Advantages and disadvantages of BB fertilizers: Value determined by suitability

BB fertilizers, or blended fertilizers, are made by mixing two or more single-element fertilizers or compound fertilizers in a specific ratio. They require no complex granulation process and their flexibility has secured them a place in agricultural production.

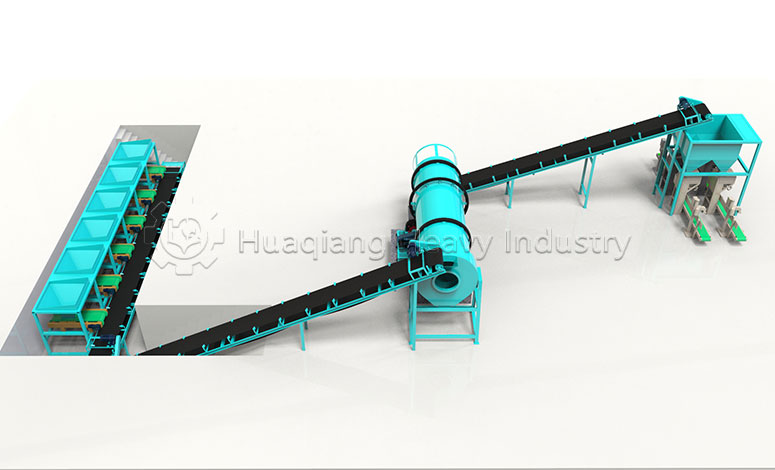

The core advantages of BB fertilizers are their flexibility and economy. Formulas can be customized to precisely suit different soil fertility levels and crop needs, adjusting the proportions of nitrogen, phosphorus, potassium, and trace elements. Their adaptability far exceeds that of fixed-ratio compound fertilizers, making them particularly suitable for specialty crops and regional soil improvement. The production process is simple; the core blending process can be completed using a BB fertilizer mixer, eliminating the need for complex granulation equipment and a complete NPK blending fertilizer production line. This significantly reduces processing costs and ensures high raw material utilization, minimizing nutrient waste.

The disadvantages stem from the inherent limitations of their blending characteristics. They have poor physical stability; different raw materials have varying particle sizes and specific gravities. Even after being uniformly mixed in a BB fertilizer mixer, they are prone to stratification and clumping during transportation and storage, affecting the uniformity of fertilization and leading to uneven crop growth. Uncoordinated nutrient release and lack of synergistic slow-release effect can easily lead to partial nutrient loss and insufficient supply. It also requires high purity of raw materials and precise blending.

In summary, BB fertilizer is suitable for small-scale, personalized planting scenarios, accurately matching differentiated needs. In large-scale, standardized planting, it needs to be paired with professional fertilizer production equipment to control the precision of the ratio and to manage storage effectively in order to avoid shortcomings and maximize advantages.