.jpg)

Equipment Overview and Core Structure

Rotary drum thickeners are essential equipment based on solid-liquid separation principles, widely used in wastewater treatment, mineral processing, and chemical production. The core components include a horizontally mounted cylindrical drum, drive system, filtrate collection chamber, and sludge discharge mechanism. The drum surface is typically covered with filter media or designed for gravity sedimentation, achieving efficient solid-liquid separation through slow rotation.

Detailed Working Process

The operation of rotary drum thickeners can be divided into four key stages. First, slurry is pumped into the slurry tank, partially submerging the drum. During the separation phase, the drum rotates slowly at 5-10 rpm, with solid particles being retained by the filter media or deposited on the drum surface through gravity sedimentation, while clarified liquid enters the collection system. As the drum rotates out of the slurry, scraper devices remove the concentrated solid layer, enabling continuous production cycles.

Related Applications in Fertilizer Production

Although rotary drum thickeners are primarily used for solid-liquid separation, their principles are closely related to other equipment in NPK fertilizer production lines. In the complete NPK fertilizer manufacturing process, the rotary drum granulator serves as the core equipment, responsible for forming uniform granules from mixed raw materials through drum granulation technology. Similar to rotary drum thickeners, rotary drum granulators also rely on precisely controlled rotation speeds and process parameters to ensure product quality.

In the NPK fertilizer production process, raw materials are first uniformly mixed through NPK blending machines, then enter the rotary drum granulator for granulation. The granulated material requires subsequent processing including drying, cooling, and screening. The rotary screener functions similarly to the rotary drum thickener in principle, both utilizing rotational motion for material separation and classification. Whether using disc granulators or rotary drum granulators, the basic principle involves using mechanical motion to promote effective material processing.

Key Technical Parameters and Control

Efficient operation of rotary drum equipment relies on precise control of multiple key parameters. Rotation speed is one of the most important parameters, typically maintained within 1-15 rpm to ensure sufficient processing time without disrupting the formed solid layer. Submergence depth directly affects the contact time between equipment and materials, consequently impacting processing efficiency. For filtration-type equipment, filter media selection needs optimization based on solid particle size to prevent clogging and ensure processing effectiveness.

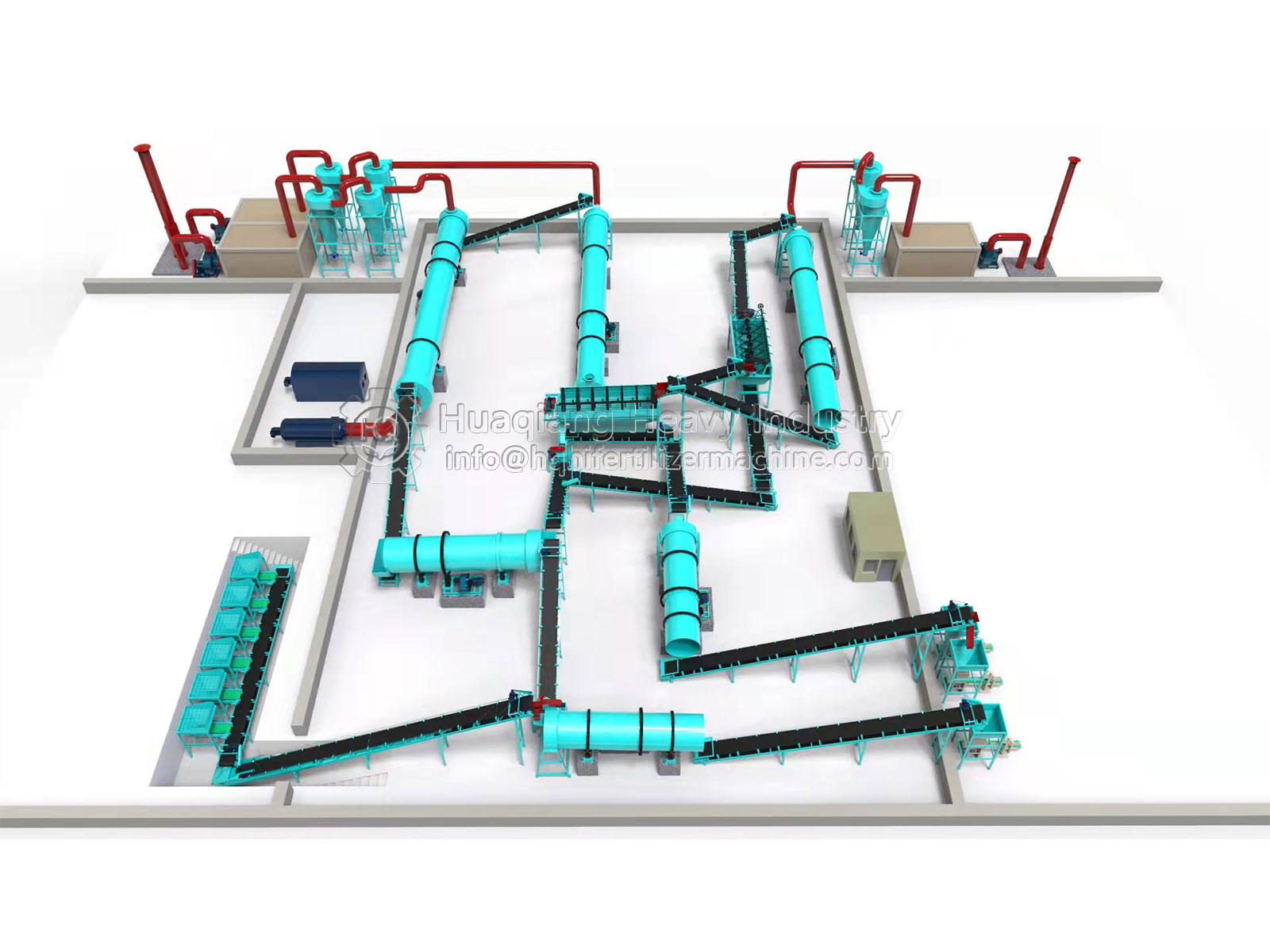

Integration in Fertilizer Production Systems

In modern NPK fertilizer production technology, various rotary drum equipment collectively form a complete production system. NPK bulk blending machines handle initial raw material mixing, fertilizer mixer machines ensure uniform distribution of components, and rotary granulators achieve final particle formation. The entire NPK fertilizer production process requires coordinated operation of all equipment, forming an efficient and continuous NPK production line from raw material processing to finished product packaging.

Process Advantages and Development Trends

Rotary drum technology demonstrates significant advantages in various industrial processing applications. Its continuous operation characteristics ensure production stability, while modular design provides excellent process flexibility. With the development of automation technology, modern rotary drum equipment integrates advanced monitoring systems capable of real-time parameter adjustment to optimize the NPK fertilizer production process. Whether used for solid-liquid separation in rotary drum thickeners or for granulation in rotary drum granulators, the technology is evolving toward higher efficiency and energy savings.

Maintenance and Operational Essentials

To ensure long-term stable operation of rotary drum equipment, a comprehensive maintenance system must be established. Regular inspection of mechanical transmission components, monitoring filter media condition, and timely cleaning of accumulated materials are all essential maintenance tasks. In NPK fertilizer production equipment operation, personnel require professional training to understand equipment characteristics and process requirements, enabling full utilization of equipment performance and ensuring smooth NPK fertilizer manufacturing process operation.

Conclusion

As important solid-liquid separation equipment, rotary drum thickeners provide reliable solutions for industrial processing applications. In the fertilizer production sector, rotary drum technology applications extend beyond thickening processes to multiple key stages including granulation and mixing. With the continuous development of NPK fertilizer production technology, rotary drum equipment will continue to play a vital role in improving production efficiency and optimizing product quality, providing solid technical support for modern chemical production.