materials and specialty fertilizers

2. Production Condition Assessment

Site Limitations: Equipment size and plant matching

Energy Supply: Power capacity, steam pressure requirements

Environmental Requirements: Dust and noise emission standards

Operational Level: Automation level and personnel skill matching

II. Core Parameters: Performance Indicators That Must Be Monitored

1. Technical Performance Specifications

Pelletizing Quality Parameters:

Pelletizing Rate: High-quality equipment should achieve 85% or higher

Pellet Strength: Standard pellet compressive strength ≥15N

Pellet Size Uniformity: Qualification rate should exceed 90%

Return Rate: Ideally controlled within 15%

Production Efficiency Parameters:

Rated Capacity: Requires a 20% margin in the design

Energy Consumption: Electricity consumption per ton of product, steam consumption

Continuous Operating Time: High-quality equipment should be able to operate continuously for over 720 hours

2. Key Component Configuration Standards

Transmission System:

Gearbox Brand: International brands such as SEW and Flender, or equivalent domestic brands

Bearing Configuration: Well-known brands such as SKF and NSK

Motor Protection Rating: IP55 or higher, F-class insulation

Main Body Material:

Parts in Contact with Materials: 304/316 stainless steel

Structural Components: Q235B or higher carbon steel, thickness meets standards

Wear-Resistant Treatment: Wear-resistant layer welded to key parts

III. Cost Analysis: Life Cycle Cost Accounting

1. Identifying Procurement Cost Traps

Low-Price Trap Warnings:

Material Downgrading: Using non-standard steel or substandard stainless steel

Component Downgrading: Using inferior bearings and ordinary motors

Simplified Processes: Omitting necessary heat treatment processes

Lack of Service: Not including installation, commissioning, or technical training

2. Actual Cost Breakdown

Initial Investment:

Equipment Purchase Cost: 60-70% of total cost

Installation and Commissioning Cost: Typically 8-12% of equipment price

Ancillary Equipment Cost: Dust removal, conveying, and other auxiliary systems

Operating Costs:

Energy Costs: Electricity and steam consumption

Maintenance Costs: Replacement of wear parts, regular maintenance

Labor Costs: Operator staffing requirements

Calculation Example: One model of granulator is priced at 300,000 yuan, another model at 400,000 yuan

Lower-priced equipment: Annual maintenance cost 40,000 yuan, energy consumption 20% higher

High-quality equipment: Annual maintenance cost 15,000 yuan, energy consumption lower

Total cost over 3 years: Lower-priced equipment = 300,000 + 120,000 + energy consumption premium; High-quality equipment = 400,000 + 45,000. Calculations show that the high-quality equipment is actually more cost-effective.

IV. Supplier Evaluation: Seven Key Considerations

1. Technical Strength Verification

Check Patent Certificates: Must possess at least 3 relevant patents

Inspect Production Base: Production scale, equipment precision, quality control system

Require On-site Trial Run: Use in-house raw materials for production verification

2. Success Case Verification

On-site Visit: Visit at least 3 operating projects

Customer Interviews: Understand the actual operation of the equipment

Operating Data: Obtain continuous operation records and output data

3. Service Capability Assessment

Pre-sales Service:

Professionalism of Solution Design

Detailed Technical Disclosure

Customization Capability

After-sales Service:

Response Time: Committed to no more than 24 hours

Spare Parts Supply: Inventory status of commonly used spare parts

Technical Training: Systematic training system

V. Contract Signing: Key Clauses and Considerations

1. Clear Technical Annexes

Detailed Technical Parameter List

Confirmation of Key Component Brands

Performance Guarantee Indicator Data

2. Detailed Acceptance Standards

No-load Test Run Requirements

Load Test Run Standards

Capacity Verification Methods

3. Strict Warranty Terms

Warranty Period: At least 12 months

Warranty Scope: Clearly defined contents

Fault Response: Specific time commitment

VI. Procurement Implementation: Five-Step Process Control

Requirements Confirmation: Detailed technical specifications prepared

Market Research: Screening 3-5 qualified suppliers

Solution Comparison: Organizing technical solution review meetings

Business Negotiation: Comprehensive evaluation of price and service

Contract Execution: Strictly adhering to contract milestones

VII. Lessons from Successful Cases

Procurement Experience of a Fertilizer Company in Shandong:

Initial Selection of Low-Priced Equipment: 250,000 RMB

Operational Problems: Frequent breakdowns, annual maintenance costs exceeding 60,000 RMB

Insufficient Capacity: Actual capacity only 80% of nominal capacity

Re-procurement: Selecting high-quality equipment priced at 380,000 RMB

Results Comparison: 80% reduction in failure rate, capacity achieved target, return on investment within 2 years

Choosing the Right Granulation Technology: A Strategic Investment

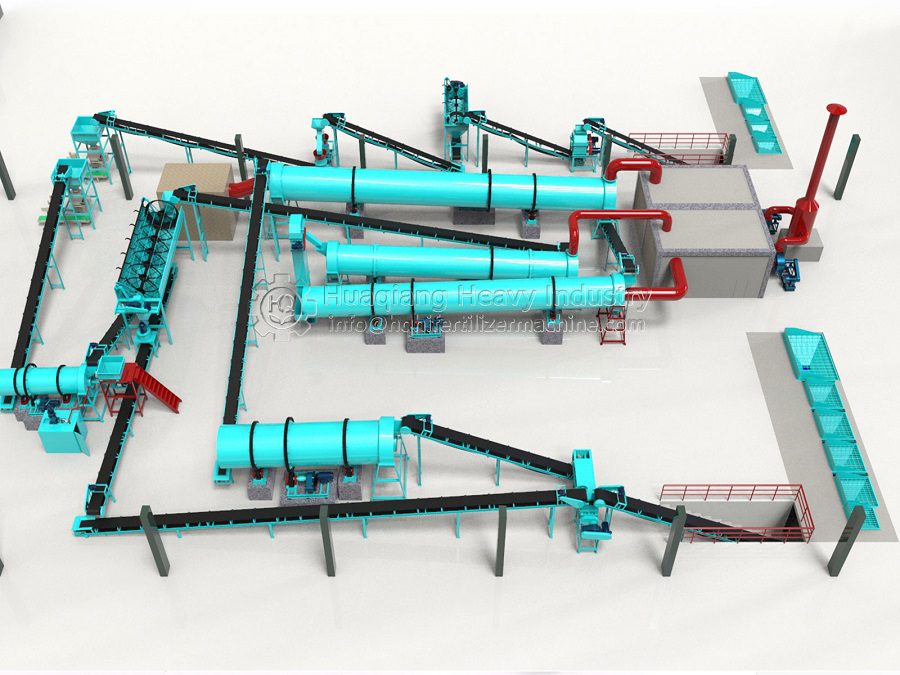

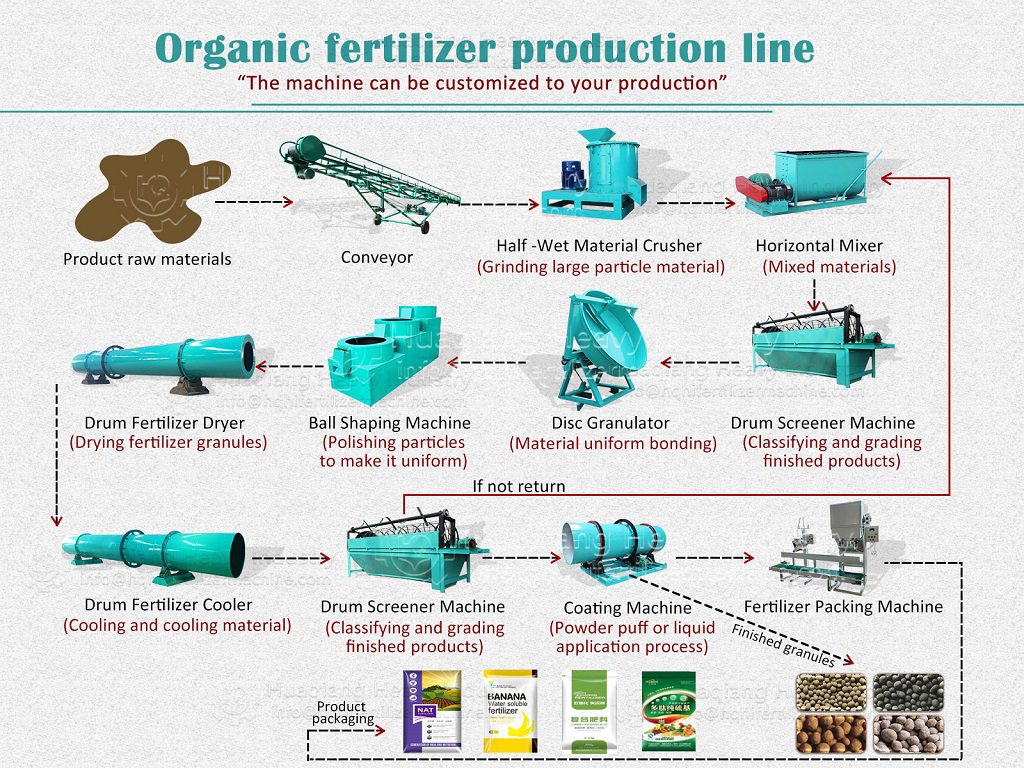

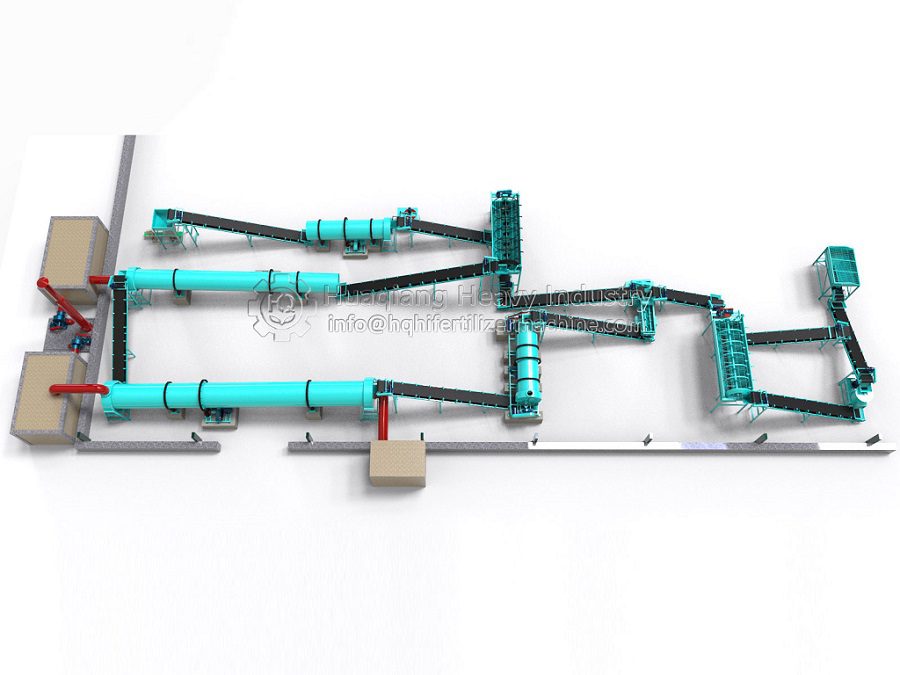

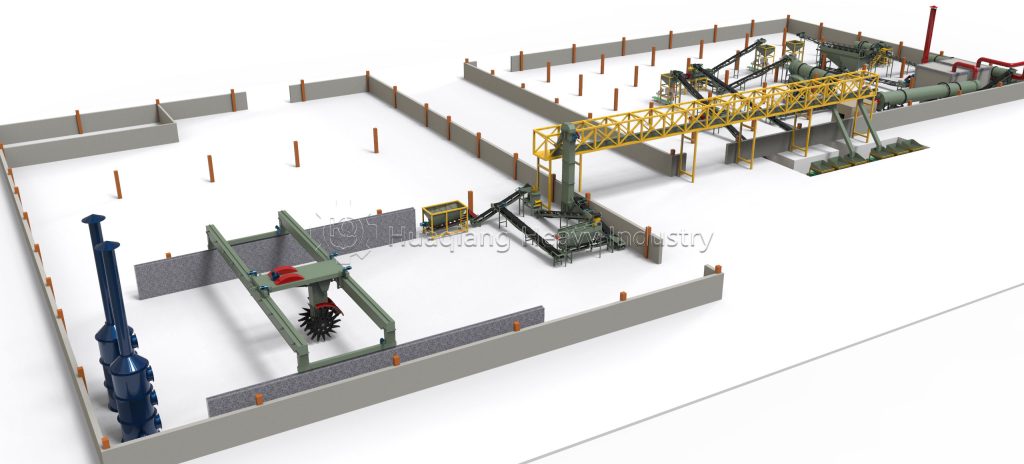

The procurement guide highlights the critical decision between fundamentally different granulation technologies within the npk fertilizer manufacturing process. One primary pathway is the roller press granulator production line, a system based on fertilizer granules compaction. This method uses a high-pressure fertilizer compactor (or fertilizer compaction machine) for dry fertilizer compaction, eliminating the need for drying. The alternative mainstream technology for large-scale npk manufacturing process operations is the rotary drum granulator, which uses wet agglomeration with binders.

This choice is a core strategic investment. The roller press line offers lower energy consumption but may produce less spherical granules. The drum granulator offers high capacity and spherical shape but requires more energy for drying. The selection must align with the specific product goals, raw material characteristics, and total cost of ownership analysis outlined in the procurement guide. For operations requiring gentle shaping of organic materials, other technologies like a disc granulator for shaping might be more appropriate. Therefore, a “one-size-fits-all” approach is a trap; the investment must be in the technology that best fits the defined production needs and long-term economic model.

Ultimately, the most cost-effective investment is not the cheapest machine, but the most appropriate technology package—comprising the right granulation principle, robust components, and reliable service—that ensures efficient, stable, and profitable production over the equipment’s entire lifecycle.

Conclusion: Value investment is better than price-based procurement. When purchasing granulators, a full life-cycle cost concept should be established to avoid falling into the trap of simply comparing prices. True cost-effectiveness is a comprehensive balance of performance, quality, service, and price. Investors are advised to:

Conduct thorough research into their own actual needs;

Establish a scientific evaluation system;

Pay attention to the overall strength of suppliers;

Focus on the long-term operational benefits of equipment.

Remember: The cheapest equipment is often the most expensive investment, while the most suitable equipment is the true cost-effective choice. Through rational analysis and scientific decision-making, companies can not only avoid procurement pitfalls but also lay a solid foundation for long-term stable production, maximizing investment returns.