What is the role of screening in the organic waste treatment process?

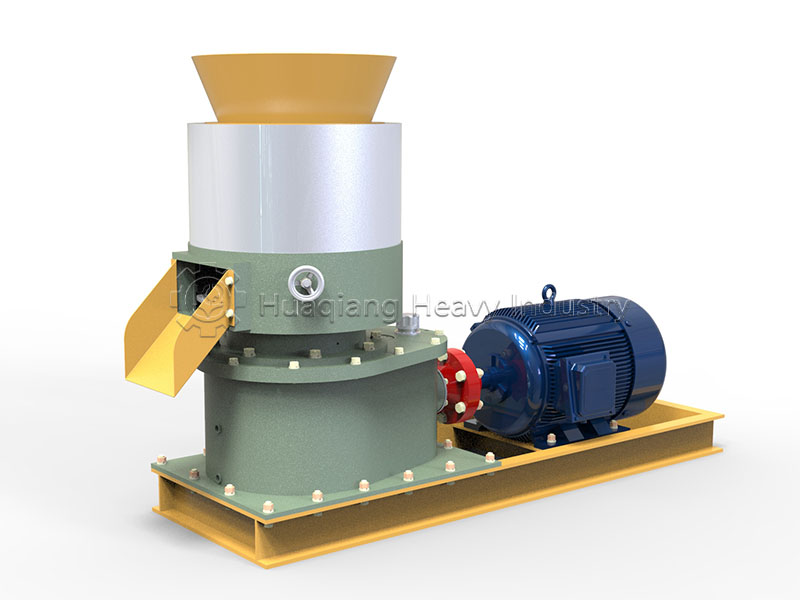

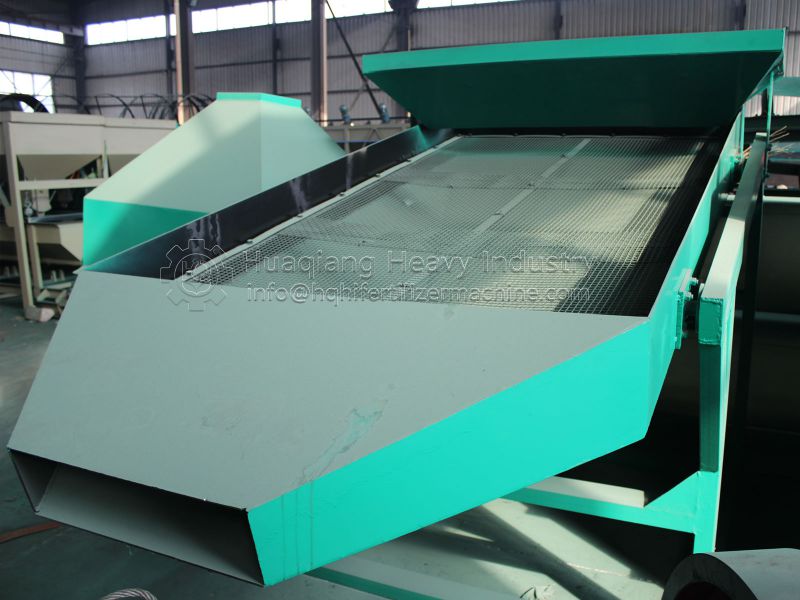

In the entire organic waste treatment process, screening is a core pre-treatment step, requiring specialized equipment such as drum screener machine or vibration screener machine. Its core value lies in removing impurities and optimizing material characteristics through physical classification, laying a solid foundation for subsequent processes such as fermentation and resource utilization.

The primary function is to remove impurities and ensure the safe and smooth operation of equipment. Inert impurities such as stones, metals, and plastics mixed in organic waste can easily wear and clog equipment such as fermentation tanks and mixers. Precise screening with a fertilizer screener machine effectively separates impurities, reduces operating and maintenance costs, and ensures a continuous and stable treatment process.

Secondly, it involves material classification to optimize the effectiveness of subsequent processes. Organic waste of different particle sizes has significantly different fermentation efficiencies. Screening can classify materials by particle size: fine materials can fully contact microorganisms and oxygen, improving the speed and uniformity of composting; coarse materials can be returned to the crushing system for reprocessing, preventing incomplete fermentation and uneven nutrient distribution in the final product.

Furthermore, screening improves the quality of resource-recovered products. When producing organic fertilizer from organic waste, fine screening with a fertilizer screener machine removes uncomposted coarse particles and residual impurities, ensuring uniform particle size and purity of the organic fertilizer. At the same time, the materials classified by drum screener machine and vibration screener machine can be adapted to different resource utilization pathways, improving resource utilization efficiency.

In summary, screening is a crucial link connecting the pre-treatment and deep treatment of organic waste, playing an irreplaceable role in improving treatment efficiency, reducing costs, and ensuring resource utilization value.