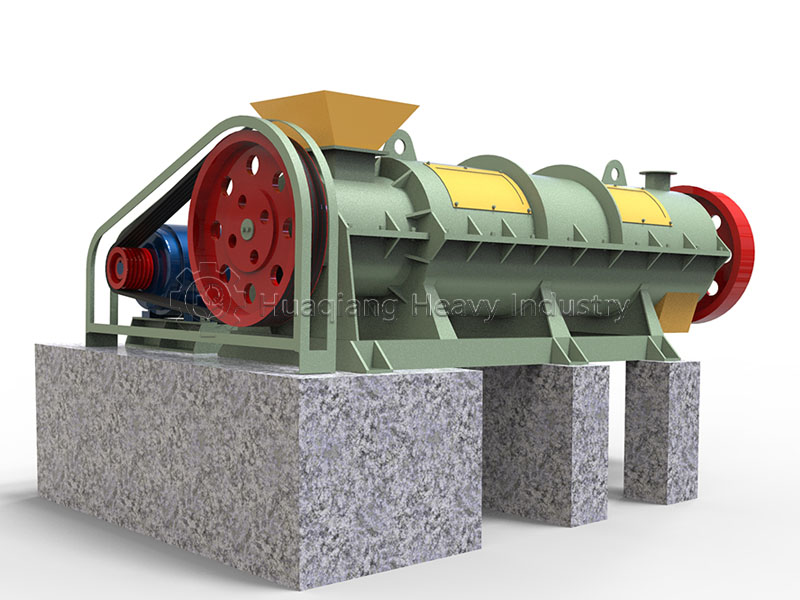

Optimizing double roller press granulator process to boost organic fertilizer production

Double roller press granulators are key equipment in modern organic fertilizer production lines. Optimizing their process directly impacts a company’s output and economic benefits. With the rapid growth of organic farming, how to improve organic fertilizer production through technical upgrades to these granulators has become a major focus for many manufacturers.

1.Optimizing Raw Material Pre-treatment

Grind raw materials to 40-60 mesh. Control moisture content between 20%-25%. Adding suitable binders like bentonite or lignin can significantly improve granulation rate and reduce return material. This is expected to increase output by around 15%.

2.Precise Adjustment of Roller Parameters

For general organic fertilizer production: Set the nip gap between 1.5-2.5mm. Maintain roller pressure at 8-12MPa. Control line speed at 0.8-1.2m/s. Installing pressure sensors and automatic adjustment systems allows for dynamic optimization, improving particle formation rate.

3.Die Selection and Maintenance

Hole Size: 3-6mm suits most organic fertilizers. Open Area Ratio: Maintain between 30%-40%. Regular polishing extends die life. Recommend professional maintenance every 500 tons of material processed to ensure smooth discharge.

4.Coordinated Optimization of Supporting Equipment

Precise batching system (error <1%). Efficient mixer (mixing uniformity >95%). Energy-saving dryer (thermal efficiency >65%). Systematic upgrades like this can increase the entire line’s output by 30%-50%.

Through comprehensive optimization of the double roller press granulator process, organic fertilizer producers can significantly boost production without adding more machines.