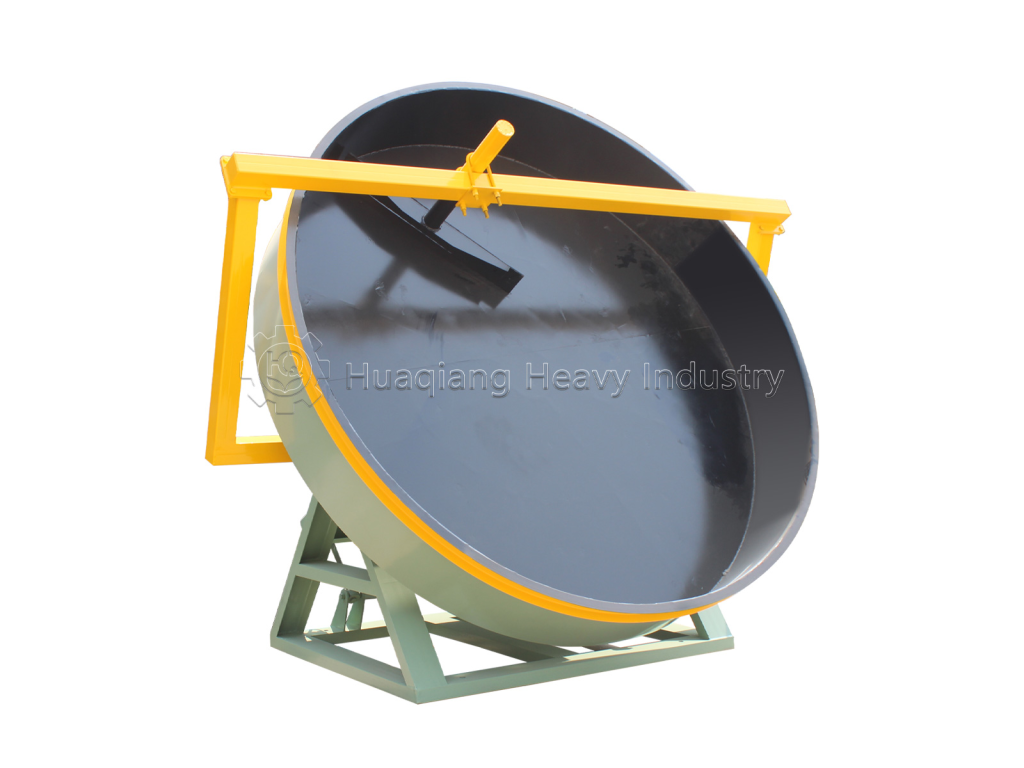

Disc Granulator: The Core Powerhouse of Fertilizer Production

In modern fertilizer production lines, the disc granulator acts like a skilled “magician,” transforming various raw materials into perfectly uniform granules. As the core equipment for producing organic fertilizer, organic-inorganic compound fertilizer, chemical fertilizer, and biofertilizer, it is revolutionizing the entire fertilizer manufacturing industry.

When organic fertilizer processed by disc granulator is applied to soil, the organic matter content increases significantly, followed by an increase in soil organic nitrogen. This virtuous cycle not only improves soil structure but also creates an ideal environment for crop growth. The three major advantages of disc granulation—uniform particles, easy moisture control, and high granule strength—make it the preferred choice for fertilizer manufacturers.

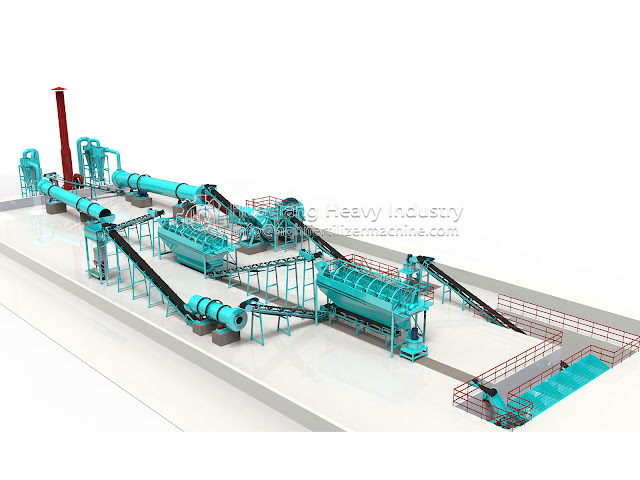

The Ingenious Combination of Disc Granulation Line

A complete disc granulation production line is a perfect example of multiple precision equipment working in harmony. Each machine plays an indispensable role in ensuring the excellent quality of the final product:

1. Disc Granulator – The heart of the production line, responsible for transforming mixed materials into uniform granules

2. Horizontal Mixer – Ensures thorough and uniform mixing of various raw materials

3. Drum Screening Machine – Precise grading to ensure consistent particle size

4. Coating Machine – Provides a “protective coat” for granules to prevent caking

5. Multiple Silos Single Weigh Static Automatic Batching System – Accurately controls formula ratios

6. Automatic Packing Machine – Efficiently completes product packaging

Why Choose Disc Granulation Technology?

Compared with traditional granulation methods, disc granulation technology offers incomparable advantages. Its unique tilted rotating design creates ideal rolling motion of materials in the disc, resulting in uniform granulation. Operators can easily control particle size and moisture content by adjusting parameters such as disc inclination angle, rotation speed, and water spray volume to meet different customer requirements.

Even more exciting is the disc granulator’s strong adaptability to raw materials—whether powdered organic matter or chemical materials, it can handle them perfectly. This flexibility allows manufacturers to quickly switch between different product formulations to seize market opportunities.

Investing in a disc granulation production line is not just about purchasing equipment; it’s about injecting strong momentum into your company’s future development. In today’s world of increasingly stringent environmental requirements and booming organic agriculture, this efficient and flexible production system will become your secret weapon to conquer the market!