The value of high-quality organic fertilizer production machines for palm fiber and animal manure

Palm fiber is tough and degrades slowly, while animal manure is rich in nutrients but prone to clumping and odor. Producing organic fertilizer from these two materials requires specialized equipment to overcome these raw material challenges. High-quality organic fertilizer production machines, with their targeted design, can neutralize the shortcomings of both raw materials and maximize the value of their nutrients.

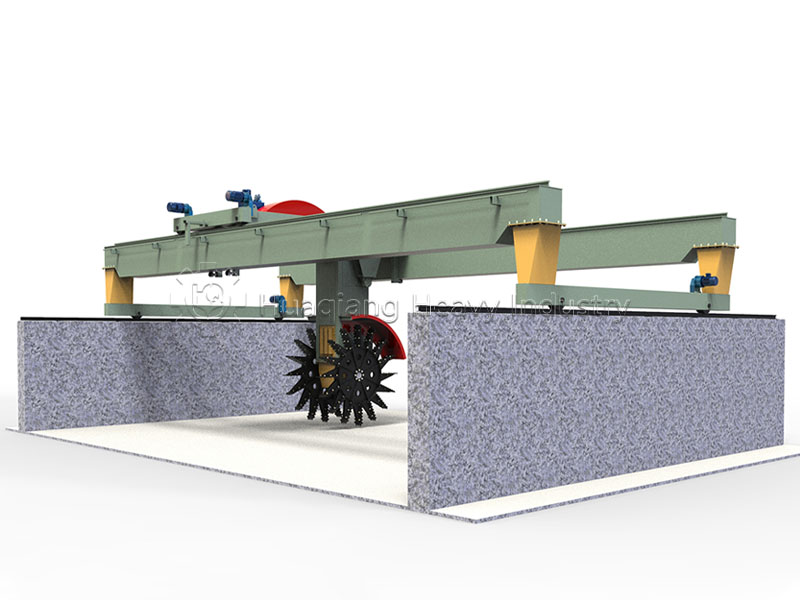

Precise adaptation to raw material characteristics. The equipment is equipped with a high-strength fertilizer crusher that can break down tough palm fibers into fine particles while simultaneously breaking up clumps of animal manure, ensuring uniform mixing. To address the imbalance in the carbon-nitrogen ratio of the mixed raw materials, the equipment can be linked to a batching system for precise adjustment, creating the optimal environment for microbial fermentation.

Fermentation and granulation stages. The fermentation stage utilizes a temperature and humidity control system to maintain high-temperature composting at 55-65℃, which kills pathogens and insect eggs while accelerating the degradation of palm fiber and preserving the organic matter and trace elements in the raw materials. The granulation stage is adapted to the loose characteristics of the mixed raw materials, optimizing pressure and rotation speed to produce granules with uniform strength and high sphericity.

Closed-loop process ensures product quality. The organic fertilizer production equipment integrates pre-treatment, fermentation, granulation, and cooling functions. The resulting organic fertilizer has excellent breathability and long-lasting fertilizer efficiency, improving soil aggregate structure and providing comprehensive nutrition for crops, achieving efficient resource utilization of palm fiber and animal manure.