NPK fertilizer mixing technology: From homogeneous slurry to precision blending

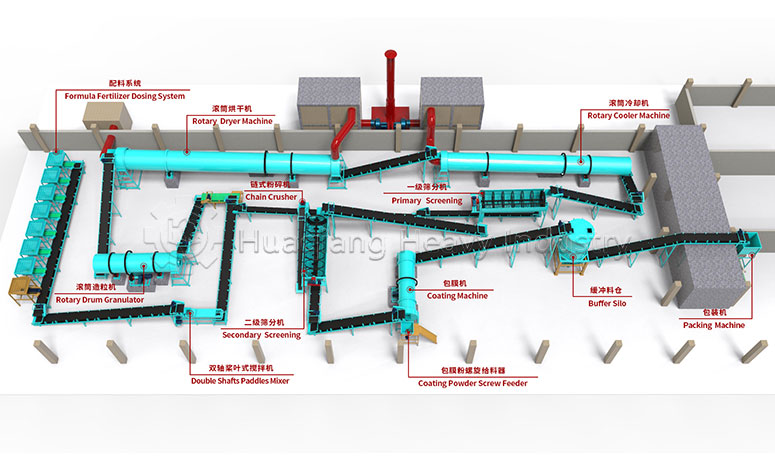

In modern NPK fertilizer production, the mixing process is not merely simple stirring, but a core technology permeating the entire production process. It directly determines the uniformity of nutrient distribution, affecting the stability and fertilizer efficacy of the final product. From liquid to solid, from chemical to physical, the mixing process, in its diverse forms, supports the production quality of compound fertilizers.

In the initial stages of production, the chemical reaction itself is accompanied by deep mixing of raw materials. When the basic nitrogen, phosphorus, and potassium raw materials undergo chemical reactions under specific conditions, continuous mechanical stirring ensures sufficient contact between the reactants. The homogeneous slurry formed in this process lays the necessary physical foundation for subsequent granulation.

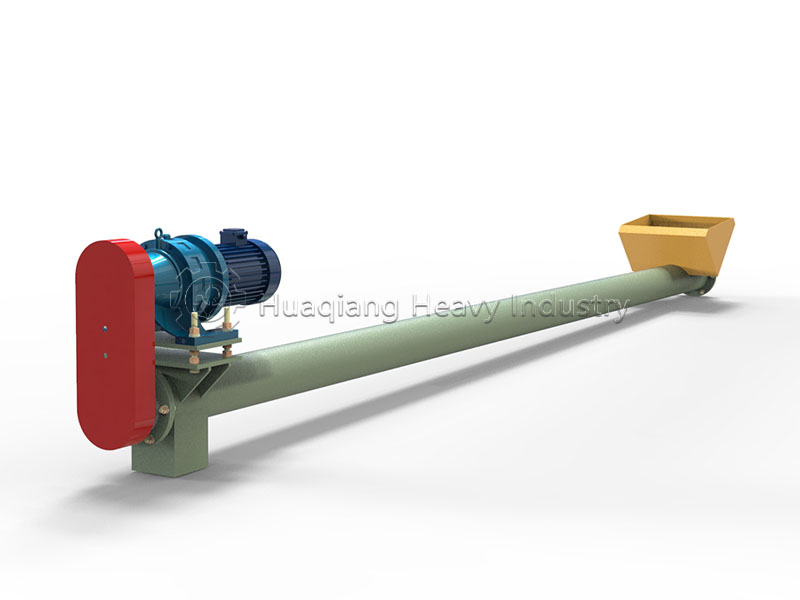

After chemical mixing, the materials enter the refined physical mixing stage. When the slurry or powder needs to be combined with other auxiliary materials, specialized fertilizer mixer machines, through scientifically designed motion trajectories, can achieve a highly uniform distribution of each component in a short time.

In another important branch of NPK fertilizer production—the production of physically blended fertilizers (BB fertilizers)—NPK fertilizer production technology exhibits different technical requirements. Faced with basic fertilizer granules of varying densities and sizes, the mixing process must achieve both uniform nutrient distribution and minimize granule breakage and separation. This targeted mixing technology enables the perfect coexistence of various granule types.

From mechanical stirring in the chemical reactor to the uniform distribution of the finished granules, the mixing process remains a crucial node in the NPK fertilizer production line. Its technological advancements not only improve the intrinsic quality of fertilizer products but also provide a reliable material foundation for the development of precision agriculture.